|

|

||||

BiographyMarkus was born 1996 in Mistelbach, Austria. He received his bachelor degree in Technical Physics in 2019 from TU Wien and his master degree in Physical Energy and Measurement Engineering in 2023 carried out at the Institute of Applied Physics from TU Wien. After working for a year as a Requirements Engineer at Bosch, he began his PhD at the Institute for Microelectronics (IUE) in May 2024. His research focuses on developing measurement tools to characterize the performance and reliability of integrated devices and circuits. |

|||||

Developing Precise Measurement Tools for Semiconductor Reliability Studies

Random Telegraph Noise (RTN) and Bias Temperature Instability (BTI) are two of the most critical phenomena affecting the reliability of semiconductor devices. These effects arise primarily due to charge trapping in oxide defects within the device structure. At the Institute for Microelectronics (IUE), the focus is typically on the modeling and characterization of Field-Effect Transistors (FETs), where such degradation mechanisms are particularly significant.

To experimentally characterize these devices - commonly referred to as Devices Under Test (DUTs) - custom measurement equipment is developed with a strong emphasis on flexibility and modularity. This adaptability is especially important in both academic and industrial environments, where test conditions often vary based on device type and application.

The standard methodology for such characterization is the Measure-Stress-Measure (MSM) cycle. During this cycle, an initial measurement is performed by recording the drain current versus gate voltage (ID-VG curve). The device is then subjected to a defined stress voltage at the gate, which induces charge trapping in the oxide layer. Following this stress phase, a second ID-VG curve is measured. The resulting hysteresis - i.e., a shift in threshold voltage - indicates that a higher gate voltage is required to achieve the same drain current, due to trapped charges.

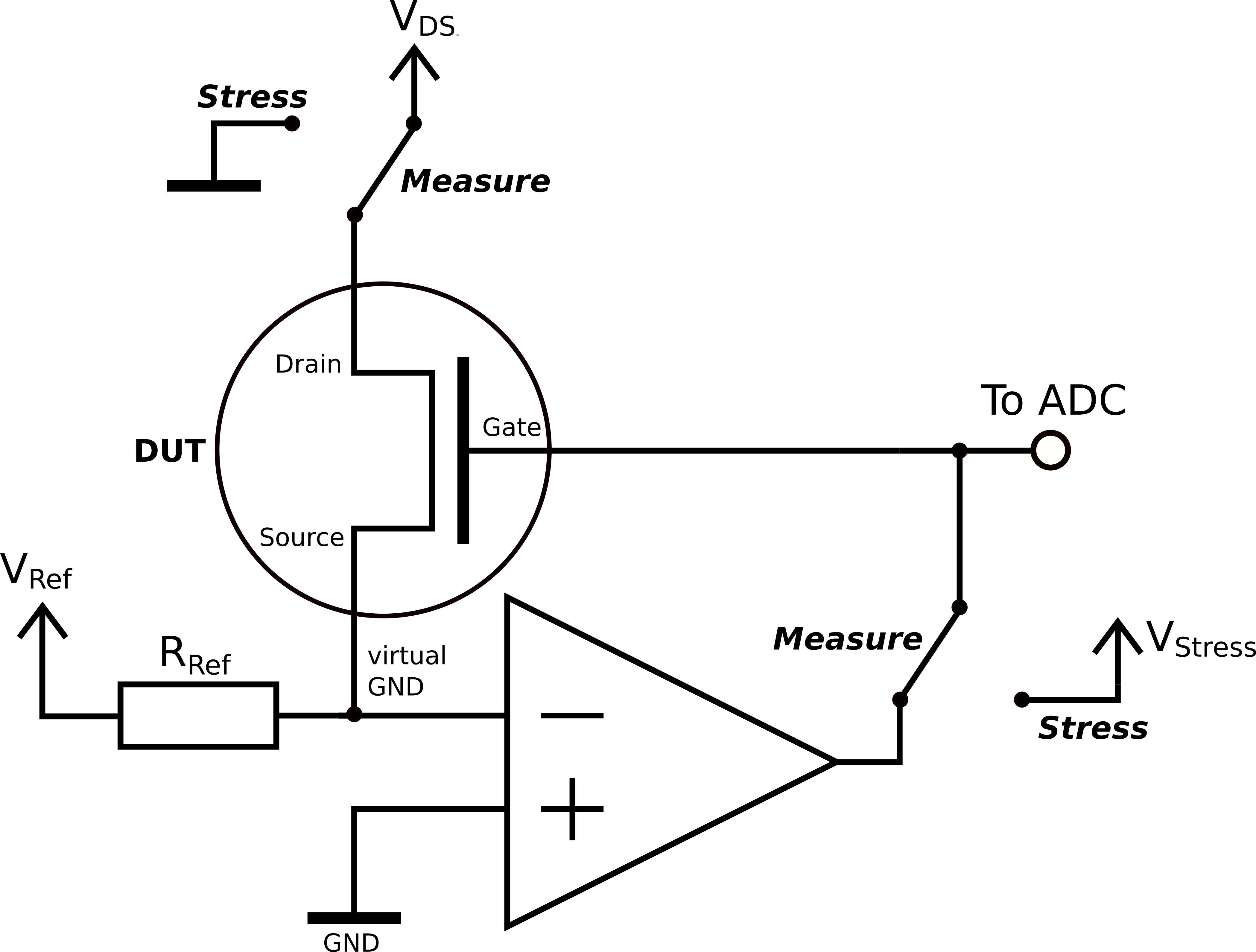

A different approach introduced in this research enables significantly faster detection of threshold voltage shifts by employing an alternative measurement setup. Unlike conventional systems that rely primarily on Transimpedance Amplifiers (TIAs), this new design directly measures the threshold voltage shift of the DUT, as illustrated in the Figure below.

This method allows for voltage shift measurements as fast as 1 microsecond - approximately 1000 times faster than existing equipment. Alongside the development of new circuits, ongoing work also focuses on improving current hardware in terms of speed, reliability, signal-to-noise ratio (SNR), and adaptability for diverse reliability testing needs.

Fig. 1: Simplified "Fast Vth" Circuit configuration