The thermal conductivity  parametrizes the flux term in the heat flux

equation and depicts the energy flux per area and temperature difference

transported within a homogeneous material. Measurement of the thermal

conductivity is conventionally based on gathering the temperature difference

caused by a steady heat flow, but also more sophisticated approaches like the

parametrizes the flux term in the heat flux

equation and depicts the energy flux per area and temperature difference

transported within a homogeneous material. Measurement of the thermal

conductivity is conventionally based on gathering the temperature difference

caused by a steady heat flow, but also more sophisticated approaches like the

-method can be applied in special cases [215]. The total

thermal conductivity in semiconductors consists of the lattice and the

electronic contribution, which is connected to the electrical conductivity by a

Wiedemann-Franz law. While the lattice thermal conductivity, which is the

dominant mechanism over a wide range of carrier concentrations in silicon,

germanium, and several III-V semiconductors, is commonly modeled as a

temperature dependent power law [133], the electron or hole

contribution in n- and p-type materials gains weight in heavily doped samples.

In the intrinsic range, both electrons and holes contribute to the thermal

conductivity, which is referred to as the bipolar contribution. In lead

telluride, these additional contributions to the thermal conductivity caused

by the carrier gas play already a significant role at technically relevant

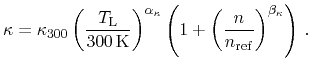

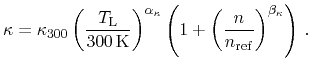

carrier concentrations [121]. Based on the theoretical

considerations presented in [125], the thermal conductivity

dependence on the temperature and the electron concentration can be modeled as

-method can be applied in special cases [215]. The total

thermal conductivity in semiconductors consists of the lattice and the

electronic contribution, which is connected to the electrical conductivity by a

Wiedemann-Franz law. While the lattice thermal conductivity, which is the

dominant mechanism over a wide range of carrier concentrations in silicon,

germanium, and several III-V semiconductors, is commonly modeled as a

temperature dependent power law [133], the electron or hole

contribution in n- and p-type materials gains weight in heavily doped samples.

In the intrinsic range, both electrons and holes contribute to the thermal

conductivity, which is referred to as the bipolar contribution. In lead

telluride, these additional contributions to the thermal conductivity caused

by the carrier gas play already a significant role at technically relevant

carrier concentrations [121]. Based on the theoretical

considerations presented in [125], the thermal conductivity

dependence on the temperature and the electron concentration can be modeled as

|

(5.15) |

The according parameters are collected in Table 5.6.

Table 5.6:

Parameter values for the lead telluride thermal conductivity model

incorporating the carrier contribution.

|

|

In Fig. 5.3, the agreement between Bhandari's data

[125] and the model is illustrated. Several measurement data

available in literature [216,217,218,219] show a

general decrease of the thermal conductivity for increasing temperatures with

an alleviated or even reverse trend at higher temperatures caused by the

increased electronic contribution due to additionally available free carriers.

Figure 5.3:

Dependence of the thermal conductivity of lead telluride on the

lattice temperature and carrier concentration. While red glyphs depict Bhandari's

data [125], the surface denotes the modeled thermal

conductivity.

|

![\includegraphics[width=10cm]{figures/materials/PbTe/therm_cond.eps}](img676.png) |

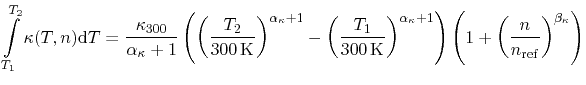

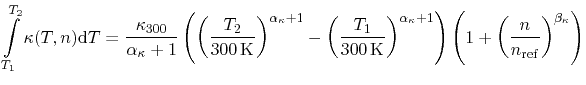

The heat flux between two points with temperatures

and

and

is

calculated by the integral

is

calculated by the integral

|

(5.16) |

assuming the carrier concentration to be constant throughout the discretization

box.

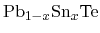

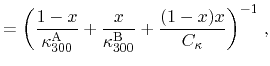

In Pb Sn

Sn Te, alloy scattering enters as an additional mechanism and

thus the thermal conductivity is drastically reduced compared to pure PbTe and

SnTe. Fig. 5.4 depicts the variation of the thermal

conductivity with respect to the material composition at

Te, alloy scattering enters as an additional mechanism and

thus the thermal conductivity is drastically reduced compared to pure PbTe and

SnTe. Fig. 5.4 depicts the variation of the thermal

conductivity with respect to the material composition at

.

Measurement data have been collected from

[220,221,222], where the latter two comprise

investigations of sintered samples which explains the lower thermal

conductivity values. The lattice component has been theoretically investigated

by molecular-dynamics studies in [223] and by subtracting the

electronic contribution

.

Measurement data have been collected from

[220,221,222], where the latter two comprise

investigations of sintered samples which explains the lower thermal

conductivity values. The lattice component has been theoretically investigated

by molecular-dynamics studies in [223] and by subtracting the

electronic contribution

|

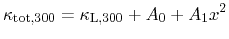

(5.17) |

derived from the electron conductivity  , the Lorentz number

, the Lorentz number  and

the temperature [220]. The model for the material composition

dependent thermal conductivity in alloys reads [133]

and

the temperature [220]. The model for the material composition

dependent thermal conductivity in alloys reads [133]

where  and

and  denote the SnTe and PbTe content, respectively.

denote the SnTe and PbTe content, respectively.

is the thermal conductivity for PbTe at room temperature,

is the thermal conductivity for PbTe at room temperature,

analogously for SnTe, and

analogously for SnTe, and  the bowing factor accounting for the alloy

scattering reduction of the thermal conductivity. The exponents describing the

temperature dependence are interpolated linearly between the values for the

pure material constituents.

The additional electronic contribution can be estimated by

the bowing factor accounting for the alloy

scattering reduction of the thermal conductivity. The exponents describing the

temperature dependence are interpolated linearly between the values for the

pure material constituents.

The additional electronic contribution can be estimated by

|

(5.20) |

for Pb Sn

Sn Te based on the data published in [220].

According values for the temperature exponents

Te based on the data published in [220].

According values for the temperature exponents

and

and

have been identified for the lattice thermal conductivity

based on data published in [222] and [224]. The

parameters for the material composition dependent thermal conductivity model

are collected in Table 5.7.

have been identified for the lattice thermal conductivity

based on data published in [222] and [224]. The

parameters for the material composition dependent thermal conductivity model

are collected in Table 5.7.

Table 5.7:

Parameter values for the material composition dependent PbSnTe thermal conductivity models.

|

|

A decrease of the thermal conductivity compared to single crystals due to grain

boundary scattering in sintered materials has been reported in

[124,126,225] to be as high as  in pure lead

telluride and

in pure lead

telluride and  in disordered lead telluride alloys. However, a

drastic decrease of the thermal conductivity is reported in [128]

for grain sizes in the range of

in disordered lead telluride alloys. However, a

drastic decrease of the thermal conductivity is reported in [128]

for grain sizes in the range of

. Furthermore, the

influence of the grain size within sintered

. Furthermore, the

influence of the grain size within sintered

is investigated in

[127] for hot and cold pressed materials. Recent work has dealt with

the dependence of the thermal conductivity on the pressure during fabrication

using high temperature and high pressure processes [226,227].

is investigated in

[127] for hot and cold pressed materials. Recent work has dealt with

the dependence of the thermal conductivity on the pressure during fabrication

using high temperature and high pressure processes [226,227].

M. Wagner: Simulation of Thermoelectric Devices

![]() parametrizes the flux term in the heat flux

equation and depicts the energy flux per area and temperature difference

transported within a homogeneous material. Measurement of the thermal

conductivity is conventionally based on gathering the temperature difference

caused by a steady heat flow, but also more sophisticated approaches like the

parametrizes the flux term in the heat flux

equation and depicts the energy flux per area and temperature difference

transported within a homogeneous material. Measurement of the thermal

conductivity is conventionally based on gathering the temperature difference

caused by a steady heat flow, but also more sophisticated approaches like the

![]() -method can be applied in special cases [215]. The total

thermal conductivity in semiconductors consists of the lattice and the

electronic contribution, which is connected to the electrical conductivity by a

Wiedemann-Franz law. While the lattice thermal conductivity, which is the

dominant mechanism over a wide range of carrier concentrations in silicon,

germanium, and several III-V semiconductors, is commonly modeled as a

temperature dependent power law [133], the electron or hole

contribution in n- and p-type materials gains weight in heavily doped samples.

In the intrinsic range, both electrons and holes contribute to the thermal

conductivity, which is referred to as the bipolar contribution. In lead

telluride, these additional contributions to the thermal conductivity caused

by the carrier gas play already a significant role at technically relevant

carrier concentrations [121]. Based on the theoretical

considerations presented in [125], the thermal conductivity

dependence on the temperature and the electron concentration can be modeled as

-method can be applied in special cases [215]. The total

thermal conductivity in semiconductors consists of the lattice and the

electronic contribution, which is connected to the electrical conductivity by a

Wiedemann-Franz law. While the lattice thermal conductivity, which is the

dominant mechanism over a wide range of carrier concentrations in silicon,

germanium, and several III-V semiconductors, is commonly modeled as a

temperature dependent power law [133], the electron or hole

contribution in n- and p-type materials gains weight in heavily doped samples.

In the intrinsic range, both electrons and holes contribute to the thermal

conductivity, which is referred to as the bipolar contribution. In lead

telluride, these additional contributions to the thermal conductivity caused

by the carrier gas play already a significant role at technically relevant

carrier concentrations [121]. Based on the theoretical

considerations presented in [125], the thermal conductivity

dependence on the temperature and the electron concentration can be modeled as

![\includegraphics[width=10cm]{figures/materials/PbTe/therm_cond.eps}](img676.png)

![]() and

and

![]() is

calculated by the integral

is

calculated by the integral

![\includegraphics[width=10cm]{figures/materials/PbTe/therm_cond_PbSnTe.eps}](img680.png)

![]() Sn

Sn![]() Te, alloy scattering enters as an additional mechanism and

thus the thermal conductivity is drastically reduced compared to pure PbTe and

SnTe. Fig. 5.4 depicts the variation of the thermal

conductivity with respect to the material composition at

Te, alloy scattering enters as an additional mechanism and

thus the thermal conductivity is drastically reduced compared to pure PbTe and

SnTe. Fig. 5.4 depicts the variation of the thermal

conductivity with respect to the material composition at

![]() .

Measurement data have been collected from

[220,221,222], where the latter two comprise

investigations of sintered samples which explains the lower thermal

conductivity values. The lattice component has been theoretically investigated

by molecular-dynamics studies in [223] and by subtracting the

electronic contribution

.

Measurement data have been collected from

[220,221,222], where the latter two comprise

investigations of sintered samples which explains the lower thermal

conductivity values. The lattice component has been theoretically investigated

by molecular-dynamics studies in [223] and by subtracting the

electronic contribution

![]() in pure lead

telluride and

in pure lead

telluride and ![]() in disordered lead telluride alloys. However, a

drastic decrease of the thermal conductivity is reported in [128]

for grain sizes in the range of

in disordered lead telluride alloys. However, a

drastic decrease of the thermal conductivity is reported in [128]

for grain sizes in the range of

![]() . Furthermore, the

influence of the grain size within sintered

. Furthermore, the

influence of the grain size within sintered

![]() is investigated in

[127] for hot and cold pressed materials. Recent work has dealt with

the dependence of the thermal conductivity on the pressure during fabrication

using high temperature and high pressure processes [226,227].

is investigated in

[127] for hot and cold pressed materials. Recent work has dealt with

the dependence of the thermal conductivity on the pressure during fabrication

using high temperature and high pressure processes [226,227].