. In [61] they presented a correction scheme for (4.3),

which is based on the determination of the accumulated degradation due to stress

after the delay time

. In [61] they presented a correction scheme for (4.3),

which is based on the determination of the accumulated degradation due to stress

after the delay time  as

as

Grasser et al. refined the approach of [6, 88] to obtain universality irrespective of

the amount of  . In [61] they presented a correction scheme for (4.3),

which is based on the determination of the accumulated degradation due to stress

after the delay time

. In [61] they presented a correction scheme for (4.3),

which is based on the determination of the accumulated degradation due to stress

after the delay time  as

as

| (4.4) |

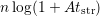

Here,  splits up into

splits up into  , the recoverable amount of degradation monitored

at

, the recoverable amount of degradation monitored

at  , and a permanent components

, and a permanent components  which is regarded as independent of

which is regarded as independent of

. In [29],

. In [29],  was supposed to follow a power-law of the form

was supposed to follow a power-law of the form

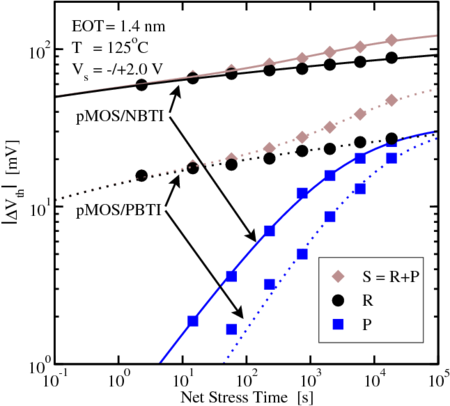

. In order to characterize the temperature and bias dependence of

the components of (4.4), plasma-nitrided-oxide (PNO) devices with an

effective oxide thickness (EOT) of

. In order to characterize the temperature and bias dependence of

the components of (4.4), plasma-nitrided-oxide (PNO) devices with an

effective oxide thickness (EOT) of  and

and  were characterized.

Therefore the OTF-method [17] and the fast-

were characterized.

Therefore the OTF-method [17] and the fast- -method developed by

[11] were used. The latter method is embedded into an eMSM-sequence

which is carried out with

-method developed by

[11] were used. The latter method is embedded into an eMSM-sequence

which is carried out with  stress/relaxation-subsequences, already

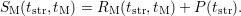

described in Chapter 2.1. A typical eMSM-measurement is shown in

Fig. 4.3.

stress/relaxation-subsequences, already

described in Chapter 2.1. A typical eMSM-measurement is shown in

Fig. 4.3.

is matched on the relaxation model (4.5)

with

is matched on the relaxation model (4.5)

with  parameters. It yields perfect universality over more than

parameters. It yields perfect universality over more than  decades in time (lines). Bottom Left: After subtracting the single

decades in time (lines). Bottom Left: After subtracting the single  of

each relaxation sequence (marked above), all data can be fit to a single line.

The universality of the relaxing component

of

each relaxation sequence (marked above), all data can be fit to a single line.

The universality of the relaxing component  is clearly visible. Bottom

Right: Without considering

is clearly visible. Bottom

Right: Without considering  , data at large stress times does not conform

to the universality.

, data at large stress times does not conform

to the universality.

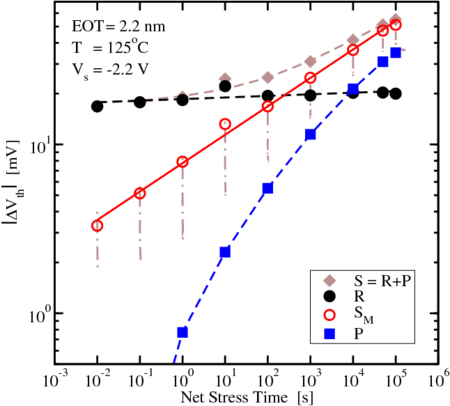

For the extraction of  and

and  , the yet unknown permanent contributions

of the single relaxation phases

, the yet unknown permanent contributions

of the single relaxation phases  have to be determined simultaneously. The

remaining non-permanent parts of the relaxation sequences are then fit to the

universal relaxation law (4.2). Altogether this yields a relaxation model with

have to be determined simultaneously. The

remaining non-permanent parts of the relaxation sequences are then fit to the

universal relaxation law (4.2). Altogether this yields a relaxation model with

parameters

parameters

and

and  are fit parameters for the universal recoverable component

are fit parameters for the universal recoverable component

, and the

, and the  with

with  denote the

denote the  relaxation sequences which

have to be optimized. The results of the optimization loop are then illustrated in

Fig. 4.4, clearly showing the existence of a permanent (or slowly relaxing)

component [30], when the recovery levels off. In contrast to

relaxation sequences which

have to be optimized. The results of the optimization loop are then illustrated in

Fig. 4.4, clearly showing the existence of a permanent (or slowly relaxing)

component [30], when the recovery levels off. In contrast to  , which can be

fitted by a power-law or

, which can be

fitted by a power-law or  ,

,  behaves like a power-law for

shorter stress times only. It clearly shows signs of saturation at longer stress

times, which is fundamental for lifetime extrapolation. Without considering such

a permanent component, universality is not given, like shown in Fig. 4.3 (bottom

left).

behaves like a power-law for

shorter stress times only. It clearly shows signs of saturation at longer stress

times, which is fundamental for lifetime extrapolation. Without considering such

a permanent component, universality is not given, like shown in Fig. 4.3 (bottom

left).

and

the extracted recoverable and permanent components

and

the extracted recoverable and permanent components  and

and  .

By back-extrapolating

.

By back-extrapolating  the “real” total degradation

the “real” total degradation

is obtained, consisting of

is obtained, consisting of  (compare to the true

degradation depicted left). The relaxation data in-between the stress

sequences is indicated by dash-dotted lines on a relative time scale

(compare to the true

degradation depicted left). The relaxation data in-between the stress

sequences is indicated by dash-dotted lines on a relative time scale

. The recoverable component

. The recoverable component  can be well fit by either a

power-law or

can be well fit by either a

power-law or  (used in the following) while

(used in the following) while  closely

follows

closely

follows  after [6].

after [6].

Moreover, it is of utmost importance to study wide relaxation periods, as the

data gained that way yields a much more reliable basis for modeling, compared

to other measurements done on commercial equipment: While Alam et al.

covered about  decades in time [85, 49], the widest recovery behavior observed

with commercial equipment so far accounted for

decades in time [85, 49], the widest recovery behavior observed

with commercial equipment so far accounted for  decades time [6, 66, 40].

Using their dedicated equipment Reisinger et al. [11] were able to measure BTI

relaxation periods of

decades time [6, 66, 40].

Using their dedicated equipment Reisinger et al. [11] were able to measure BTI

relaxation periods of  to

to  decades in time with the shortest available delay

time of

decades in time with the shortest available delay

time of  , cf. Fig. 4.3.

, cf. Fig. 4.3.

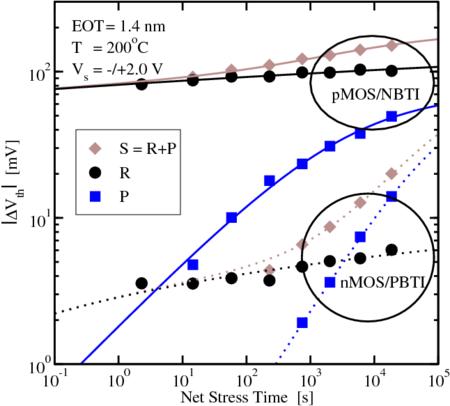

Applying the universality on various pMOS/nMOS-NBTI/PBTI-combinations yields different quantitative, but all in all consistent results. Surprisingly, this also applies to the negative shift of the threshold voltage they all have in common, for details refer to Fig. 4.5 and Fig. 4.6.

compared to the devices of Fig. 4.3 and Fig. 4.4

with

compared to the devices of Fig. 4.3 and Fig. 4.4

with  , a considerably larger

, a considerably larger  but a comparable

but a comparable  component.

The recoverable component during PBTI stress is qualitatively the same but

shifted by a factor of

component.

The recoverable component during PBTI stress is qualitatively the same but

shifted by a factor of  to smaller values, while the permanent component

is quite similar compared to NBTI.

to smaller values, while the permanent component

is quite similar compared to NBTI.

compared to the devices of Fig. 4.3

and Fig. 4.4 with

compared to the devices of Fig. 4.3

and Fig. 4.4 with  , a considerably larger

, a considerably larger  but a comparable

but a comparable

component. Comparison of pMOS/NBTI and nMOS/PBTI stress. The

recoverable component of the nMOS is very small (

component. Comparison of pMOS/NBTI and nMOS/PBTI stress. The

recoverable component of the nMOS is very small ( ). Hence, the

degradation is dominated by

). Hence, the

degradation is dominated by  from an early stage when comparing it to

pMOS.

from an early stage when comparing it to

pMOS.