Next: 5.6.2 Simulation Approach

Up: 5.6 Effect of Microstructure

Previous: 5.6 Effect of Microstructure

5.6.1 Microstructure Generation

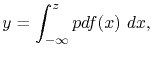

In order to include the grain distribution into the numerical simulations, a microstructure generation tool has been developed. Given a specific interconnect structure and providing the tool with a median grain size,  , and corresponding standard deviation,

, and corresponding standard deviation,  , it generates a lognormal distribution of grain sizes according to

, it generates a lognormal distribution of grain sizes according to

![$\displaystyle pdf(x) = \frac{1}{x\sigma\sqrt{2\pi}}\exp\left[-\frac{(\ln x-\ln x_0)^2}{2\sigma^2}\right].$](img731.png) |

(5.12) |

The angles between the grain boundaries' planes and the line surface at the top follow a normal distribution,

![$\displaystyle pdf(x) = \frac{1}{\sigma\sqrt{2\pi}}\exp\left[-\frac{(x-x_0)^2}{2\sigma^2}\right],$](img732.png) |

(5.13) |

where

is the median value of the angles.

Taking a radom number,

is the median value of the angles.

Taking a radom number,

![$ y \in [0,1]$](img734.png) , uniformly distributed, the grain sizes and grain boundary angles are determined by calculating

, uniformly distributed, the grain sizes and grain boundary angles are determined by calculating  , so that the inverse relation,

, so that the inverse relation,

|

(5.14) |

holds.

Once the grain sizes and angles are determined, the interconnect line is cut along its length by the planes which form the grain boundaries.

A typical microstructure generated by such a procedure is shown in Figure 5.35.

In this way, the microstructure generation tool yields a simple bamboo-like line.

Figure 5.35:

Typical microstructure generated from the procedure described above. The grain sizes follow a lognormal distribution, and the angles of the grain boundaries in relation to the top line surface follow a normal distribution.

|

|

Next: 5.6.2 Simulation Approach

Up: 5.6 Effect of Microstructure

Previous: 5.6 Effect of Microstructure

R. L. de Orio: Electromigration Modeling and Simulation

![]() , and corresponding standard deviation,

, and corresponding standard deviation, ![]() , it generates a lognormal distribution of grain sizes according to

, it generates a lognormal distribution of grain sizes according to

![\includegraphics[width=0.85\linewidth]{chapter_applications/Figures/gb_struct.eps}](img736.png)