|

|

||||

BiographyAlexander Toifl was born in St. Pölten, Austria, in 1993. He studied at the TU Wien where he received the BSc. degree in Electrical Engineering (2016) and the Diplomingenieur degree in Microelectronics and Photonics (2018). He joined the Institute for Microelectronics in August 2018 as a research assistant. Alex's scientific interests include computational modeling (post-implantation annealing of GaN and SiC) and high performance numerical approaches (non-planar epitaxy) for process TCAD. |

|||||

Continuum Level-Set Model for Anisotropic Wet Etching of Patterned Sapphire Substrates

Anisotropic wet etching of sapphire is characterized by the formation of crystal facets with high Miller-Bravais indices. Consequently, three-dimensional topographies with high complexity emerge during wet etching. These shapes can be utilized to optimize the light extraction efficiency of GaN-based light-emitting diodes. Since sapphire topography significantly affects the light extraction efficiency of the final device, precise control over the wet etching process, in particular etchant mixture, etch time and temperature, is highly important.

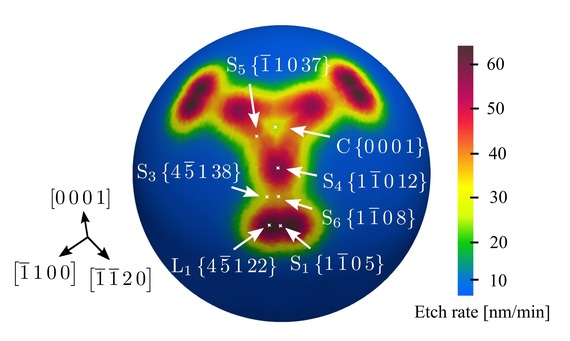

We have proposed a continuum model in the context of process technology computer-aided design (TCAD), where we use the level-set method to track the evolution of the three-dimensional etch profile over time. In order to describe the intricate anisotropy of wet etched sapphire, we have devised a flexible interpolation method for the orientation-dependent etch rate. This method incorporates experimentally characterized crystal facets and deduces local extrema in the etch rate distribution based on local convexity considerations. Furthermore, the crystal symmetry, which is trigonal in the case of sapphire, must be respected. Hence, a procedure that maps all possible crystal orientations to their crystallographically equivalent directions has been developed. The fundamental domain of the associated point group is identified, and a series of symmetry operations is performed (e.g. rotations and reflections at mirror planes). Fig. 1 illustrates the resulting etch rate distribution, which reflects the trigonal symmetry. In particular, the distribution is more intricate than the etch anisotropy observed with potassium hydroxide (KOH) etched silicon.

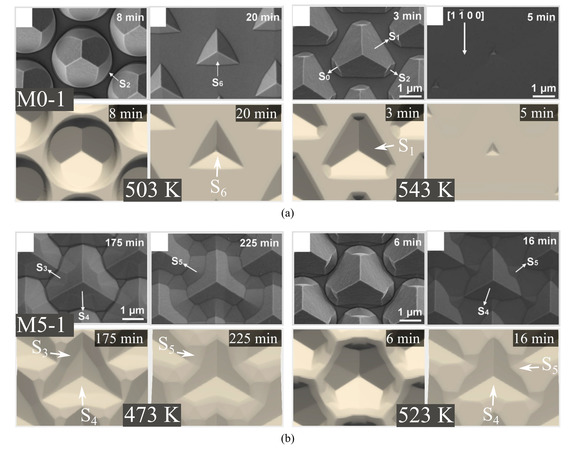

The model has been calibrated and evaluated based on scanning electron microscopy and atomic force microscopy characterizations from the literature. Our model enables accurate sapphire etching simulations, where the emerging and disappearing crystal facets show good agreement with experimental observations for several etchant mixtures and temperatures. In Fig. 2, a comparison of experimental (top rows) and simulation results (bottom rows) is shown. The characteristic topography features are well resolved for the entire etch profile evolution. Furthermore, the temperature dependence of the etch rate distribution has been investigated, and Arrhenius laws for the individual etch rate coefficients have been established. As a result, the model is applicable for a broad range of etchants and etch temperatures.

[1] A Toifl et al 2021 Semicond. Sci. Technol. 36 045016, doi: 10.1088/1361-6641/abe49b

Fig. 1: Sapphire displays an intricate wet etch anisotropy when etched with mixtures of sulfuric and phosphoric acid. Originally published under Creative Commons Attribution 4.0 License in [1] (Fig. 3).

Fig. 2: Comparison of experimental (top rows) and simulation results (bottom rows) for different etch temperatures, times and etchant mixtures. MX-Y denotes a volume ratio of sulfuric acid: phosphorous acid = X:Y. Originally published under Creative Commons Attribution 4.0 License in [1] (Fig. 8).