|

|

||||

BiographyDiego Milardovich was born in Rosario, Argentina in 1992. He received his Master's degree in Electronic Engineering at the National University of Rosario in 2019. In February 2020, he joined the Institute for Microelectronics at the TU Wien, where he is currently working on his doctoral degree focusing on atomistic modeling of insulator defects. His previous experiences include 1 year as a research assistant at the Neuroscience and Biomedical Engineering department of Aalto University (Helsinki, Finland), 2 years as an engineering officer at Nestlé (Firmat, Argentina) and 3 months as a research engineer at Techint (Buenos Aires, Argentina). |

|||||

Machine Learning Prediction of Defect Structures in Amorphous SiO2

The study of defect formations and structures in amorphous materials plays a crucial role in the development of a wide range of modern microelectronic devices and technologies. The calculations required in these studies are routinely performed with density functional theory (DFT). However, this approach is remarkably expensive from a computational point of view. This disadvantage limits its application to relatively small systems (on the order of a few hundred atoms) and particularly short simulation times (on the order of tens of ps).

In this context, machine learning (ML) based solutions have great potential for drastically reducing the computational effort required to study the formation and structure of defects in complex atomistic structures, by either aiding or even replacing currently used methods. We developed an ML-based framework to predict the formation and structure of defects in atomistic structures. This framework takes as input a defect-free atomistic structure and an atom of interest within it, and it outputs the defect-having structure at the particular site of interest.

This framework works by representing the atomistic environment around the atom of interest in the input defect-free structure with a descriptor. A descriptor is a mathematical representation (i.e., a vector or matrix) of a particular atomistic environment or structure. This vector is used as an input to a trained ML model, which predicts the descriptor of the defect-having structure. An optimization method is used to adjust the coordinates of the atoms in the input defect-free structure until its descriptor matches the ML-predicted descriptor for the defect-having structure. The final result is the defect-having structure, and the whole process is computationally inexpensive, taking roughly 1 second to complete on a standard desktop computer. The results are validated by comparing the ML-predicted defect-having structures with structures created by DFT-relaxation.

In our work, we applied this framework to the study of hydroxyl E' center defects in amorphous silicon dioxide (a-SiO2). However, due to the modularity of our approach, it can also be applied to the study of other defects and/or materials.

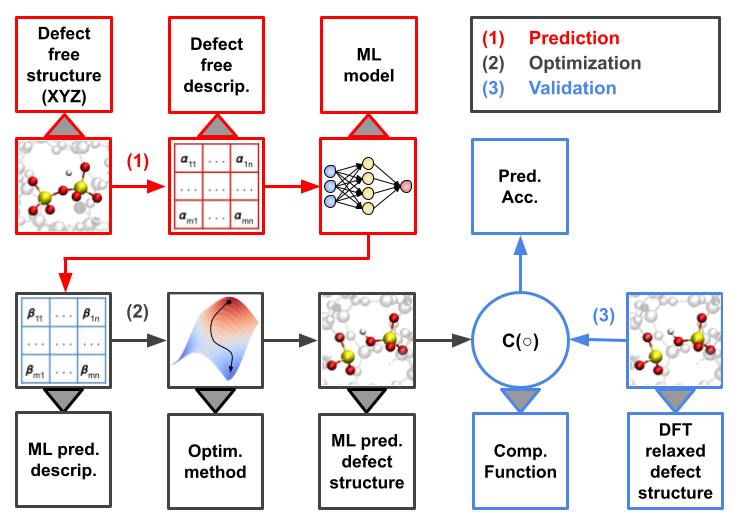

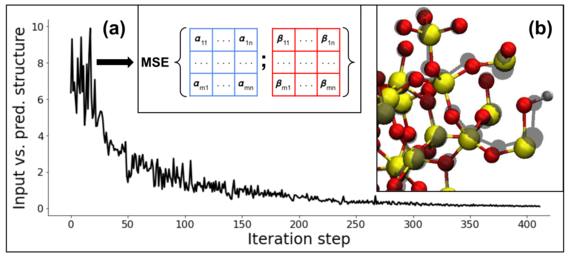

A schematic representation of our proposed workflow is shown in Fig. 1. An example of its application can be seen in Fig. 2, where it was used to predict the formation and structure of an hydroxyl E' center defect in an a-SiO2 structure.

Fig. 1: Schematic representation of our proposed workflow to predict the formation and structure of defects in atomistic structures. (1) The atomistic environment around the atom of interest in the defect-free structure is represented with a descriptor. This mathematical representation is used as an input into an ML model to predict the descriptor of the defect-having structure. (2) An optimization method is used to adjust the coordinates of the atoms in the input structure, until its descriptor matches the ML-predicted descriptor for the defect-having structure. (3) The final result is the defect-having structure, and it is validated by comparing it with its equivalent DFT-relaxed structure.

Fig. 2: Application of our framework to predict the formation of an hydroxyl E' center defect in an a-SiO2 structure. (a) An optimization method is used to adjust the coordinates of the atoms in the input structure until their descriptor (represented by the blue matrix) matches the ML-predicted descriptor for the defect-having structure (represented by the red matrix). (b) The final result of the process is the defect-having structure (color), which is validated by comparing it to its DFT-relaxed equivalent (shadow).