![\includegraphics[width=8cm]{ex0/geo3.eps}](img41.png)

|

In the following the influence of two different grid refining methods will be compared. The first method refines the grid by a global unstructured increase of grid points. This is done by down-scaling the maximum grid element area. This approach will be compared to a more sophisticated point placement algorithm which, as will be shown, also achieves more accurate results.

In Figure 1.1 a quarter of the cross-section of a coaxial capacitor is shown.

The electrode areas

![]() and

and

![]() are biased at 0 V and 1 V, respectively. The whole capacitor area

are biased at 0 V and 1 V, respectively. The whole capacitor area ![]() is filled by an insulator with constant permittivity

is filled by an insulator with constant permittivity

![]() .

.

Because of the axial symmetry of the device, this simulation could be performed in one dimension. However, to compare the influence of the grid adaption methods, the simulation is performed in two dimensions. This artificial example is chosen, because the analytical solution of this problem can be easily found and can be used to calculate the error of the two grid adaption methods.

For the analytical and numerical evaluation of this problem, the Laplace equation [22]

| (1.1) |

| (1.2) | |

| (1.3) |

| (1.4) |

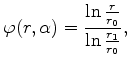

For this simple structure, an analytical solution can be found and the electrostatic potential results to

|

(1.5) |

Within the following Box Integration simulations, the error of the discrete approximations is defined as:

| (1.6) |

The first meshing method places the grid points with nearly constant grid density. The only constraint for the grid density is a maximum allowable triangle area, to achieve the different grid densities. A typical grid produced by the Delaunay triangulator triangle [61] is shown in Figure 1.2.

![\includegraphics[width=9.8cm]{ex0/normal_237nn.eps}](img59.png)

|

![\includegraphics[width=9.8cm]{ex0/iso_17_14nn.eps}](img60.png)

|

The adapted grid generation method places the grid points quasi-orthogonally (Figure 1.3), which means a constant number of points ![]() with equidistant point spacings along the expected equipotential surfaces (lines with constant radius) and a constant number of grid points

with equidistant point spacings along the expected equipotential surfaces (lines with constant radius) and a constant number of grid points ![]() with radially increasing point distances in the perpendicular direction (along the diametric lines). This way, the number of grid points along and across the radial lines can be varied arbitrarily. The resulting grid is a triangular grid with

with radially increasing point distances in the perpendicular direction (along the diametric lines). This way, the number of grid points along and across the radial lines can be varied arbitrarily. The resulting grid is a triangular grid with

![]() grid points. Figure 1.2 and Figure 1.3 contain approximately the same number of grid points.

grid points. Figure 1.2 and Figure 1.3 contain approximately the same number of grid points.

In Figure 1.4 the error of the numerical solution on the adapted grid with ![]() ,

, ![]() ,

,

![]() ticks in radial direction, as a function of the total number of grid points is displayed. An interesting aspect derived by this error analysis is that the error reaches a minimal value, if the tangential and radial number of grid ticks lie within the same value. In this example for instance exactly at

ticks in radial direction, as a function of the total number of grid points is displayed. An interesting aspect derived by this error analysis is that the error reaches a minimal value, if the tangential and radial number of grid ticks lie within the same value. In this example for instance exactly at

![]() grid ticks, but also verified by trials with other numbers of radial and tangential ticks. An additional increase of tangential sampling points does not improve the solution.

grid ticks, but also verified by trials with other numbers of radial and tangential ticks. An additional increase of tangential sampling points does not improve the solution.

![\includegraphics[width=12cm]{ex0/e22}](img67.png)

|

![\includegraphics[width=12cm]{ex0/e1}](img68.png)

|

By varying the number of ticks radially and axially, the error depending on the total number of grid points is compared to the unstructured method. This can bee seen in Figure 1.5. The conclusion is, as expected, that within the adapted point placement the error differs by orders of magnitude.

Within the simulation range of grid points an error dependency of

![]() can be expected for the unstructured method and about

can be expected for the unstructured method and about

![]() for the more sophisticated method.

for the more sophisticated method.

Thus, the evaluation of the numerical solution on the unstructured grid needs about ![]() times the number of grid points than the improved version to achieve equal accuracy -- also implicating the same factor for memory and time consumption. Within three-dimensional simulations this aspect becomes even more severe.

times the number of grid points than the improved version to achieve equal accuracy -- also implicating the same factor for memory and time consumption. Within three-dimensional simulations this aspect becomes even more severe.