12.2 Overview of Topography Simulation

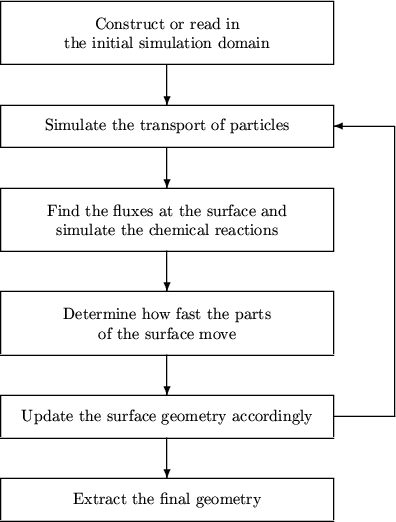

Figure 12.1:

Overview of the general simulation flow of topography

simulations.

|

Before immersing into the details of the simulation, a typical CVD

(chemical vapor deposition) process is discussed [111]. The

chemical reaction can happen in the gas phase, where it is called a

homogeneous reaction, or at the boundary between gas and wafer, where

it is called a heterogeneous reaction. Homogeneous reactions are not

desired in CVD processes since they lead to the formation of clusters

and thus to defects in the film. The heterogeneous reactions,

however, yield high quality films and run selectively in areas where

the temperature is high enough. During heterogeneous reactions the

surface of the substrate often acts as a catalyst. Concerning CVD

processes, the following chemical reactions are discerned: pyrolysis

(heterogeneous decomposition reaction), reduction, oxidation, and

hydrolysis.

The whole deposition or etching process, including the reactor scale

processes which were not considered, can be divided into several

parts.

- Transport of the reactants by convection through the reactor to

the deposition region. The reactants are solved in carrier gas.

This step is governed by the Navier-Stokes equation.

- Transport of the reactants from the convective zone through the

boundary layer to the wafer surface.

- Adsorption of the reactants at the wafer surface.

- Surface reaction: dissociation of the molecules, surface

diffusion of the radicals, incorporation of the radicals in the

solid structure, and formation of byproducts.

- Desorption of the byproducts.

- Transport of the byproducts from the wafer surface through the

boundary layer to the convective zone.

- Transport of the byproducts by convection away from the

features.

Here the boundary layer is the small region above the wafer surface

where the velocity of the flow of the gas is between zero at the

surface and the velocity of the flow in the convective zone.

Operating the equipment the temperature, the pressure and the amount

of species entering the reactor can be adjusted. These three

parameters influence the transport near the wafer surface and the

surface deposition reactions which are discussed in two of the

following sections.

The feature scale simulation of deposition and etching processes can

be divided into three main steps. The according simulation flow of a

typical topography simulation is shown in

Figure 12.1.

- The transport of particles in the boundary layer above the wafer

must be simulated. It can happen in the radiosity or diffusion

regime (cf. Section 12.3).

- The fluxes of particles at the wafer surface found in the

previous step determine the chemical reactions that take place at

the wafer surface (cf. Sections 12.5 and

12.6).

- The surface of the wafer changes according to the previous

steps. Describing the wafer surface and its change due to the

fluxes of etchants and particles to be deposited is an important

part of topography simulations and will be discussed in detail in

Chapter 13.

The rest of this chapter and Chapter 13 are

devoted to the simulation of these main steps. Before we go into

details, we recall some chemical facts.

The coupling between gas concentrations  within the reactor space

and the fluxes

within the reactor space

and the fluxes  towards the surface is given by the relation

towards the surface is given by the relation

|

(12.1) |

Here  is the average molecular velocity of gas species

is the average molecular velocity of gas species  with a molar mass

with a molar mass  .

.

Relating pressure, volume, and temperature, the state equation of the

ideal gas is

where  denotes pressure,

denotes pressure,  volume,

volume,  the number of moles,

the number of moles,

the universal gas

constant and

the universal gas

constant and  absolute temperature. Using

absolute temperature. Using  ,

where

,

where  is the number of molecules and

is the number of molecules and  the Avogadro constant,

and introducing the Boltzmann constant

the Avogadro constant,

and introducing the Boltzmann constant  as

as

, the state

equation can also be written as

where

, the state

equation can also be written as

where

. In the form

. In the form

|

(12.2) |

the state equation relates pressure, temperature, and concentration.

As the unit of pressure,

is usually used by equipment

manufacturers. In SI units this is

is usually used by equipment

manufacturers. In SI units this is

.

.

The classic Langmuir adsorption model [111] describes how gas

adsorption on a solid surface depends on pressure via the equation

, where

, where  is the concentration of adsorbed gas

molecules,

is the concentration of adsorbed gas

molecules,  a constant,

a constant,  the gas fugacity, and

the gas fugacity, and  the

concentration of potential adsorption sites on the surface.

the

concentration of potential adsorption sites on the surface.

Clemens Heitzinger

2003-05-08

![]() within the reactor space

and the fluxes

within the reactor space

and the fluxes ![]() towards the surface is given by the relation

towards the surface is given by the relation

![]() , where

, where ![]() is the concentration of adsorbed gas

molecules,

is the concentration of adsorbed gas

molecules, ![]() a constant,

a constant, ![]() the gas fugacity, and

the gas fugacity, and ![]() the

concentration of potential adsorption sites on the surface.

the

concentration of potential adsorption sites on the surface.