Subsections

The simulator is implemented by first calculating the shape of the nanodot or nanowire

with the previously mentioned empirical equations which

depend on the oxidation time, applied voltage, ambient humidity, and nanowire orientation.

Afterwards, a given number of particles is distributed above the silicon surface,

their position following the pattern of the desired surface deformation. Finally, each particle

is accelerated towards the surface, causing it to collide with the wafer. Upon impact, the silicon

dioxide is advanced deeper into the silicon, while it simultaneously grows into the ambient. The result

is an oxide nanodot or nanowire having the desired height and width, depending on the processing variables

of voltage, time, humidity, and orientation. The method of imprinting a desired particle distribution

onto a wafer surface is represented graphically in Figure 3.19.

Figure 3.19:

Image representation of the MC method of ``imprinting'' a desired particle distribution onto the silicon

surface in order to generate an oxide growth. The particles are accelerated using ray tracing techniques within

the LS simulator environment.

|

![\includegraphics[width=\linewidth]{chapter_process_modeling/figures/AFM_distribution.eps}](img470.png) |

A flow chart summarizing the simulation steps is given

in Figure 3.20, which describes how the desired particle distribution is effectively imprinted

onto the LS surface using the MC method.

Figure 3.20:

Flow chart of the simulation process implementing the Monte Carlo method with ray tracing in a LS environment.

![\includegraphics[width=0.9\linewidth]{chapter_oxidation_modeling/figures/flowchart.eps}](img471.png) |

As seen from the previous discussion regarding the MC model for AFM oxidation from Figure 3.20,

a method to distribute particles according to a desired distribution is required.

Some literature approximate the final oxide dot topography with a Gaussian curvature [162], while some suggest a

Lorentzian profile [84].

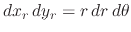

The quantile function of the one-dimensional Gaussian distribution, required for the generation

of a random particle position  , is

, is

erf erf |

(123) |

Because of the error function, the quantile Gaussian function is not easily implementable with a random distribution

in the MC environment

and hence another model is desired. The model implemented in the simulator is based on the well known

Marsaglia polar method [139]. This method suggests a way to generate two

independent standard normal random variables. The first step is the generation of an evenly distributed

random location (r , r

, r ) within a circle of unity radius

) within a circle of unity radius

, where r

, where r and r

and r are evenly

distributed random numbers

are evenly

distributed random numbers  (-1, 1). The Gaussian distributed coordinates (x

(-1, 1). The Gaussian distributed coordinates (x , y

, y ) can then be calculated

using the Marsaglia equations

) can then be calculated

using the Marsaglia equations

|

(124) |

A sample Gaussian distributed nanodot is shown in Figure 3.21.

Figure 3.21:

Nanodot generated using Gaussian particle distribution. The vertical dimension has been scaled by 20 for better visualization.

(a) NCM nanodot generated using a Gaussian distribution of particles and (b) Diagonal cross-section of the nanodot from Figure 6.13a

|

![\includegraphics[width=0.481\linewidth]{chapter_process_modeling/figures/gaussian_dot.eps}](img481.png) |

![\includegraphics[width=0.481\linewidth]{chapter_process_modeling/figures/gaussian_dot2.eps}](img482.png) |

| (a) NCM Gaussian nanodot |

(b) Cross-section. |

|

The Gaussian distribution is well known; however from Figure 3.22, it is suggested that a Lorentzian distribution is a better fit to the

final shape of the desired nanostructure [84].

Figure 3.22:

(a) Comparison between the Gaussian distribution and the surface charge density and (b) comparison between the

Lorentzian distribution and the surface charge density.

|

![\includegraphics[width=0.481\linewidth]{chapter_process_modeling/figures/gauss_charge.eps}](img483.png) |

![\includegraphics[width=0.481\linewidth]{chapter_process_modeling/figures/lorentz_charge.eps}](img484.png) |

| (a) Gaussian distribution. |

(b) Lorentzian distribution. |

|

The implementation of the Gaussian distribution was performed successfully, while a similar

approach to the Lorentzian distribution was attempted without much success. Therefore,

in order to generate particles according to a Lorentzian distribution, a novel

technique for a particle distribution which follows the Lorentzian equation is developed.

The technique results in equations similar to the Marsaglia-Polar equations from (3.53).

- One-Dimensional Distribution

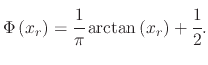

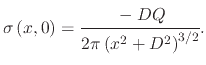

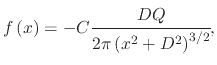

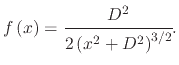

The normalized Probability Density Function (PDF) of the Lorentzian distribution is given by:

|

(125) |

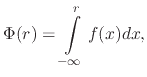

The Cumulative Probability Density (CPD) is found by integrating the PDF to obtain

|

(126) |

The quantile function of the Lorentzian distribution, required for particle generation, is

the inverse CPD

![$\displaystyle x_r=\Phi^{-1}\left(\xi\right)\equiv\tan\left[\pi\left(\xi-\cfrac{1}{2}\right)\right],$](img488.png) |

(127) |

where

is a uniformly distributed random number. Therefore, using (3.56), a random

particle can be generated to follow the Lorenzian distribution by first generating an evenly distributed value for

is a uniformly distributed random number. Therefore, using (3.56), a random

particle can be generated to follow the Lorenzian distribution by first generating an evenly distributed value for  .

.

- Two-Dimensional Distribution

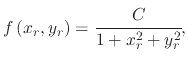

The same analysis shown for the one-dimensional Lorentzian distribution must be performed in order

to generate a two-dimensional Lorentzian quantile function. The two-dimensional Lorenzian distribution is required

when a three-dimensional nanodot needs to be simulated.

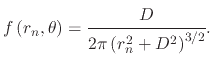

The PDF of the two-dimensional Lorentzian distribution can be represented as

|

(128) |

where  is the normalization constant. Using polar coordinates, where

is the normalization constant. Using polar coordinates, where

and

and

, it can easily be shown that

the PDF cannot be normalized in the entire real space

, it can easily be shown that

the PDF cannot be normalized in the entire real space  . We therefore must

normalize the equation to a desired maximum radius

. We therefore must

normalize the equation to a desired maximum radius  .

.

|

(129) |

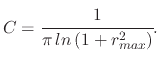

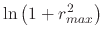

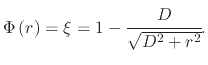

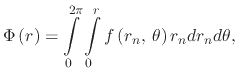

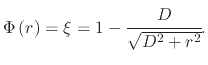

The normalization constant follows from the CPD, normalized to

|

(130) |

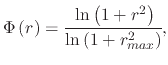

The CPD for the two-dimensional distribution, normalized to  can then be written as

can then be written as

|

(131) |

where

is treated as a

is treated as a  -dependent

constant

-dependent

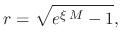

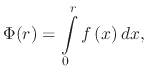

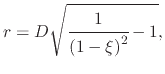

constant  . By inverting the CPD and solving for

. By inverting the CPD and solving for  the two-dimensional Lorentzian

quantile function is found, which is required for particle generation

the two-dimensional Lorentzian

quantile function is found, which is required for particle generation

|

(132) |

where

is a uniformly distributed random number. Using (3.61), a random

particle location can be generated in two-dimensional space to follow the Lorenzian distribution.

The generated location is a radial distance from the center of the distribution.

is a uniformly distributed random number. Using (3.61), a random

particle location can be generated in two-dimensional space to follow the Lorenzian distribution.

The generated location is a radial distance from the center of the distribution.

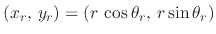

An evenly distributed angle  between 0 and 2

between 0 and 2 is generated and the final

particle position is given by

is generated and the final

particle position is given by

.

It can be observed that the choice of

.

It can be observed that the choice of  affects the height of the Lorentzian

distribution, thereby affecting the height of the desired nanodot. Therefore,

an additional contribution, dependent on

affects the height of the Lorentzian

distribution, thereby affecting the height of the desired nanodot. Therefore,

an additional contribution, dependent on  , is needed in the equation for the

height generated by each particle. This contribution is

, is needed in the equation for the

height generated by each particle. This contribution is

|

(133) |

The resulting nanodot cross section, shown in Figure 3.23 matches

the ideal one-dimensional Lorentzian distribution. This method allows the

generation of nanodots, such as the one shown in Figure 3.24,

which follow a Lorentzian distribution, as desired for the AFM oxidation simulator.

Figure 3.23:

Cross-sectional nanodot height generated using a Lorentzian distribution.

|

![\includegraphics[width=0.6\linewidth]{chapter_process_modeling/figures/Attempt2_2.eps}](img505.png) |

Figure 3.24:

The vertical dimension has been scaled by 20 for better visualization.

(a) NCM nanodot generated using a Lorentzian distribution of particles and (b) Diagonal

cross-section of the nanodot

from Figure 3.24a.

|

![\includegraphics[width=0.481\linewidth]{chapter_process_modeling/figures/lorentzian_dot.eps}](img506.png) |

![\includegraphics[width=0.481\linewidth]{chapter_process_modeling/figures/lorentzian_dot2.eps}](img507.png) |

| (a) NCM Lorentzian nanodot. |

(b) Cross-section. |

|

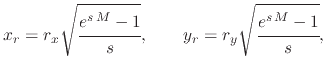

The expression for the quantile function in (3.61) suggests a potential

connection to the Marsaglia polar method. A Lorentzian distribution can be generated

using a similar procedure. The first step is, once again, the generation of an evenly distributed random

location in two dimensions

within a circle with radius

within a circle with radius

.

The Lorentzian distributed coordinates

.

The Lorentzian distributed coordinates

can then be expressed as:

can then be expressed as:

|

(134) |

where

.

.

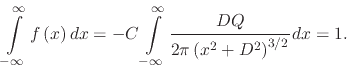

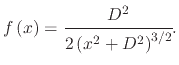

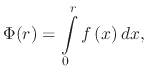

SCD charge density on the

silicon wafer is advantageous since a nanodot can then be generated which directly follows the applied electric field, a function

of the applied voltage at the AFM needle.

When performing nanodot oxidation simulations using an AFM for a two-dimensional model, a one-dimensional

particle distribution is required. The equation (3.37), for a SCD distribution of

a hemispherical needle tip can be re-written in a one-dimensional form:

|

(135) |

(3.64) can then be used to generate a one-dimensional PDF

|

(136) |

where  is the normalization constant.

is the normalization constant.  is found by integrating

is found by integrating

over the entire

simulation domain and equating it to unity:

over the entire

simulation domain and equating it to unity:

|

(137) |

By solving (3.66), the normalization constant  is found

is found

|

(138) |

which is then substituted into (3.65) to form the normalized PDF for a one-dimensional SCD distribution

|

(139) |

The next step is finding the CPD function, derived by integrating the normalized PDF,

|

(140) |

where  is the SCD distributed

radius. Because of the symmetry of the SCD distribution on either side of the charged

particle

is the SCD distributed

radius. Because of the symmetry of the SCD distribution on either side of the charged

particle  , generating a CPD distributed radius becomes easier, when

, generating a CPD distributed radius becomes easier, when

.

Therefore, we set

.

Therefore, we set

|

(141) |

leading to

|

(142) |

Setting  equal to an evenly distributed random number

equal to an evenly distributed random number

and inverting

(3.71) allows us to obtain the SCD quantile function required for

particle generation:

and inverting

(3.71) allows us to obtain the SCD quantile function required for

particle generation:

|

(143) |

Therefore, in order to generate particles obeying the SCD distribution along the silicon

wafer surface, each particle must be generated using (3.72), where  is an evenly

distributed random number,

is an evenly

distributed random number,

.

.

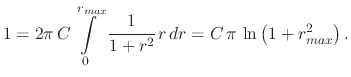

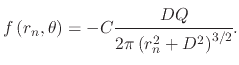

When working with a three-dimensional model for AFM oxidation of nanodots, a two-dimensional

particle distribution is required. The analysis is similar to the one-dimensional

model presented in the previous section. The derivation of the quantile

function is performed using polar coordinates for simplicity and for easier generation of a

final radial distribution of particles. For polar coordinates

it is important to note

that

it is important to note

that

, and

, and

. This was also discussed when deriving the Lorentzian distribution.

The two-dimensional PDF, in polar coordinates, derived from (3.37) is

. This was also discussed when deriving the Lorentzian distribution.

The two-dimensional PDF, in polar coordinates, derived from (3.37) is

|

(144) |

The normalization constant  is once again found by integrating the PDF over the entire simulation range and equating it to

one:

is once again found by integrating the PDF over the entire simulation range and equating it to

one:

|

(145) |

then the normalized two-dimensional PDF in polar coordinates becomes

|

(146) |

The CPD is found by integrating the normalized PDF over the simulation area. The angular component results in a value of 2 , while

the radial component is found by first finding the radius-dependent CPD

, while

the radial component is found by first finding the radius-dependent CPD

|

(147) |

which equates to

|

(148) |

The quantile function for the two-dimensional SCD distribution is found by inverting the CPD

function to obtain

|

(149) |

where  is an evenly distributed random number,

is an evenly distributed random number,

. The angular component of the distribution is obtained in the same

manner as the radial component for the Lorentzian distribution. An evenly distributed angle

. The angular component of the distribution is obtained in the same

manner as the radial component for the Lorentzian distribution. An evenly distributed angle  between 0 and

between 0 and  is found and the

final Cartesian location for each particle is given by

is found and the

final Cartesian location for each particle is given by

.

The normalized cross-section of a nanodot generated using this distribution is compared to

the normalized SCD from (3.64) in Figure 3.25.

.

The normalized cross-section of a nanodot generated using this distribution is compared to

the normalized SCD from (3.64) in Figure 3.25.

Figure 3.25:

Normalized effective nanodot cross section height and the normalized SCD function.

|

![\includegraphics[width=0.65\linewidth]{chapter_process_modeling/figures/cross-sect.eps}](img538.png) |

As previously mentioned, a rough needle tip must be modeled using a ring of charges at a given height above the silicon

surface. The SCD distribution is found using the method of image charges and summing the effects of each individual

charge which makes up the charged ring, resulting in the SCD distribution shown in (3.38).

The SCD in (3.38) does not allow for a straight-forward derivation

of a random distribution, such as the one shown in (3.72) and (3.78).

Therefore, the MC rejection technique, or the accept-reject algorithm must be applied, whereby a test point is generated on the entire

simulation domain using an even distribution,

. An additional

evenly distributed number between zero and

. An additional

evenly distributed number between zero and

from (3.39) is generated and, if this number is

below

from (3.39) is generated and, if this number is

below

, a particle is generated at

, a particle is generated at

.

Otherwise, the location

.

Otherwise, the location

is ignored and a new test point is generated.

This procedure is repeated until a sufficient number of particles is kept in order to generate

a nanodot topography.

is ignored and a new test point is generated.

This procedure is repeated until a sufficient number of particles is kept in order to generate

a nanodot topography.

Figure 3.26:

The effective diagonal cross-section height of a nanodot when using a rough AFM needle tip versus a hemispherical AFM needle tip.

|

![\includegraphics[width=\linewidth]{chapter_process_modeling/figures/Hemispherical.eps}](img543.png) |

It is evident that a blunt needle tip

will result in a blunt nanodot formation with a slight increase in lateral spreading.

The effective height of a nanodot when using a rough AFM needle tip versus a hemispherical

AFM needle tip is shown in Figure 3.26. It is visible that the height at the middle of

the nanodot is lower for a rough needle tip, as the electric field is spread laterally.

L. Filipovic: Topography Simulation of Novel Processing Techniques

![\includegraphics[width=\linewidth]{chapter_process_modeling/figures/AFM_distribution.eps}](img470.png)

![\includegraphics[width=0.9\linewidth]{chapter_oxidation_modeling/figures/flowchart.eps}](img471.png)

![]() , is

, is

![]() between 0 and 2

between 0 and 2![]() is generated and the final

particle position is given by

is generated and the final

particle position is given by

![]() .

It can be observed that the choice of

.

It can be observed that the choice of ![]() affects the height of the Lorentzian

distribution, thereby affecting the height of the desired nanodot. Therefore,

an additional contribution, dependent on

affects the height of the Lorentzian

distribution, thereby affecting the height of the desired nanodot. Therefore,

an additional contribution, dependent on ![]() , is needed in the equation for the

height generated by each particle. This contribution is

, is needed in the equation for the

height generated by each particle. This contribution is

![]() within a circle with radius

within a circle with radius

![]() .

The Lorentzian distributed coordinates

.

The Lorentzian distributed coordinates

![]() can then be expressed as:

can then be expressed as:

![]() it is important to note

that

it is important to note

that

![]() , and

, and

![]() . This was also discussed when deriving the Lorentzian distribution.

The two-dimensional PDF, in polar coordinates, derived from (3.37) is

. This was also discussed when deriving the Lorentzian distribution.

The two-dimensional PDF, in polar coordinates, derived from (3.37) is

![]() . An additional

evenly distributed number between zero and

. An additional

evenly distributed number between zero and

![]() from (3.39) is generated and, if this number is

below

from (3.39) is generated and, if this number is

below

![]() , a particle is generated at

, a particle is generated at

![]() .

Otherwise, the location

.

Otherwise, the location

![]() is ignored and a new test point is generated.

This procedure is repeated until a sufficient number of particles is kept in order to generate

a nanodot topography.

is ignored and a new test point is generated.

This procedure is repeated until a sufficient number of particles is kept in order to generate

a nanodot topography.

![\includegraphics[width=\linewidth]{chapter_process_modeling/figures/Hemispherical.eps}](img543.png)