The use of

in microelectronic devices is very convenient because

in microelectronic devices is very convenient because

builds a native oxide on top of the

builds a native oxide on top of the

surface following the oxidation reactions

surface following the oxidation reactions

where the

is built by

is built by

consumption from the surface. After the

first oxide layer is built, oxygen and water have to diffuse to the

consumption from the surface. After the

first oxide layer is built, oxygen and water have to diffuse to the

-

-

interface to grow new oxide.

With this type of oxidation, very thin layers of

interface to grow new oxide.

With this type of oxidation, very thin layers of

can be deposited.

However, thick oxide layers take a long time to build with this process

technique and use a certain amount of

can be deposited.

However, thick oxide layers take a long time to build with this process

technique and use a certain amount of

as a source of the oxide layer.

as a source of the oxide layer.

Therefore, another technique has been introduced which transports all its

sources via a carrier gas to the reactor where they react at the wafer surface,

using the wafer surface as a catalytic material.

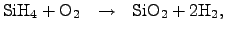

A deposition process using silane

has been commonly established, which

follows the reaction equation

has been commonly established, which

follows the reaction equation

|

(2.140) |

where the

reacts with oxygen at the hot wafer surface and

reacts with oxygen at the hot wafer surface and

is built together with

is built together with

. A optimal temperature for this reaction

process is in the region of 1300 K [25].

The by-products from (2.138)-(2.140) are able to

diffuse through the oxide to the plain

. A optimal temperature for this reaction

process is in the region of 1300 K [25].

The by-products from (2.138)-(2.140) are able to

diffuse through the oxide to the plain

and react with

and react with

as oxygen or

as water according to (2.138) and (2.139).

This diffusion of oxygen and water can be controlled by regulating the

temperature of the reaction process (2.140). However, despite of the

regulative measures, some of the

as oxygen or

as water according to (2.138) and (2.139).

This diffusion of oxygen and water can be controlled by regulating the

temperature of the reaction process (2.140). However, despite of the

regulative measures, some of the

is alway consumed.

In addition, a considerable concentration of

is alway consumed.

In addition, a considerable concentration of

is built during the

deposition of

is built during the

deposition of

and has to be taken into account for reliability issues

during the further processing and the device operations [25,127].

and has to be taken into account for reliability issues

during the further processing and the device operations [25,127].

The previously presented methods have shown how a

layer can be deposited by

using

layer can be deposited by

using

from the target material (wafer). However, if

from the target material (wafer). However, if

consumption

is not allowed at the surface, a more complex deposition method is required. A

possible alternative, which provides that requirement is TEOS

(Tetra-ethoxy-silane,

consumption

is not allowed at the surface, a more complex deposition method is required. A

possible alternative, which provides that requirement is TEOS

(Tetra-ethoxy-silane,

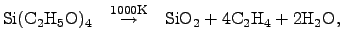

). The deposition of

). The deposition of

with TEOS uses a

pyrolytic chemical reaction at a hot wafer surface in a LPCVD process

(low pressure chemical vapor deposition)

and follows the chemical reaction [25,127]

with TEOS uses a

pyrolytic chemical reaction at a hot wafer surface in a LPCVD process

(low pressure chemical vapor deposition)

and follows the chemical reaction [25,127]

|

(2.141) |

where the semiconductor device structures on the wafer are heated at a

temperature of approximately  K. The reactant TEOS is transported

from a material reservoir to the reactor via a carrier gas typically consisting

of

K. The reactant TEOS is transported

from a material reservoir to the reactor via a carrier gas typically consisting

of

and

and

.

At the hot surface of the wafer, the pyrolytic dissociation reaction (2.141)

takes place. Typical

.

At the hot surface of the wafer, the pyrolytic dissociation reaction (2.141)

takes place. Typical

growth rates at these environment conditions are

100 Å/min [25] up to 1000 Å/min [127]. The growth

rate can be controlled within a certain range by varying the temperature,

pressure, and the TEOS concentration in the carrier gas.

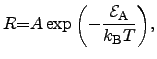

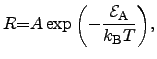

Typically, the deposition reactions follow an ARRHENIUS2.38law [176]

growth rates at these environment conditions are

100 Å/min [25] up to 1000 Å/min [127]. The growth

rate can be controlled within a certain range by varying the temperature,

pressure, and the TEOS concentration in the carrier gas.

Typically, the deposition reactions follow an ARRHENIUS2.38law [176]

|

(2.142) |

where the reaction rate  depends exponentially on the activation energy

depends exponentially on the activation energy

. The proportionality constant

. The proportionality constant  depends on the surface shape and the

chemical reaction which takes place and must therefore be determined separately

for each different deposition type.

The proportionality constant

depends on the surface shape and the

chemical reaction which takes place and must therefore be determined separately

for each different deposition type.

The proportionality constant  often depends on the temperature through a

square-root law [127]

often depends on the temperature through a

square-root law [127]

|

(2.143) |

Stefan Holzer

2007-11-19

![]() in microelectronic devices is very convenient because

in microelectronic devices is very convenient because

![]() builds a native oxide on top of the

builds a native oxide on top of the

![]() surface following the oxidation reactions

surface following the oxidation reactions

![]() has been commonly established, which

follows the reaction equation

has been commonly established, which

follows the reaction equation

![]() layer can be deposited by

using

layer can be deposited by

using

![]() from the target material (wafer). However, if

from the target material (wafer). However, if

![]() consumption

is not allowed at the surface, a more complex deposition method is required. A

possible alternative, which provides that requirement is TEOS

(Tetra-ethoxy-silane,

consumption

is not allowed at the surface, a more complex deposition method is required. A

possible alternative, which provides that requirement is TEOS

(Tetra-ethoxy-silane,

![]() ). The deposition of

). The deposition of

![]() with TEOS uses a

pyrolytic chemical reaction at a hot wafer surface in a LPCVD process

(low pressure chemical vapor deposition)

and follows the chemical reaction [25,127]

with TEOS uses a

pyrolytic chemical reaction at a hot wafer surface in a LPCVD process

(low pressure chemical vapor deposition)

and follows the chemical reaction [25,127]