The observed spin lifetime in unstrained thin films is much different compared

to bulk samples. Experiments show a dramatic reduction of the spin relaxation

time in Si/SiO

4.4.1 Spin Lifetime Enhancement with Shear Strain

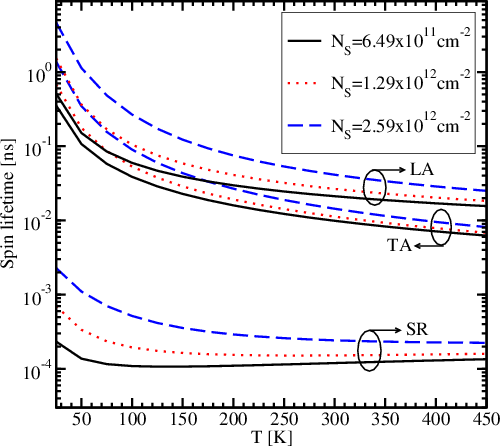

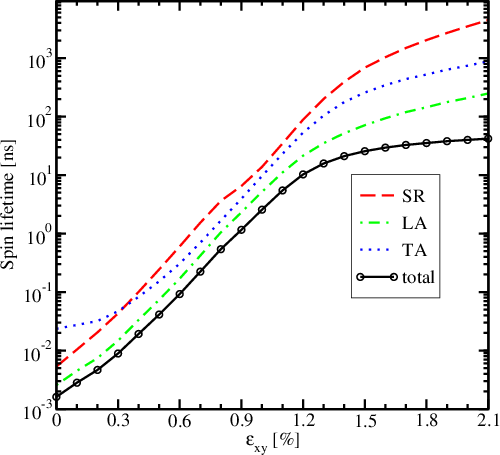

Figure 4.11 shows the contributions of the surface roughness (

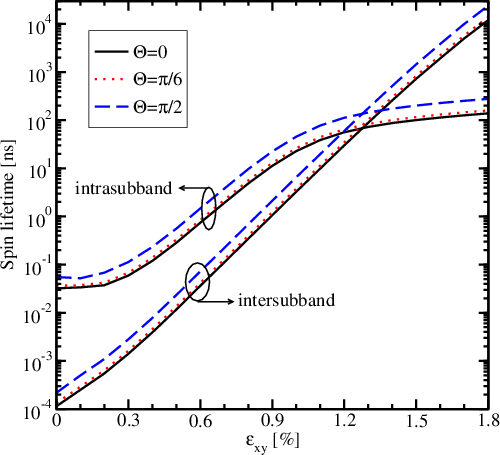

4.4.2 Inter- and Intrasubband Components

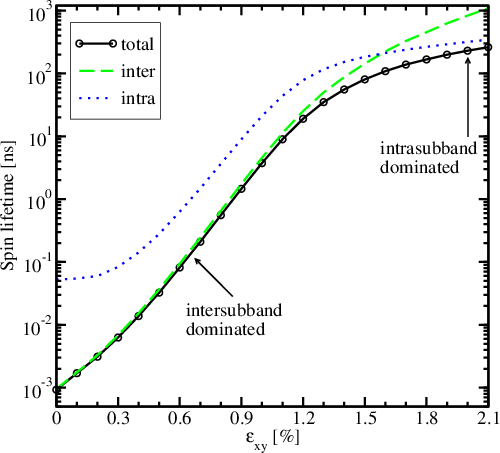

In order to elucidate the spin relaxation mechanism, the spin-flip caused by

the intra- and intersubband scattering must be analyzed. The corresponding

components of the spin lifetime at the room temperature (RT) for a sample

thickness of

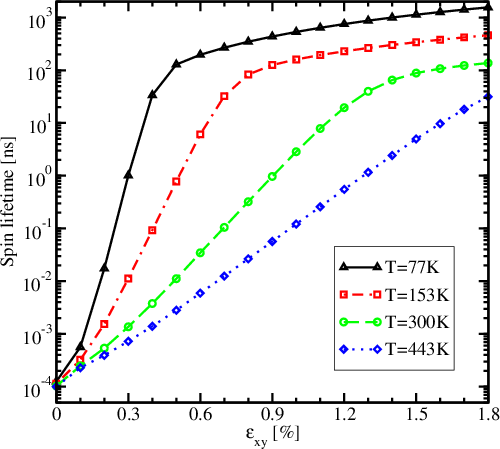

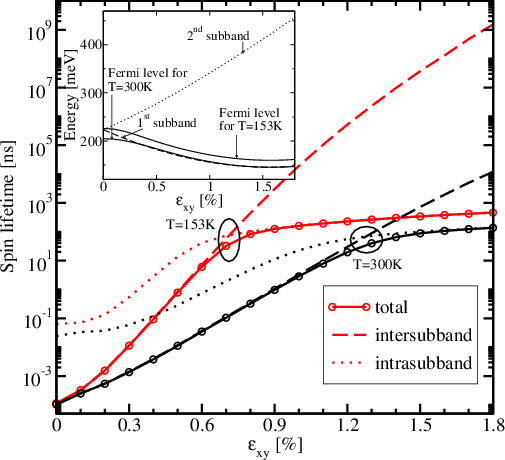

Figure 4.14 delineates the surface roughness induced spin relaxation time with

its inter- and intrasubband components at two distinct temperatures and at a

very low sample thickness. One can see that, when the temperature decreases the

Fermi level energy increases (c.f. Figure 4.14 inset), the intersubband scattering

becomes less efficient already at lower values of the shear strain component

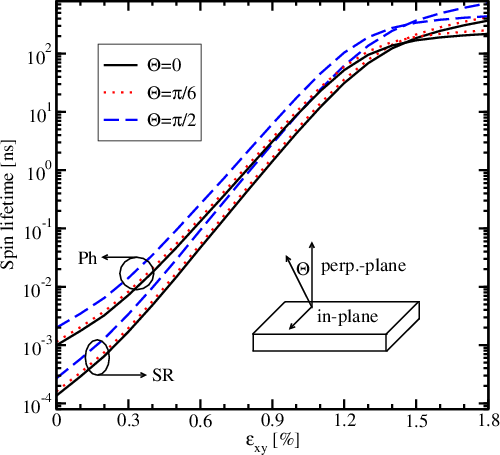

4.4.3 Effect of Spin Injection Orientation

Figure 4.15 shows how the surface roughness and the phonon mediated

components of the total spin lifetime (denoted as

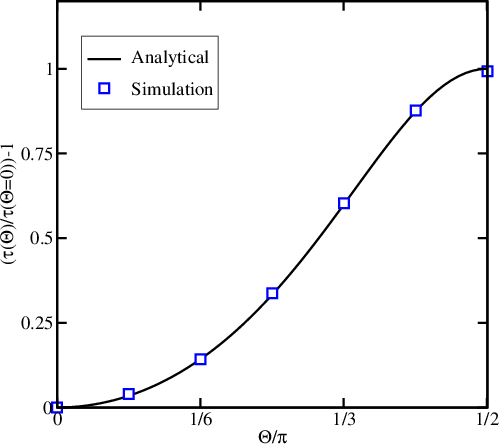

Now, one needs to investigate the dependence of the total spin lifetime

| (4.37) |

In such a condition,

| (4.38) |

and therefore,

| (4.39) |

So, the total spin lifetime