2.3.1 Yield

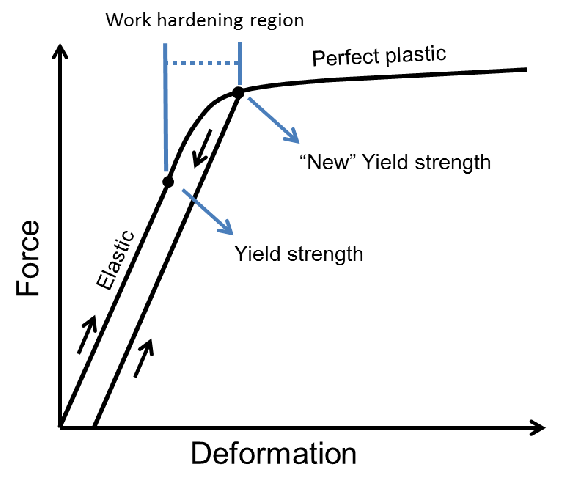

Yield is the name given to the point in the stress-strain curve where the material’s response

to an applied force switches from an elastic to an inelastic behavior [39]. A body unloaded

under a plastic regime keeps some strain (permanent deformations). Thus, a future loading

starts with an offset and the elastic regime is retained until the prior unload point is

reached, as sketched in Fig. 2.10. This means that the yield point shifts accordingly to the

load history of the material. Moreover, the yield strength increases and the material

becomes less prone to plastic deformations. This phenomenon is known as hardening. It is

behind the manufacturing of several engineering products, such as the creation of blades.

When a smith hits the metal, hardening takes place and it becomes tougher to deform

the metal permanently in any subsequent load, especially during the use of the

blade.