Next: 2.5 Fabrication

Up: 2. The Processing Chain

Previous: 2.3 Layout

Subsections

2.4 Mask Generation

A fundamental requirement for almost all useful semiconductor devices is the

definition of patterned elements. The main stream technology choice for

patterning has been optical lithography. Up to the early 70's lithography was

done as a contact printing process in which blue or near UV

light was passed through a photo mask directly onto a photo resist coated

semiconductor substrate [30].This shadow imaging process has been

described in many research publications and

handbooks [31], [32].

Beginning in the early 80's a new class of projection exposure tools, known as

steppers, was introduced [33]. For the first time the pattern

definition imaging on the semiconductor wafers was performed one chip at a

time in a step-and-repeat fashion. Most stepper systems employed a reduction

projection lens to ease the fabrication difficulty of the photo mask and to

improve the overall precision and accuracy of the overlay of patterns on the wafer.

Even more recently a combination of the earlier scanning approach with the

step-and-repeat approach was created [34]. The step-and-scan approach has spread

rapidly throughout the lithography tool industry, and is used for critical

layers (like gate, metallization and contact layers) at the 250nm node and

below [35].

Until the mid 90's all optical photo masks have been chrome on glass (called

COG-photo masks) [36], also called binary photo masks. Starting from the 350nm node

significant innovations in binary masks such as OPC (optical proximity correction) [37] and

AAPSM (alternating aperture phase shift masks) [38] were introduced which improved

the resolution capability of binary photo masks. A second approach besides the

binary photo masks then emerged as EAPSM (embedded attenuated phase shift

masks) [39] also called HTM (half tone masks).

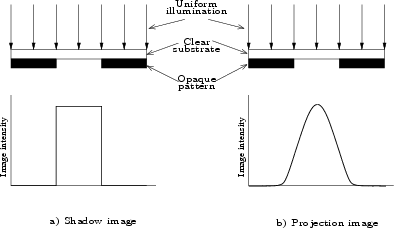

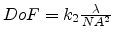

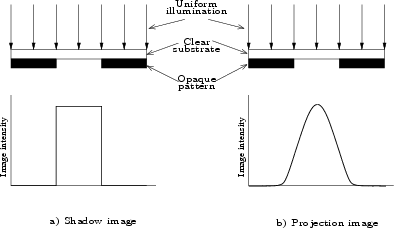

Lithography is based on replicating the pattern on a photo mask into

resist covered wafers. In an ideal case without degradation in the

imaging process, a simple copy of the mask pattern would result, as shown in

Figure 2.4 a.

Figure 2.4:

Basic imaging

characteristics (a) Ideal shadow imaging; (b) Diffraction-broadened

projection imaging

|

However, in a projection process the imaging is always subject to

degradation from diffraction and from imperfections in the projection

system. An example of the image from a diffraction-limited projection system

is shown in Figure 2.4 b.

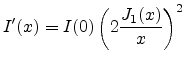

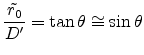

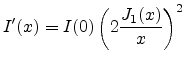

The spreading of the image profile results from the wave nature of light, and

it is this property that limits the resolution capability of

optical imaging systems. In an imaging lens system with a circular aperture of

radius

and imaging distance

and imaging distance  , the image intensity resulting from a point

source can be described by an expression containing a first order

BESSEL function,

, the image intensity resulting from a point

source can be described by an expression containing a first order

BESSEL function,

|

(2.1) |

where

and

and  is the distance in

the image plane from the geometrical image point.

is the distance in

the image plane from the geometrical image point.  is the wavelength

of the monochromatic light source. A detailed deduction of this

expression is given in Appendix E.2. The fraction

is the wavelength

of the monochromatic light source. A detailed deduction of this

expression is given in Appendix E.2. The fraction

given by

given by

for for |

(2.2) |

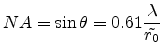

equals the numerical aperture  defined by

defined by

|

(2.3) |

with n as the refractive index of the medium behind the aperture or lens.

Therefore the expression for  can be further simplified to

can be further simplified to

.

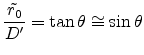

For air as medium (

.

For air as medium (

) a simplified description of

) a simplified description of  is given in

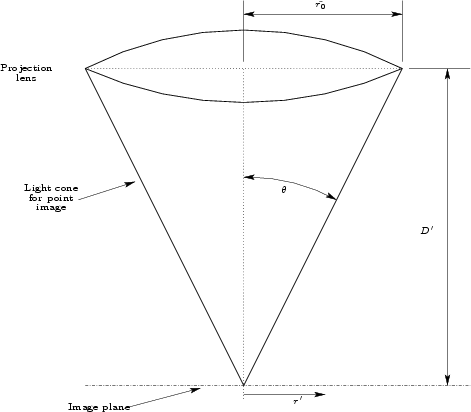

Figure 2.5 as

is given in

Figure 2.5 as

Figure 2.5:

Geometric

situation in simple projection optical system

|

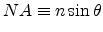

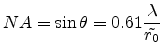

This light intensity distribution is known as the AIRY pattern, after

G.B. AIRY who first derived it in 1835 [40]. In addition to the

general shape of the curve, shown in Figure 2.6, the first zero value

is of interest. At about

occurs a intensity minimum and an

intensity maximum at

occurs a intensity minimum and an

intensity maximum at

.

.

Figure 2.6:

Light

intensity distribution from a point source projected through a circular

imaging lens. The variable x on the horizontal axis is defined in the text

|

|

Resolution is defined as the ability to distinguish components of an

object or a group of objects. The resolution capability of astronomical

telescopes was studied in detail by LORD RAYLEIGH in the 19th

century [41]. He defined the limit of resolution for a telescope

as the angular separation between two stars when the peak of the

AIRY intensity pattern from one star coincided with the first

minimum of the AIRY intensity pattern for the other star.

This leads to the well-known RAYLEIGH condition for angular

resolution

|

(2.4) |

where

is again the radius of the imaging objective aperture.

A sketch of the RAYLEIGH resolution condition is shown in

Figure 2.7. Note that the intensity at the midpoint between

the image peaks is reduced to about 78% of the peak intensity, which provides

discernible separation, but not with high contrast between the bright and dark

regions.

is again the radius of the imaging objective aperture.

A sketch of the RAYLEIGH resolution condition is shown in

Figure 2.7. Note that the intensity at the midpoint between

the image peaks is reduced to about 78% of the peak intensity, which provides

discernible separation, but not with high contrast between the bright and dark

regions.

Figure 2.7:

RAYLEIGH criterion for resolution of two point images in (a)

1D and (b) 2D. Scale is the same as in Figure 2.6

|

|

While the analogy of astronomical imaging to photo lithography is not

completely quantitative, some key observations can be made. There is a limit

to resolution for any given optical projection system, and it is not possible

to resolve arbitrarily small or closely spaced features. It is also apparent

that the resolution can be improved by using a smaller wavelength of the

exposure light, and the resolution can be improved by making the projection

system aperture larger.

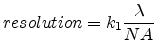

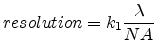

In practical lithography the RAYLEIGH condition is typically restructured into

the ``RAYLEIGH equation''

|

(2.5) |

where  is the numerical aperture of the projection system and

is the numerical aperture of the projection system and  is a

constant in the order of 0.4-0.8. There is no rigorous optical definition for

the constant

is a

constant in the order of 0.4-0.8. There is no rigorous optical definition for

the constant  , and it is generally used as a qualitative descriptor of

the overall lithography process capability. More details on the RAYLEIGH

equation are given in Table 2.1. Table 2.2

shows the numeric aperture, the resolution, and the depth of focus for the

most important wavelengths in lithography.

, and it is generally used as a qualitative descriptor of

the overall lithography process capability. More details on the RAYLEIGH

equation are given in Table 2.1. Table 2.2

shows the numeric aperture, the resolution, and the depth of focus for the

most important wavelengths in lithography.

Table 2.1:

Definitions for important

wavelength nodes in lithography

| Definitions |

|

|---|

(g-line) (g-line) |

436 nm |

(i-line) (i-line) |

365 nm |

(KrF) (KrF) |

248 nm |

(ArF) (ArF) |

193 nm |

( ( ) ) |

157 nm |

| Resolution |

|

|---|

| RAYLEIGH Resolution |

|

| Traditional |

|

| Advanced |

|

| Depth of Focus |

|

|---|

| RAYLEIGH Depth of Focus |

|

| Traditional |

|

|

This common description of resolution capability is closely related to the

AIRY pattern described above. In particular, the first minimum of

the AIRY pattern occurs at about

, and the

first maximum occurs at

, and the

first maximum occurs at

. The qualitative agreement

with the usual range of

. The qualitative agreement

with the usual range of  is apparent.

is apparent.

High performance optical projection imaging for lithography is strongly

impacted by diffraction effects as noted in several previous sections. One

result of this behavior is that individual pattern features do not image

independently, but rather they interact with neighboring pattern features. A

detailed analysis of the projection imaging process, for example, the analysis

described in the paper by Hopkins [42], considers contributions

from every portion of the reticle object and every portion of the projection

optics in determining the exact image at the wafer plane. A simple heuristic

argument considers the extended diffraction structure of the AIRY

function comprising of the additional local maxima in the intensity

distribution. Overlap of the diffraction peaks with adjacent pattern features

leads to increased or decreased exposure intensity at any point in the image,

compared to a purely geometrical image model.

Next: 2.5 Fabrication

Up: 2. The Processing Chain

Previous: 2.3 Layout

R. Minixhofer: Integrating Technology Simulation

into the Semiconductor Manufacturing Environment

![]() and imaging distance

and imaging distance ![]() , the image intensity resulting from a point

source can be described by an expression containing a first order

BESSEL function,

, the image intensity resulting from a point

source can be described by an expression containing a first order

BESSEL function,

for

for![]() occurs a intensity minimum and an

intensity maximum at

occurs a intensity minimum and an

intensity maximum at

![]() .

.

![\includegraphics[origin=cc,height=0.8\textwidth,clip=true]{figures/airy_pattern.rot.ps}](img62.png)

![]() , and the

first maximum occurs at

, and the

first maximum occurs at

![]() . The qualitative agreement

with the usual range of

. The qualitative agreement

with the usual range of ![]() is apparent.

is apparent.