In the last two decades thermoelectric devices received significant attention, mainly due to the introduction of nanostructures with promising thermoelectric properties. One of the first approaches was the phonon-glass-electron-crystal (PGEC) approach. This means that one has to design nanostructured materials which simultaneously decrease the thermal conductivity and keep the carrier mobility unchanged [8]. Another approach, suggested by Dresselhaus [9,10], is related to the shape of the density of states (DOS) of low-dimensional materials. It has been argued that sharp features in the ![]() function of 1D and 2D conductors can result in a higher Seebeck coefficient and higher thermoelectric performance. As shown in Fig. 1.7, the density of states of 1D nanostructures has sharp features that could increase the Seebeck coefficient. In a different work, it was pointed out that the best thermoelectric material would be the one with a delta-function shape

function of 1D and 2D conductors can result in a higher Seebeck coefficient and higher thermoelectric performance. As shown in Fig. 1.7, the density of states of 1D nanostructures has sharp features that could increase the Seebeck coefficient. In a different work, it was pointed out that the best thermoelectric material would be the one with a delta-function shape ![]() [11]. This ideal thermoelectric material, however, benefits from the zero value for the electrical carrier contribution to the thermal conductivity, which minimizes the dominator of

[11]. This ideal thermoelectric material, however, benefits from the zero value for the electrical carrier contribution to the thermal conductivity, which minimizes the dominator of ![]() [11,12]. Nanostructures could in addition offer several degrees of freedom for parameter optimization, i.e. geometrical parameters such the diameter of nanowires and thickness of thin-layers, and provide the possibility of independently designing the quantities that control

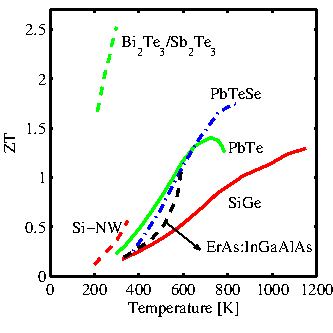

[11,12]. Nanostructures could in addition offer several degrees of freedom for parameter optimization, i.e. geometrical parameters such the diameter of nanowires and thickness of thin-layers, and provide the possibility of independently designing the quantities that control ![]() . The advancements in lithography and nanofabrication have recently led to the realization of breakthrough experiments on nanostructured thermoelectric devices that demonstrated enhanced performance, sometimes even up to 2 orders of magnitude higher than the performance of corresponding bulk material, as shown in Fig. 1.8.

. The advancements in lithography and nanofabrication have recently led to the realization of breakthrough experiments on nanostructured thermoelectric devices that demonstrated enhanced performance, sometimes even up to 2 orders of magnitude higher than the performance of corresponding bulk material, as shown in Fig. 1.8.

These experimental (and theoretical) studies utilize several forms of nanostructures,

such as bulk materials with nanocomposites, in-plane and out-plane transport superlattices,

nanowires and nanoribbons, and 1D supperlattices. As mentioned in Sec. 1.3, one of the first efforts to improve ![]() of bulk materials was alloying

of bulk materials was alloying

![]() [13,3] to decrease the lattice thermal conductivity, without significant

reduction in the electrical conductivity. Similar approaches have been recently followed by introducing ErAs nanoparticles of

[13,3] to decrease the lattice thermal conductivity, without significant

reduction in the electrical conductivity. Similar approaches have been recently followed by introducing ErAs nanoparticles of

![]() in diameter in InGaAs/AlAs structures [14,15]. These nanopariticles effectively behave as scattering centers for phonons. In addition, they provide charge carriers that improve the electrical conductivity.

in diameter in InGaAs/AlAs structures [14,15]. These nanopariticles effectively behave as scattering centers for phonons. In addition, they provide charge carriers that improve the electrical conductivity.

|

Further improvement can be achieved in low dimensional materials. 2D supperlattices have been studied for providing simultaneous enhancement of the thermoelectric

power factor, and reduction of thermal conductivity [16,4]. In these structures, the power factor could increase due to the quantum confinement, strain engineering, and the sharp features of the 2D density of states. In addition, various scattering mechanisms such as boundary scattering, interface scattering, and defects scattering decrease the thermal conductivity. These mechanisms can even be stronger in 1D structures such as nanowires and nanoribons, as their ratio of boundary surface to volume is higher. To date, several studies have been performed on silicon nanowires [17], Si/Ge superlattice nanowires [18], and graphene nanoribbons [19]. However, the record high ![]() of about

of about ![]() was experimentally achieved for

was experimentally achieved for ![]() -type

-type

![]() superlattices (see Fig. 1.8) [16], which is composed of the best bulk thermoelectric materials.

superlattices (see Fig. 1.8) [16], which is composed of the best bulk thermoelectric materials.