|

|

||||

BiographyLuiz Felipe Aguinsky was born in 1990 in Porto Alegre, Brazil. He received his Bachelor's degree in Physics from the Federal University of Rio Grande do Sul (BSc, 2013). Subsequently, he studied Simulation Sciences at RWTH Aachen University (MSc, 2018), having written the Master's thesis at the German Aerospace Center. After finishing his studies he joined the Institute for Microelectronics in March 2018, where he is currently working on his doctoral degree. He is researching high performance numerical approaches for Technology CAD within the scope of the Christian Doppler Laboratory for High Performance TCAD. |

|||||

Non-Ideal Conformality in Thermal Atomic Layer Deposition of Oxides

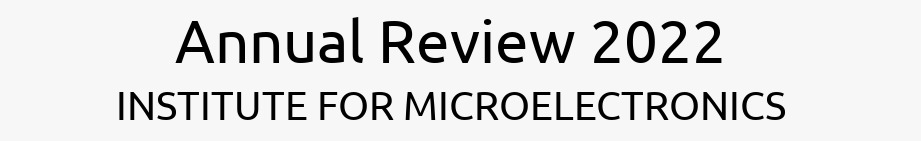

Atomic layer deposition (ALD) is a thin film deposition technique with multiple applications in the semiconductor industry. This technique enables excellent control over conformality and film thickness by dividing the growth process into self-limiting steps, which repeat in cycles. For oxides, the deposition is commonly split into a half-reaction from a metal-organic compound, e.g., trimethylaluminum (TMA) for the deposition of Al2O3, followed by a complementary step using ozone or H2O for thermal ALD, or O2 plasma. The possible reaction pathways for the H2O step after TMA coating are represented in Fig. 1.

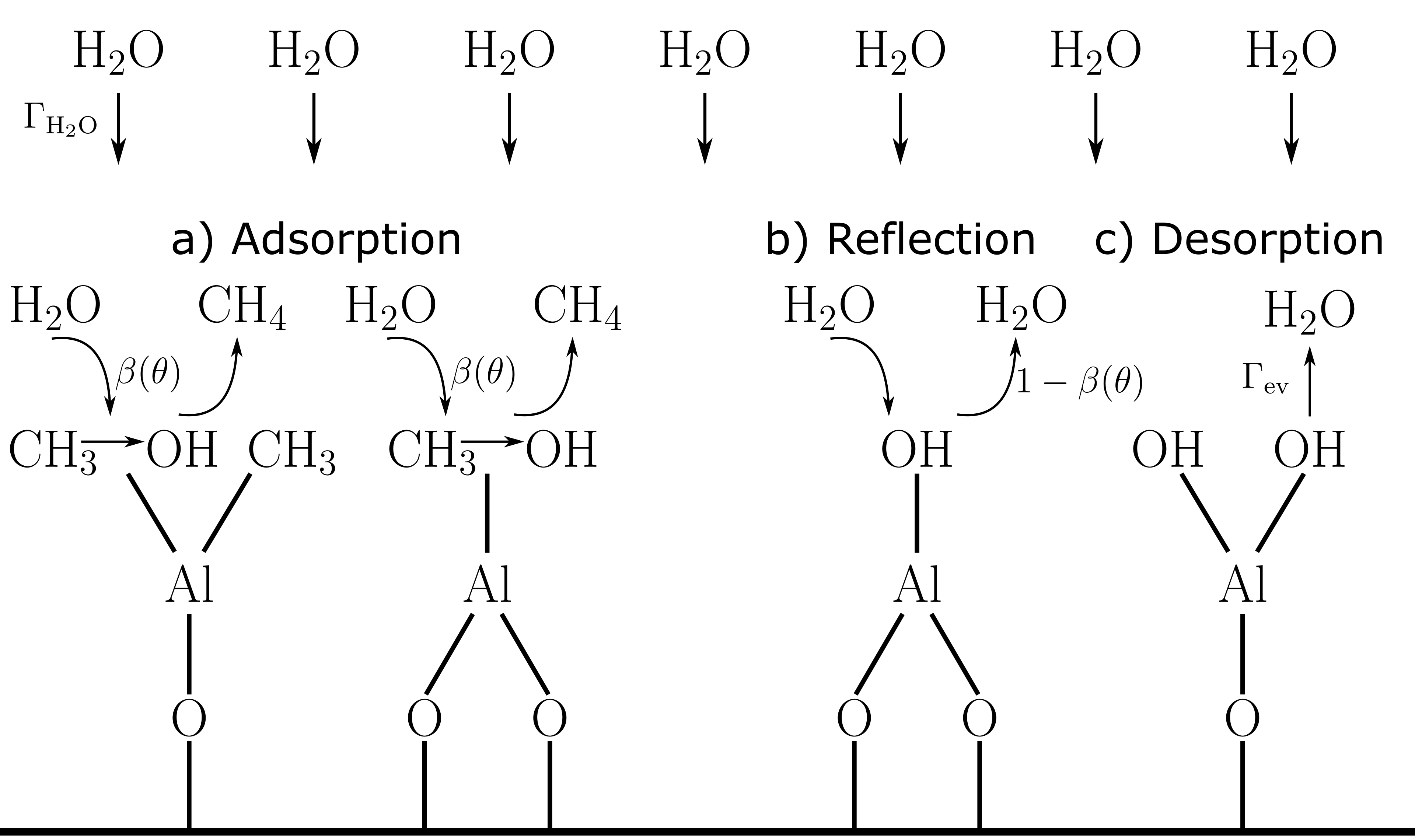

The thermal ALD of oxides such as Al2O3 and HfO2 are fundamentally important scientific processes that have also found application in semiconductor fabrication. For example, they have been used in the processing of high-κ capacitor films for DRAM and dielectric stacks for three-dimensional (3D) NAND. These structures offer additional processing challenges, as they involve high aspect ratios (AR). High AR structures test the limits of the conformal coating characteristics of ALD, as illustrated in Fig. 2, since the reactant transport is impeded. Thus, they require careful modeling to optimize their fabrication.

We address this problem by developing a one-dimensional (1D) reactive transport model for thermal ALD in high AR structures based on a first-order reversible Langmuir surface model and Knudsen diffusion. It involves a single particle — that is, it assumes one of the involved species is the limiting factor, and the complementary reactant has a sufficiently higher dose. This model has been successfully integrated in topography simulation tools to directly evaluate thickness profiles, thus enabling combination with other semiconductor processing steps and process-aware simulation of the device operation.

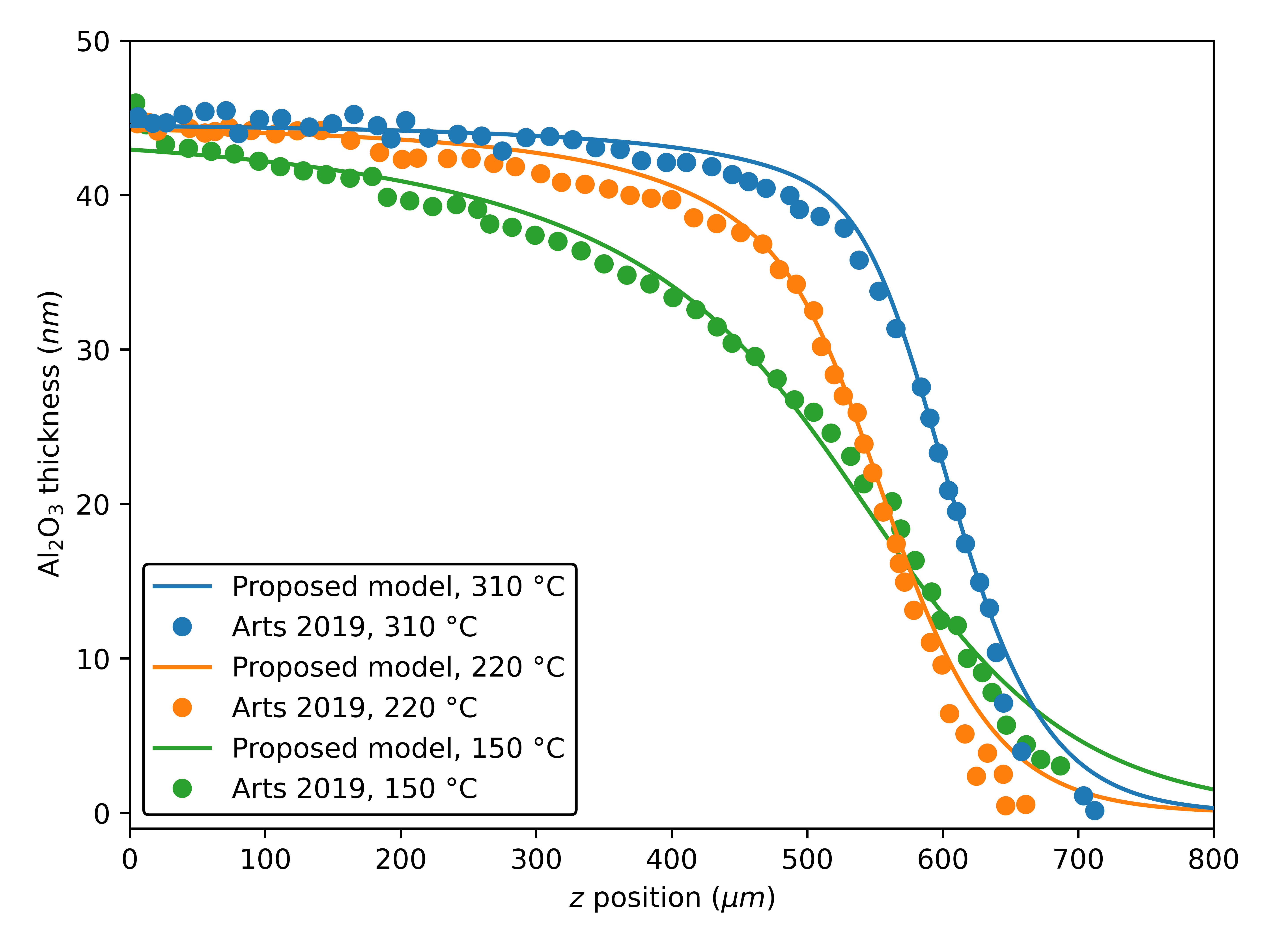

We calibrate this model to experimentally reported thickness profiles of Al2O3 from TMA and H2 after 400 ALD cycles at three substrate temperatures (150 °C, 220 °C, and 310 °C) in the H2O-limited regime. The model parameters — namely, the clean surface sticking coefficient and the evaporation flux — are calibrated individually for each temperature. The results of these calibrated simulations are presented in Fig. 3 and show good agreement. We highlight that the maximum thickness varies with temperature, which is a strong indicator that reversible kinetics (i.e., the presence of an evaporation flux depending on temperature) plays a fundamental role.

Fig. 1: Possible reaction pathways during the H2O step of ALD of Al2O3.

Fig. 2: Illustration of ALD process in a high aspect ratio trench showing non-ideal conformality.

Fig. 3: Comparison of simulated thickness profiles to experimental measurements reported by Arts et al., J. Vac. Sci. Technol. A 37, 030908 (2019).