4.3.10 Examples

This section depicts several examples to show the usability of the introduced device simulator

approach. The examples are chosen to depict the multi-dimensional support as well as the

device template mechanism, the different simulation problems, and the stepping facility.

Implementation details as well as simulation results are shown.

One-Dimensional Capacitor

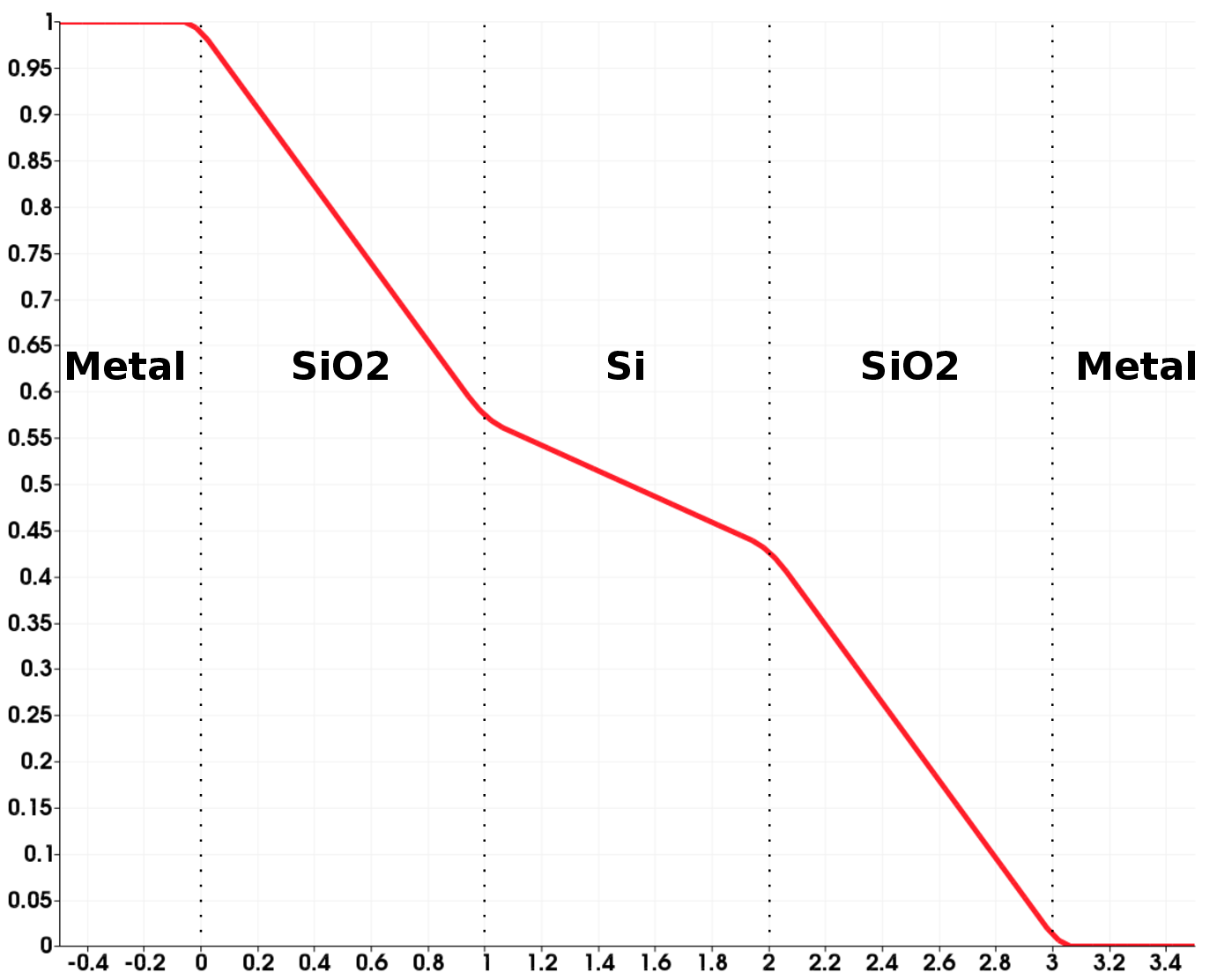

This section discusses a one-dimensional capacitor device, solving the Laplace problem

(Section 4.3.6). This particular case has been chosen to depict the support for

one-dimensional devices, usually required for developing and debugging more advanced

models. Therefore, this rather trivial device is required to be supported by every device

simulator, before delving into more complicated models.

The device consists of five segments; two metal contact segments are attached to

either side of a silicon dioxide-silicon-silicon dioxide (SiO -Si-SiO

-Si-SiO ) structure,

both assigned as Dirichlet contacts. As the implementation of the Laplace

problem

keeps the permittivity on the left side of the equation (Section 4.3.6), the potential

reflects the transition between the materials, as shown in Figure 4.16. The potential

drops more significantly in the oxide segments than in the middle semiconductor

segment.

) structure,

both assigned as Dirichlet contacts. As the implementation of the Laplace

problem

keeps the permittivity on the left side of the equation (Section 4.3.6), the potential

reflects the transition between the materials, as shown in Figure 4.16. The potential

drops more significantly in the oxide segments than in the middle semiconductor

segment.

Two-Dimensional PN Diode

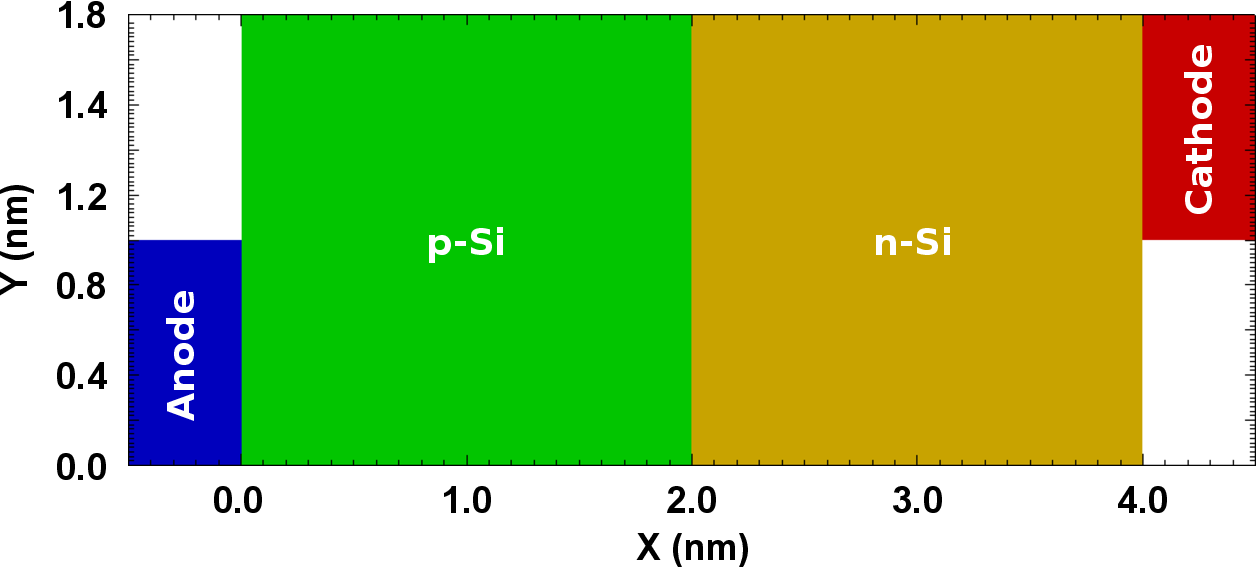

This section shows the simulation of a two-dimensional pn-junction diode. The DD problem

(Section 4.3.6) is solved for a set of contact potentials. This particular example has been

chosen to depict the support for two-dimensional devices as well as the evaluation of device

characteristics.

The device consists of four segments, where two metal contact segments are attached to

either side of a p-Si-n-Si structure (Figure 4.17). The p-Si offers a constant donor and

acceptor doping of  cm

cm and

and  cm

cm , respectively. The n-Si offers a constant donor

and acceptor doping of

, respectively. The n-Si offers a constant donor

and acceptor doping of  cm

cm and

and  cm

cm , respectively.

, respectively.

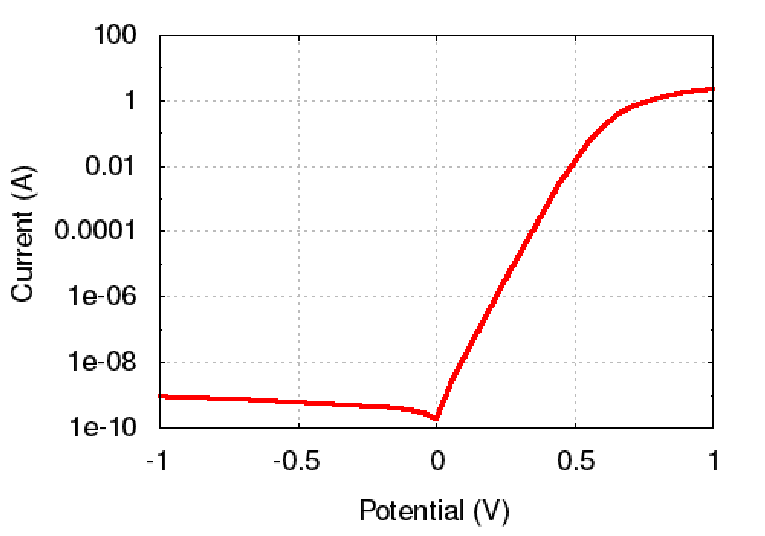

The device characteristics is computed by applying a constant cathode contact potential

by simultaneously varying the anode contact potential, ranging from  V to

V to  V, with a

stepsize of

V, with a

stepsize of  V (Figure 4.18). In forward and reverse operation a maximum current of

V (Figure 4.18). In forward and reverse operation a maximum current of

A and

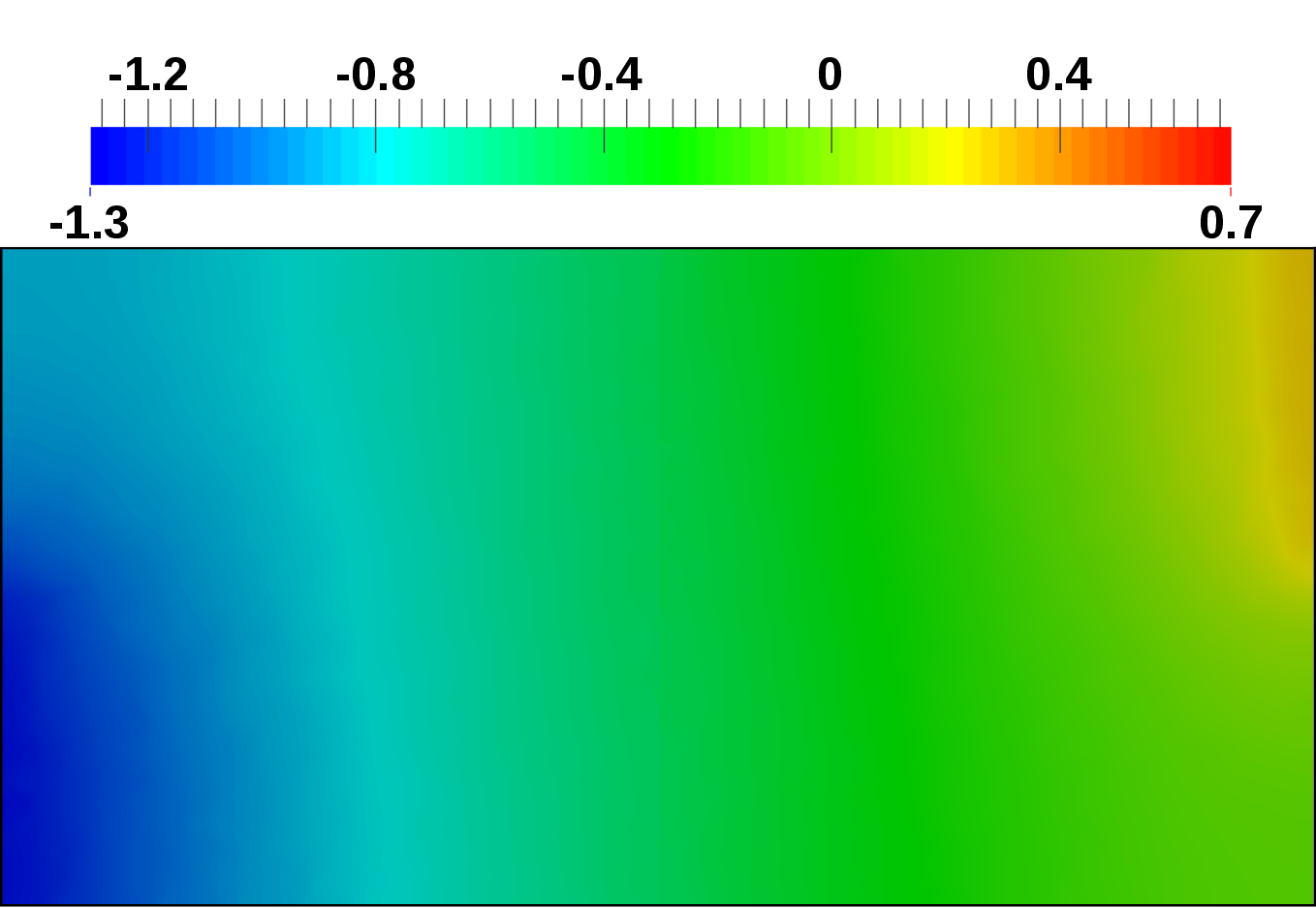

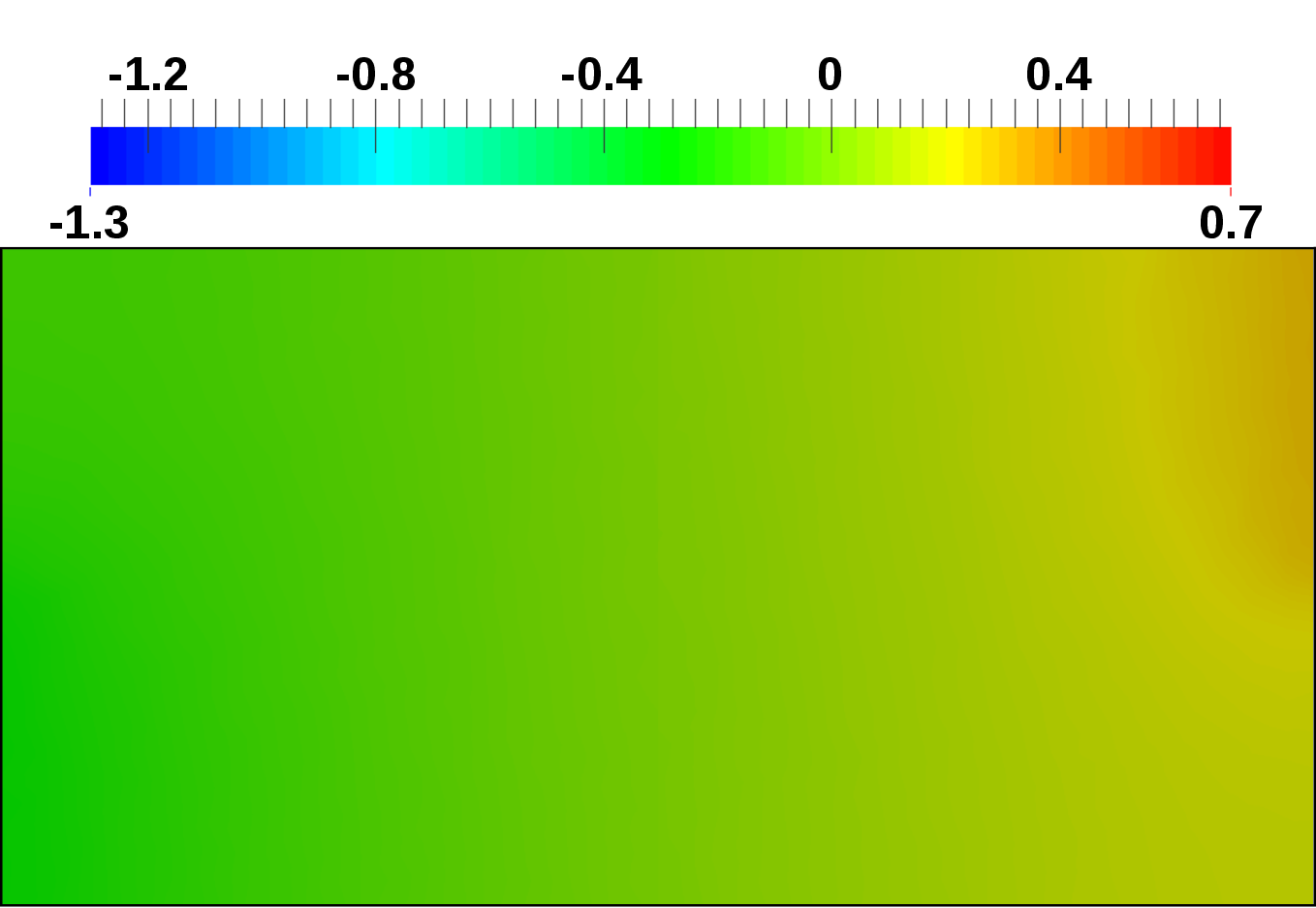

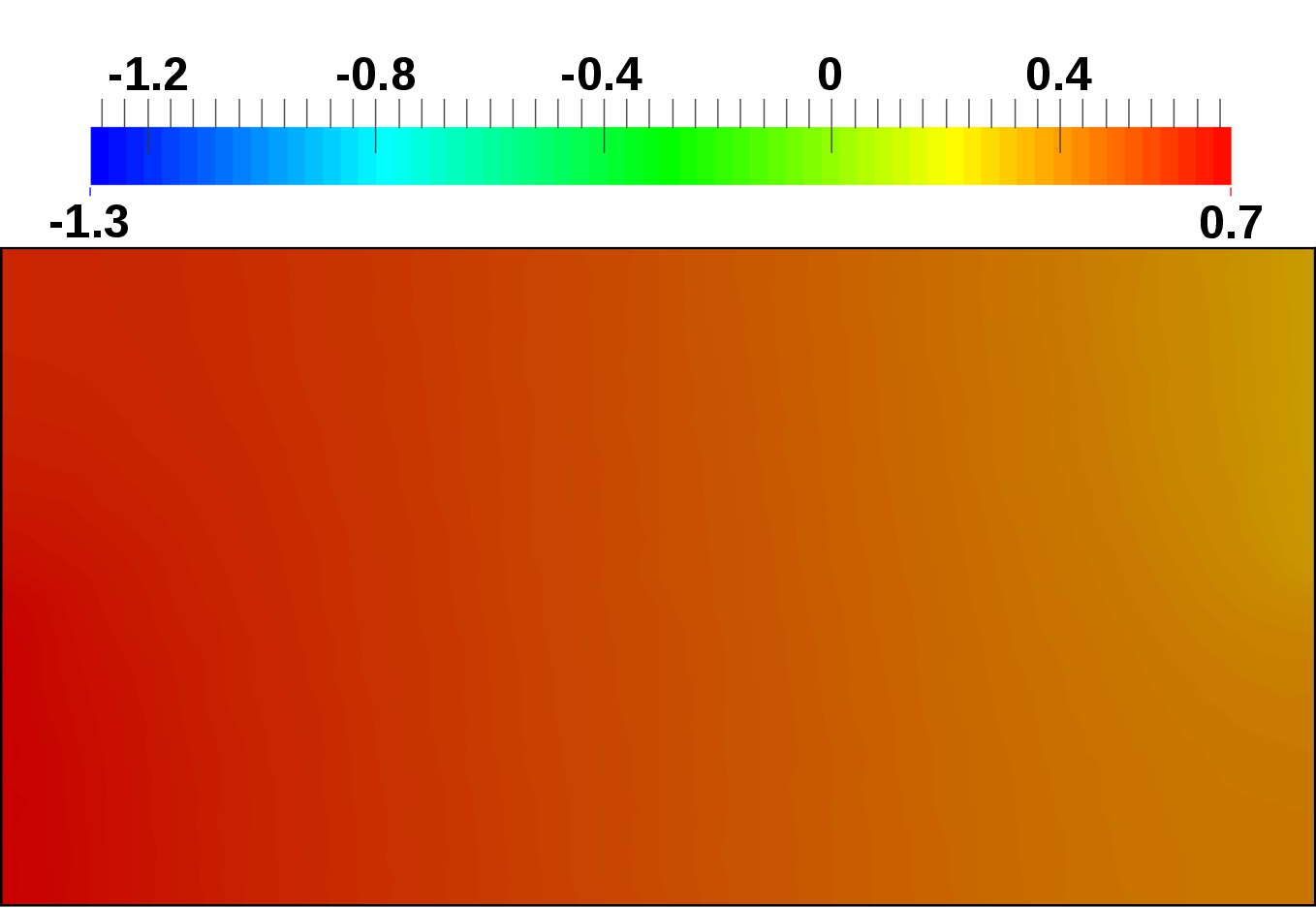

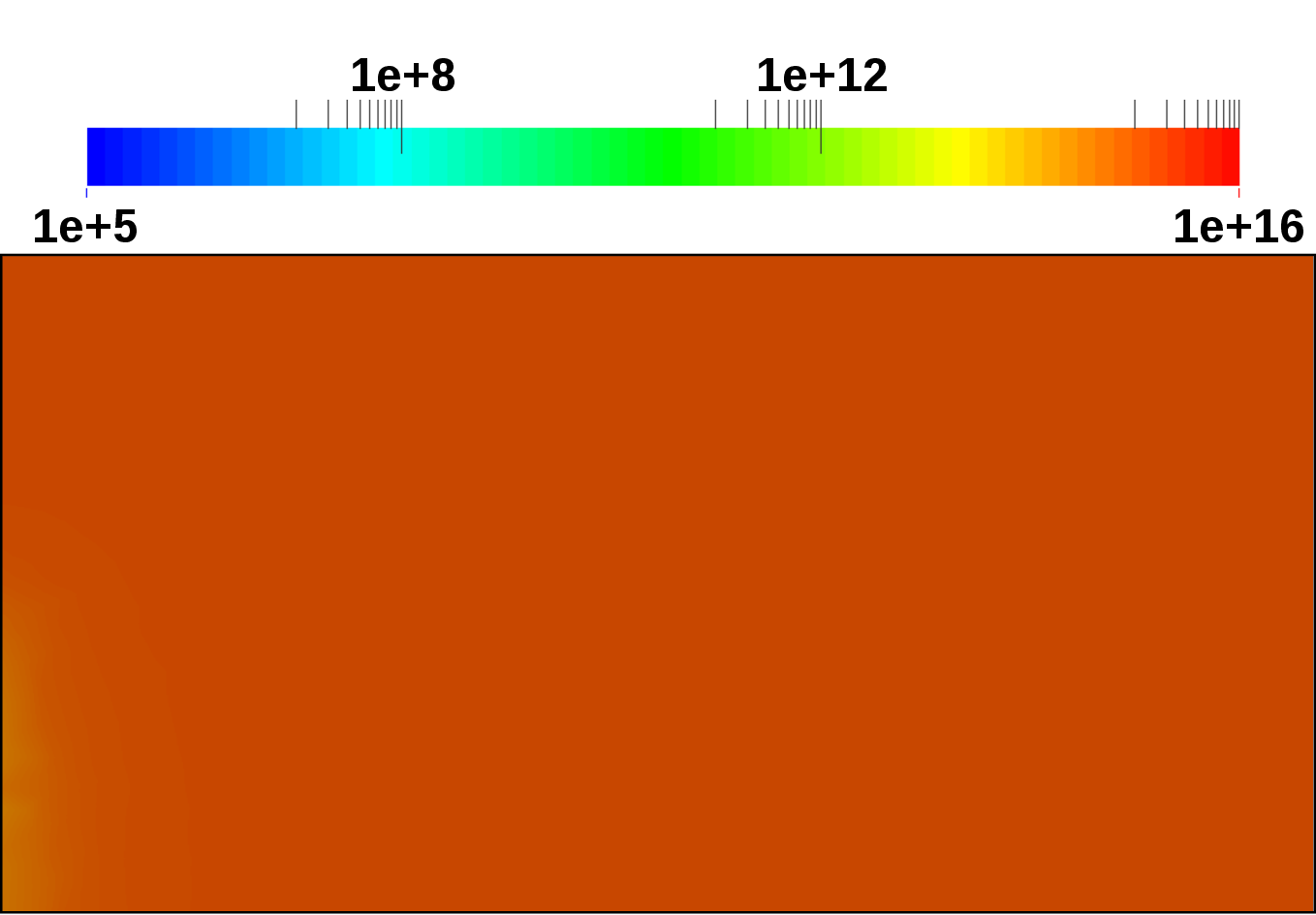

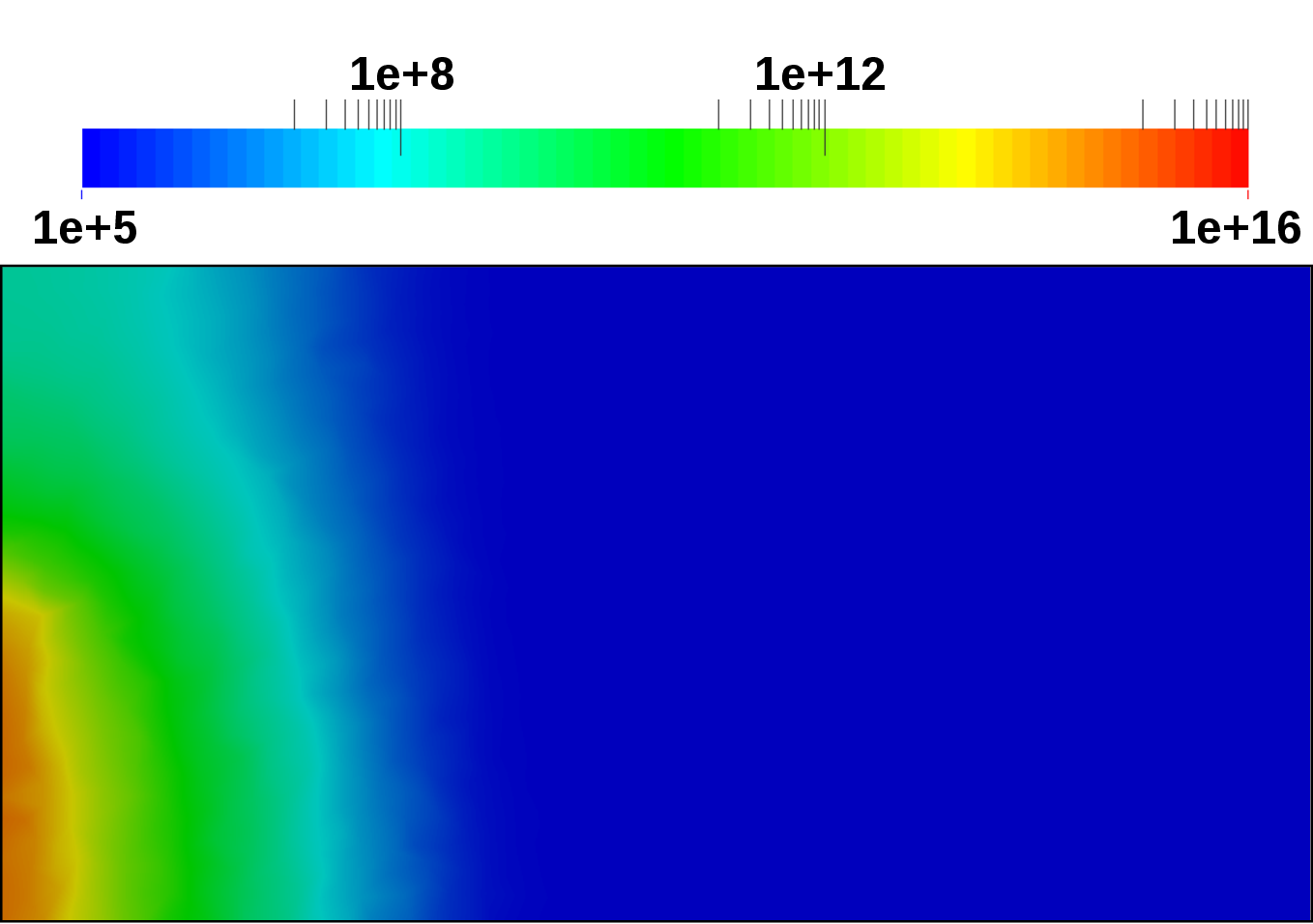

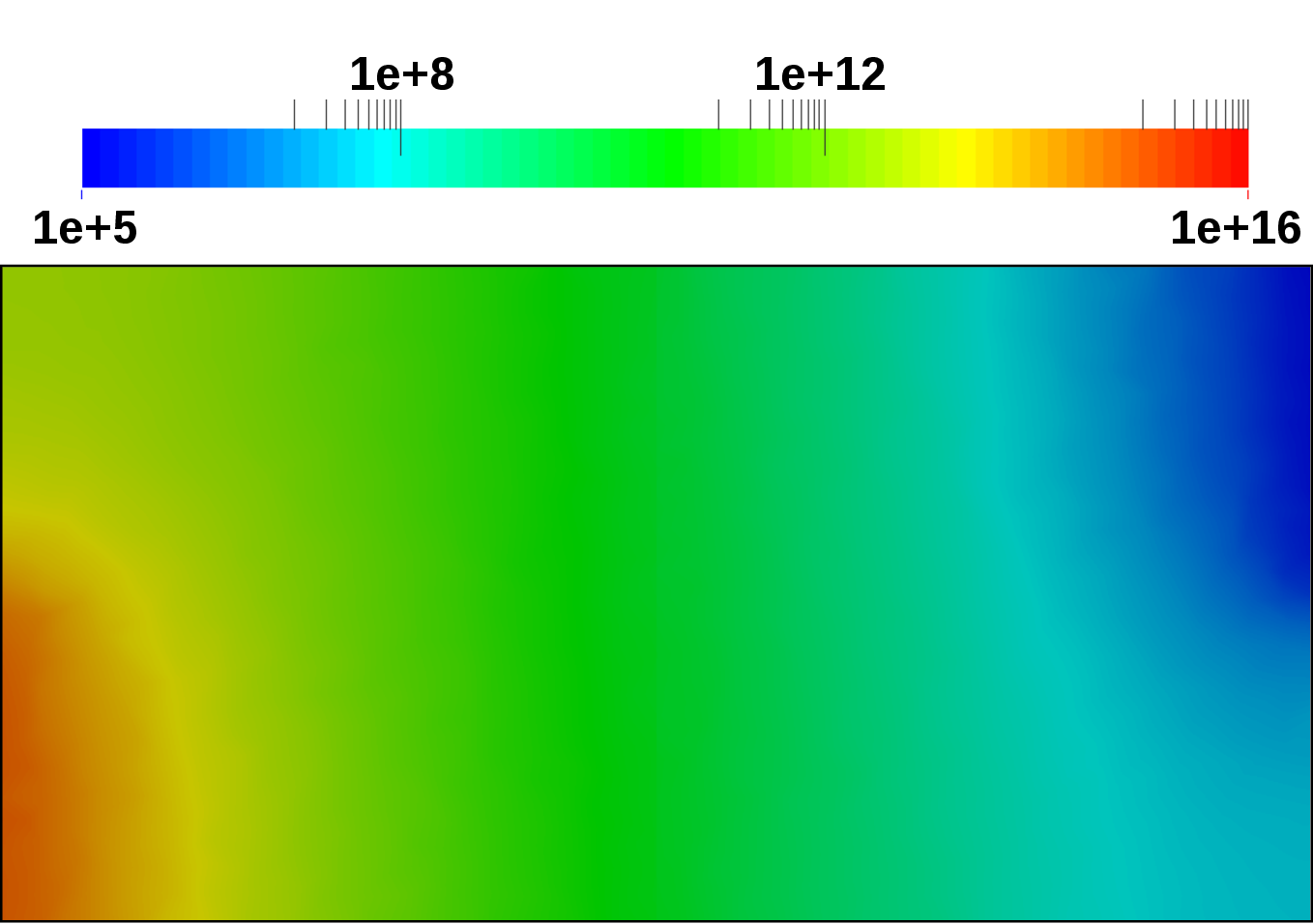

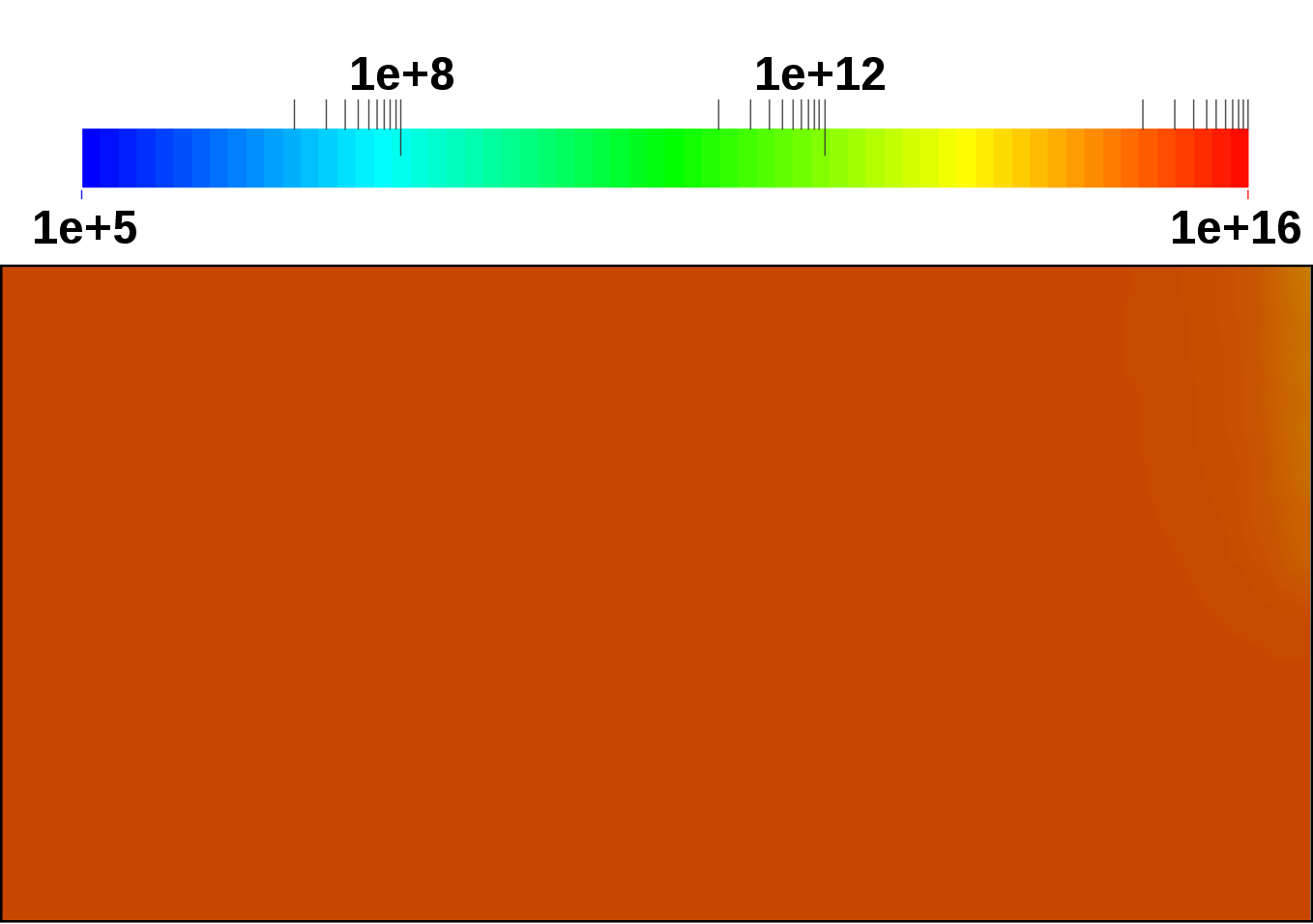

A and  nA is computed, respectively. Figure 4.19 depicts the computed potential

distributions for the reverse, equilibrium, and forward case. In the forward case, the polarity of

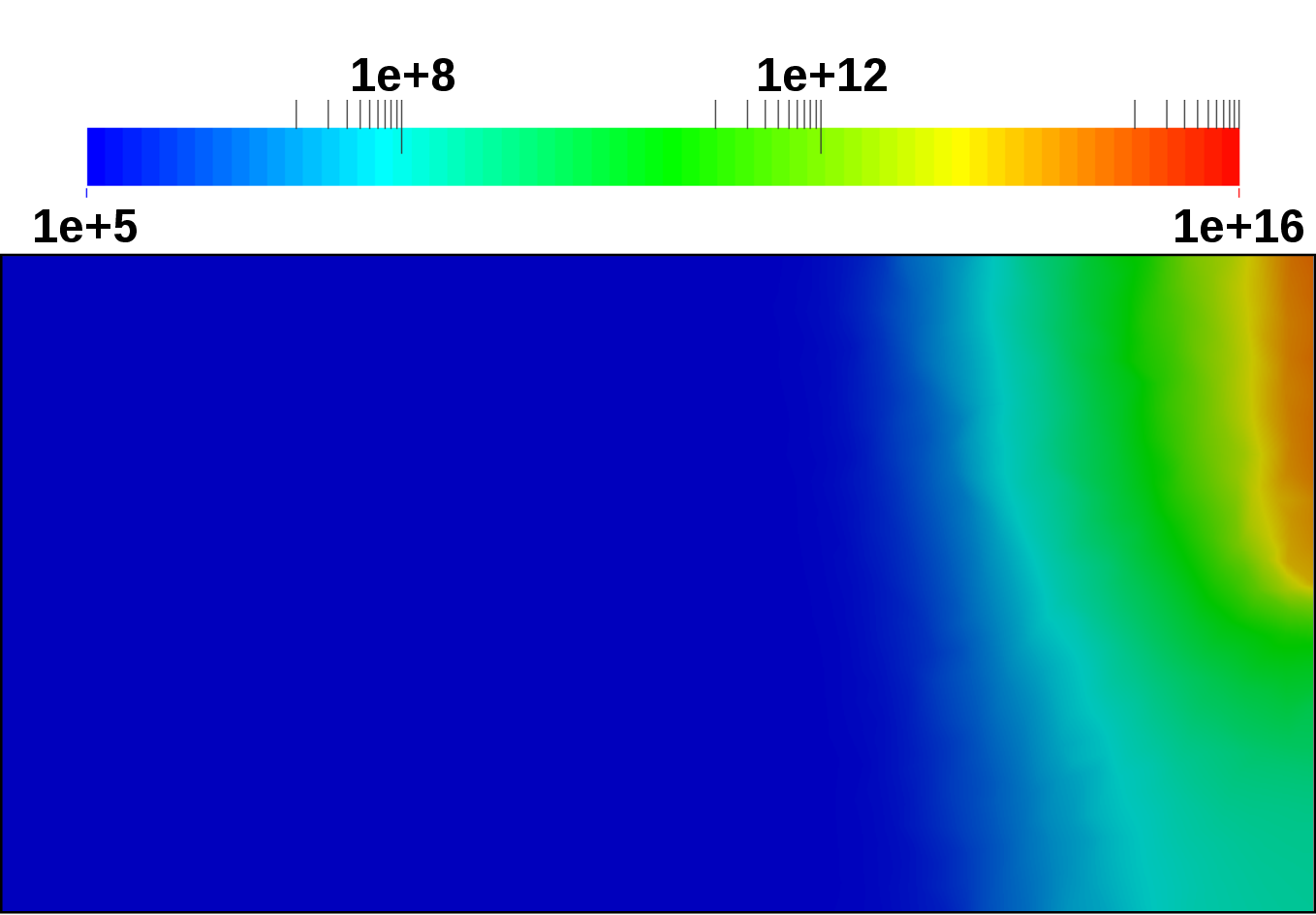

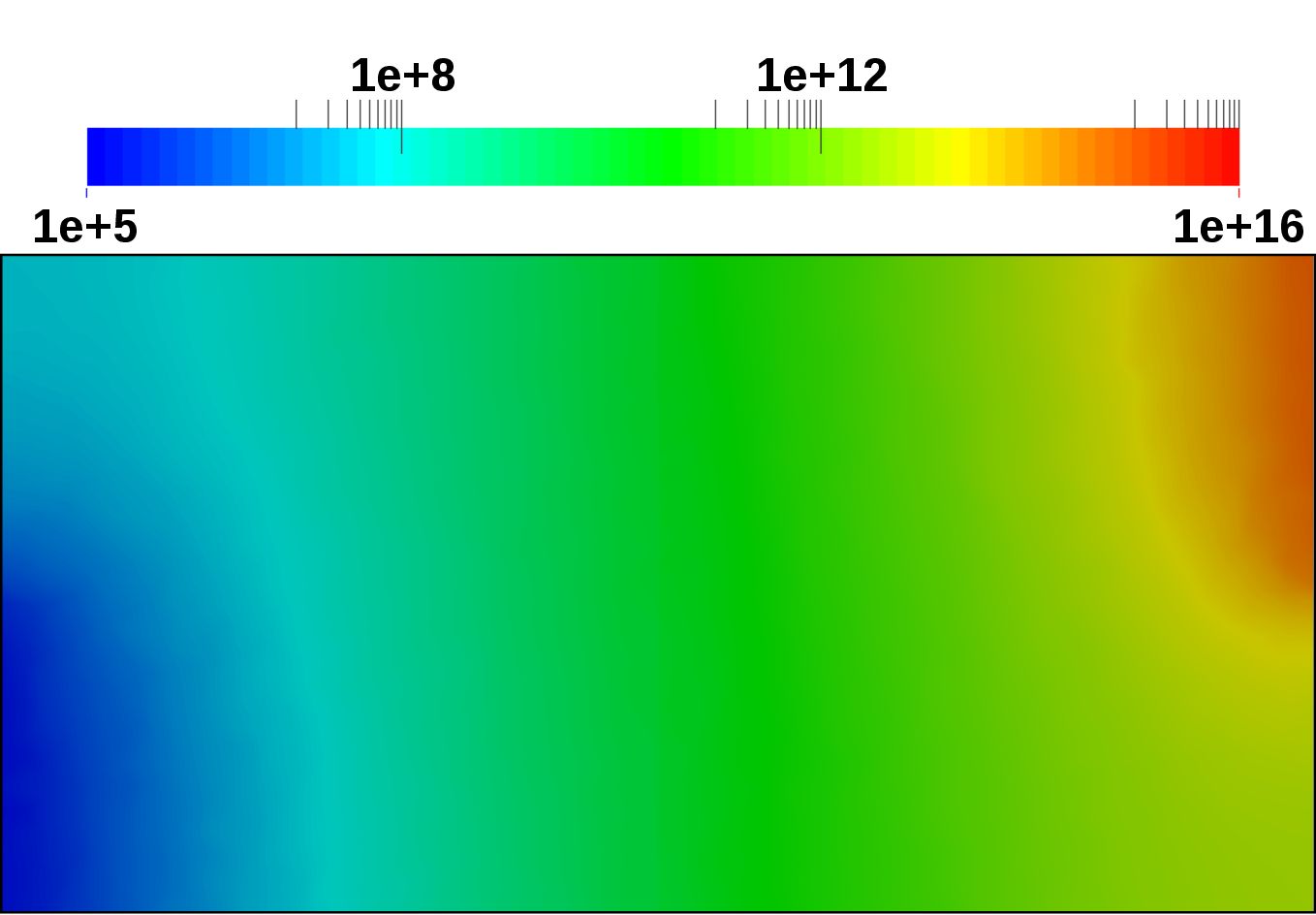

the anode contact is switched. Figure 4.20 depicts the computed electron concentration

distributions for the reverse, equilibrium, and forward case. Where in the reverse case, the

electrons retract toward the cathode contact, in the forward case the electrons are distributed

over the entire device. Figure 4.21 depicts the computed hole concentration distributions for

the reverse, equilibrium, and forward case. Where in the reverse case, the holes retract

toward the anode contact, in the forward case the holes are distributed over the entire

device.

nA is computed, respectively. Figure 4.19 depicts the computed potential

distributions for the reverse, equilibrium, and forward case. In the forward case, the polarity of

the anode contact is switched. Figure 4.20 depicts the computed electron concentration

distributions for the reverse, equilibrium, and forward case. Where in the reverse case, the

electrons retract toward the cathode contact, in the forward case the electrons are distributed

over the entire device. Figure 4.21 depicts the computed hole concentration distributions for

the reverse, equilibrium, and forward case. Where in the reverse case, the holes retract

toward the anode contact, in the forward case the holes are distributed over the entire

device.

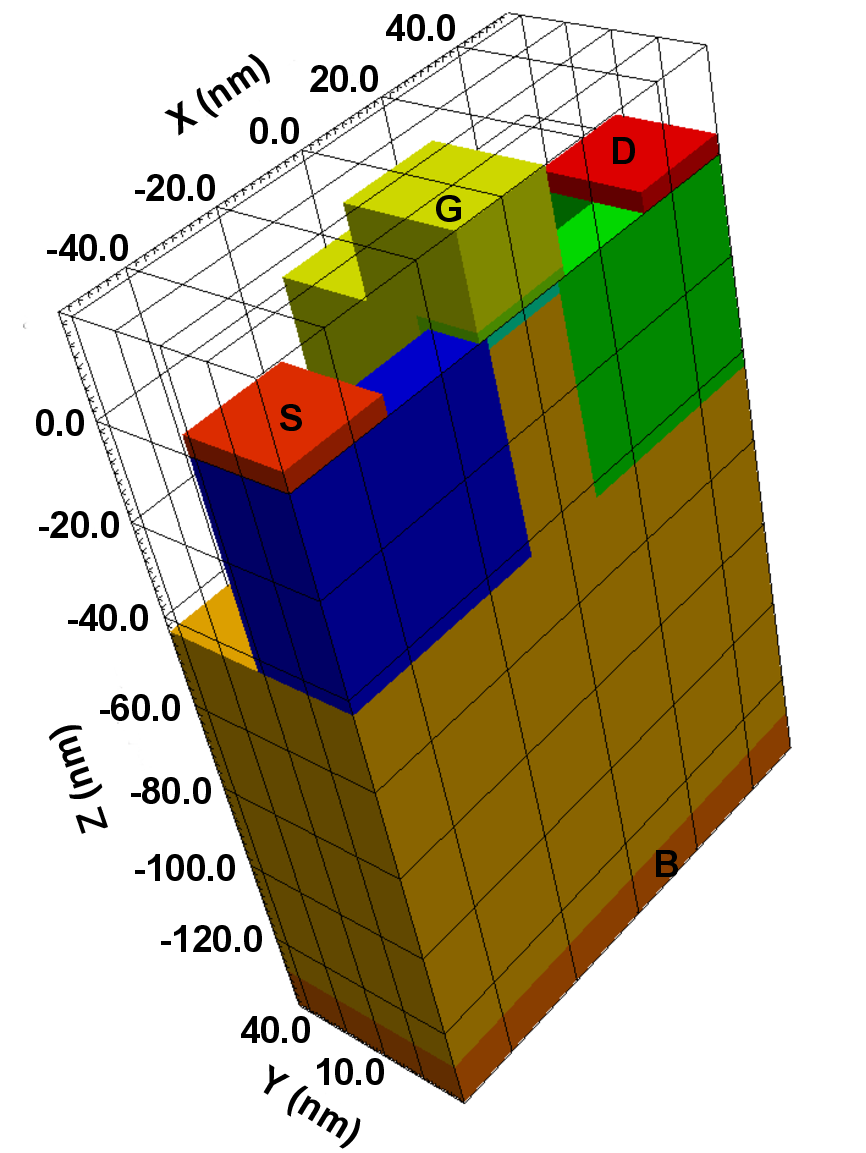

Three-Dimensional FinFET

This section shows the simulation of a three-dimensional symmetrically sliced Si-based

FinFET device, based on solving the DD problem (Section 4.3.6). This particular example has

been chosen to depict the support for three-dimensional devices.

Figure 4.22 depicts the device setup. The source and drain region are set at a constant

donor doping of  cm

cm , whereas the bulk region is set at a constant acceptor doping of

, whereas the bulk region is set at a constant acceptor doping of

cm

cm .

.

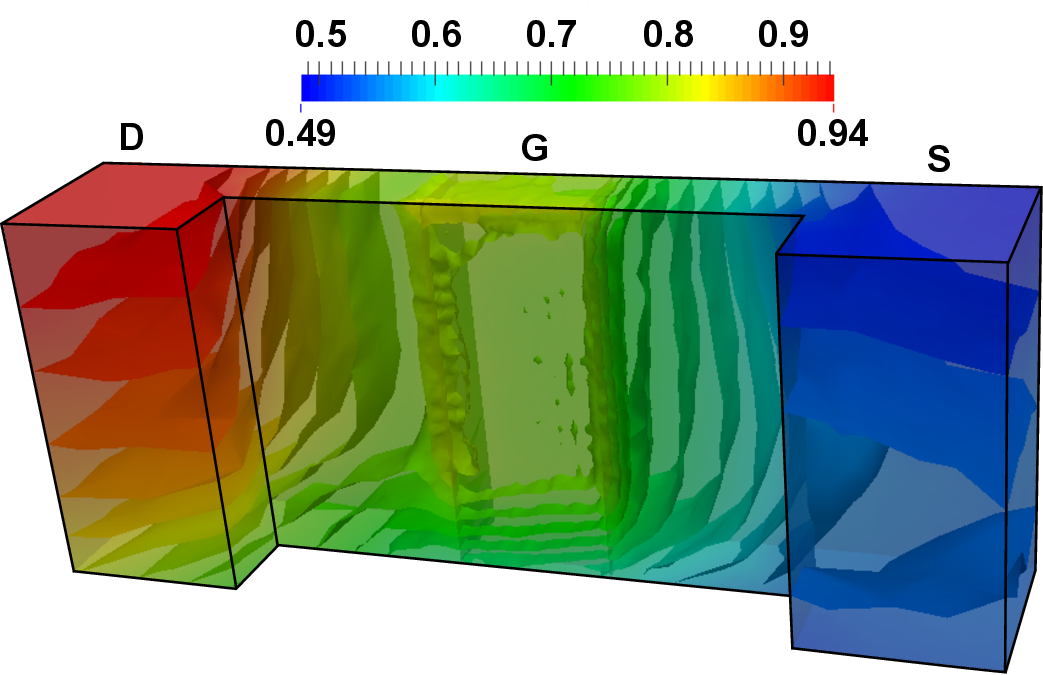

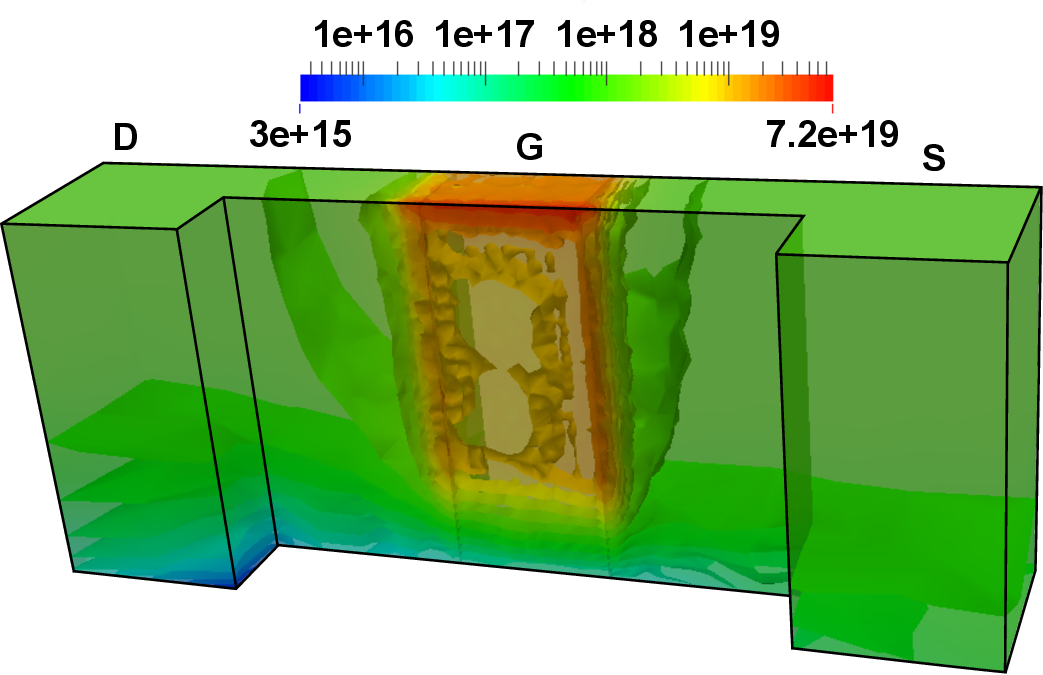

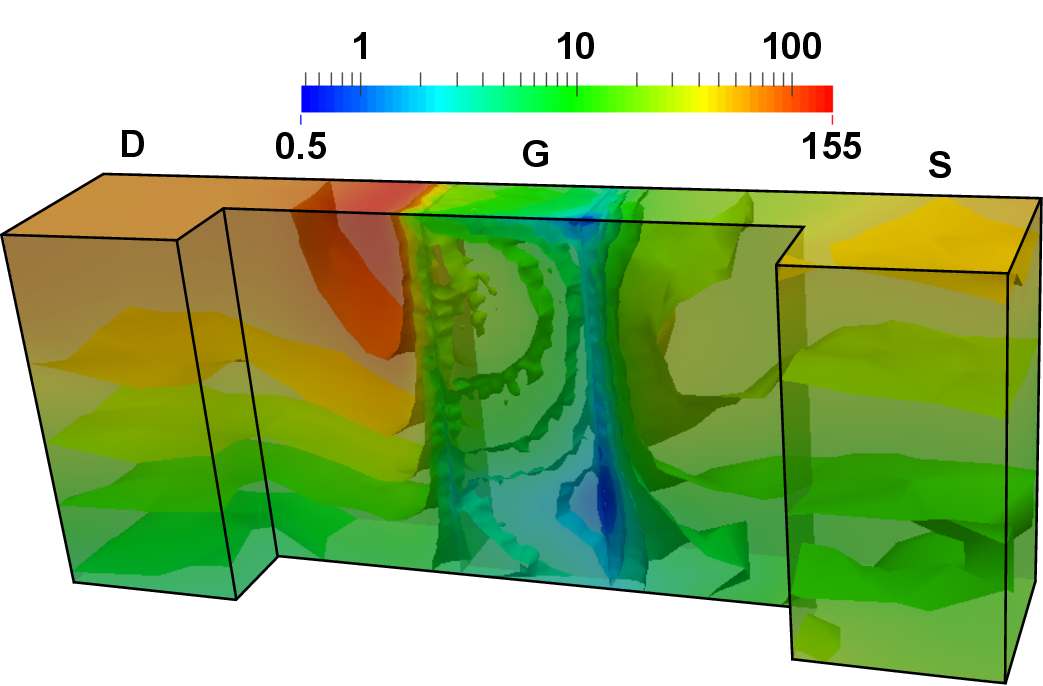

The device has been simulated in its active state, by setting the gate and drain contact

potential to  V as well as the source and bulk contact potential to

V as well as the source and bulk contact potential to  V (Figure 4.23). As

can be seen from the results, the electrons gather primarily under the gate contact, forming a

conducting channel from the source to the drain contact.

V (Figure 4.23). As

can be seen from the results, the electrons gather primarily under the gate contact, forming a

conducting channel from the source to the drain contact.

-Si-SiO

-Si-SiO ) structure,

both assigned as Dirichlet contacts. As the implementation of the Laplace

problem4

keeps the permittivity on the left side of the equation (Section 4.3.6), the potential

reflects the transition between the materials, as shown in Figure 4.16. The potential

drops more significantly in the oxide segments than in the middle semiconductor

segment.

) structure,

both assigned as Dirichlet contacts. As the implementation of the Laplace

problem4

keeps the permittivity on the left side of the equation (Section 4.3.6), the potential

reflects the transition between the materials, as shown in Figure 4.16. The potential

drops more significantly in the oxide segments than in the middle semiconductor

segment.

) of a one-dimensional

capacitor is depicted. Dirichlet boundary conditions have been applied to the left

(

) of a one-dimensional

capacitor is depicted. Dirichlet boundary conditions have been applied to the left

( V) and the right (

V) and the right ( V) metal contact. Note the potential transitions at the material

interfaces due to the different relative permittivities of SiO

V) metal contact. Note the potential transitions at the material

interfaces due to the different relative permittivities of SiO and Si.

and Si.  cm

cm and

and  cm

cm , respectively. The n-Si offers a constant donor

and acceptor doping of

, respectively. The n-Si offers a constant donor

and acceptor doping of  cm

cm and

and  cm

cm , respectively.

, respectively.

V to

V to  V, with a

stepsize of

V, with a

stepsize of  V (Figure

V (Figure  A and

A and  nA is computed, respectively. Figure

nA is computed, respectively. Figure

cm

cm , respectively.

, respectively.

V). For forward bias (positive

potential values) the diode is conductive, whereas for negative bias (negative potential

values) the diode is non-conductive. Note the current saturation (

V). For forward bias (positive

potential values) the diode is conductive, whereas for negative bias (negative potential

values) the diode is non-conductive. Note the current saturation ( V) induced by

high injection effects.

V) induced by

high injection effects.

) in reverse (

) in reverse (

) in reverse (

) in reverse ( cm

cm , whereas the bulk region is set at a constant acceptor doping of

, whereas the bulk region is set at a constant acceptor doping of

cm

cm .

.

V as well as the source and bulk contact potential to

V as well as the source and bulk contact potential to  V (Figure

V (Figure

cm

cm . The bulk (brown) region offers a constant acceptor doping of

. The bulk (brown) region offers a constant acceptor doping of  cm

cm .

.

V, whereas the source and bulk contact

potential is set to

V, whereas the source and bulk contact

potential is set to  V. The contact, oxide, and bulk segments have been removed for

the sake of improved visualization. Iso-surfaces have been added to depict the behavior

in the interior of the device. A conducting channel is formed under the gate as can be

seen from the increased electron concentrations.

V. The contact, oxide, and bulk segments have been removed for

the sake of improved visualization. Iso-surfaces have been added to depict the behavior

in the interior of the device. A conducting channel is formed under the gate as can be

seen from the increased electron concentrations.