in Fig. 4.9 is bound between

in Fig. 4.9 is bound between  (the

extrapolated ‘true’ degradation) and

(the

extrapolated ‘true’ degradation) and  . The larger the delay time, the closer

. The larger the delay time, the closer

and

and  get and vice versa.

get and vice versa.

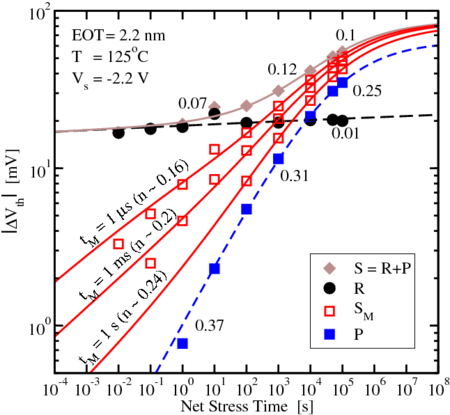

Based on the extracted model parameters of (4.5), a correlation between the

observed degradation and the measurement delay can be obtained. The actually

observable data marked with  in Fig. 4.9 is bound between

in Fig. 4.9 is bound between  (the

extrapolated ‘true’ degradation) and

(the

extrapolated ‘true’ degradation) and  . The larger the delay time, the closer

. The larger the delay time, the closer

and

and  get and vice versa.

get and vice versa.

and

and  , lines:

model). The measurement results (

, lines:

model). The measurement results ( ) lie between

) lie between  and

and  . Depending

on the measurement delay of the equipment (

. Depending

on the measurement delay of the equipment ( ) a broad range of ‘effective’

power-law slopes are observed (limiting values given next to the model lines).

) a broad range of ‘effective’

power-law slopes are observed (limiting values given next to the model lines).

When fitting the single stress sequences with varying  by a power-law,

different values of the slope are obtained which may be a reason why the

power-law exponents reported in NBTI literature vary that strongly. In

Fig. 4.10 the power-law slopes, defined as

by a power-law,

different values of the slope are obtained which may be a reason why the

power-law exponents reported in NBTI literature vary that strongly. In

Fig. 4.10 the power-law slopes, defined as  , are

shown. As can be seen the extrapolation with a power-law does not seem

to be the best choice to represent the time behavior of NBTI due to

the interplay between

, are

shown. As can be seen the extrapolation with a power-law does not seem

to be the best choice to represent the time behavior of NBTI due to

the interplay between  and

and  . Since the power-law extrapolation is

furthermore only approximately valid over a few decades in time, lifetime

prediction based on this approximate concept should be done with great

care.

. Since the power-law extrapolation is

furthermore only approximately valid over a few decades in time, lifetime

prediction based on this approximate concept should be done with great

care.

and

and  , lines:

model). The effective power-law slope as a function of the measurement

delay, defined as

, lines:

model). The effective power-law slope as a function of the measurement

delay, defined as  is only approximately valid over a

few decades in time within the standard measurement window. This is due

to the interaction between

is only approximately valid over a

few decades in time within the standard measurement window. This is due

to the interaction between  (depending on the measurement delay) and

(depending on the measurement delay) and

(indepenent of

(indepenent of  ).

).