In this section, two representative application examples are discussed based on two ViennaMOS modules. The general design and usage of the modules is depicted as well as the basic utilization of the ViennaMOS GUI and visualization backends. More concretely, the already mentioned device generation module is introduced which provides different ways to generate a simulation domain. Upon the module’s execution, the generated device is stored in the central database. The second module, a device simulation module based on the previously introduced device simulation framework ViennaMini (Section 4.3), utilizes the device generated by the device generation module to conduct a device simulation.

These examples further underline the advantages of the decoupled approach discussed throughout this thesis as depicted in Figure 6.1. Not only libraries are reused by the individual modules, but also another framework - ViennaMini - is utilized via ViennaMOS modules. Therefore, additional development overhead is drastically minimized, as already available implementations, such as mesh generation or device simulation facilities, are reused.

In this section a device generation module is discussed providing the means to generate devices for device simulations via the ViennaMini framework (Section 4.3.3). This example also underlines the versatility of ViennaMOS modules, as this particular module is in fact not a simulation module, but a modeling tool required to characterize the simulation domain. To this end, the module requires mesh generation capabilities and the ability to assign a doping profile and segment roles. Overall, the module utilizes the various device generation functionalities enabled by interfacing with external tools, such as ViennaMini, and provides a flexible GUI for the process, further underlining the benefit of rigorously applying a LCSD approach.

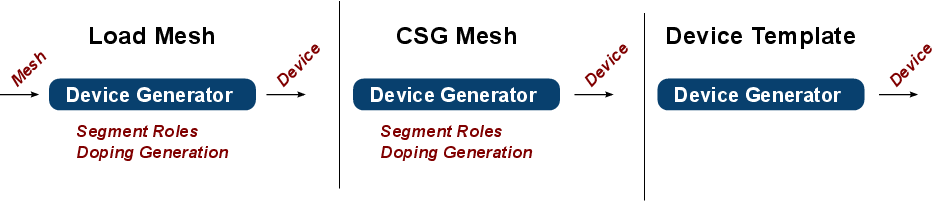

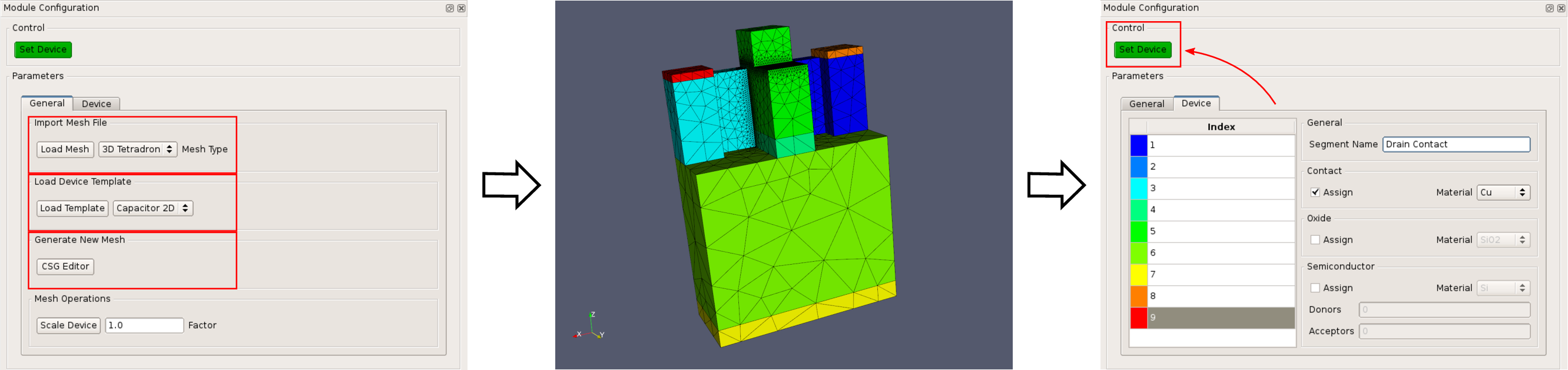

The device generation module provides three mechanisms to generate a device. Where the first mode loads an externally generated already meshed structure enabling the end user to assign segment roles as well as a doping profile, the second mode allows to perform an in-place mesh generation for a desired device structure via a constructive solid geometry ( CSG) language (primarily of interest to advanced users) also requiring the end user to provide segment roles as well as doping information. The third mode utilizes a device template mechanism, already providing default segment and doping information. Figure 6.17 schematically depicts the individual device generation modes.

Figure 6.18 depicts the module’s GUI and the basic process flow. The end user selects one of the three device generation mechanisms. As soon as the structure is loaded, the render window visualizes the mesh. Finally the GUI provides the means to assign segment roles including doping levels for semiconductor segments. When the end user is finished, the device can be stored into ViennaMOS’ central data storage, so other modules can access it. In this particular case, a FinFET device is prepared, offering the same properties as depicted in Section 4.3.10. This device is used in the subsequent device simulation steps, therefore it is stored in the central database.

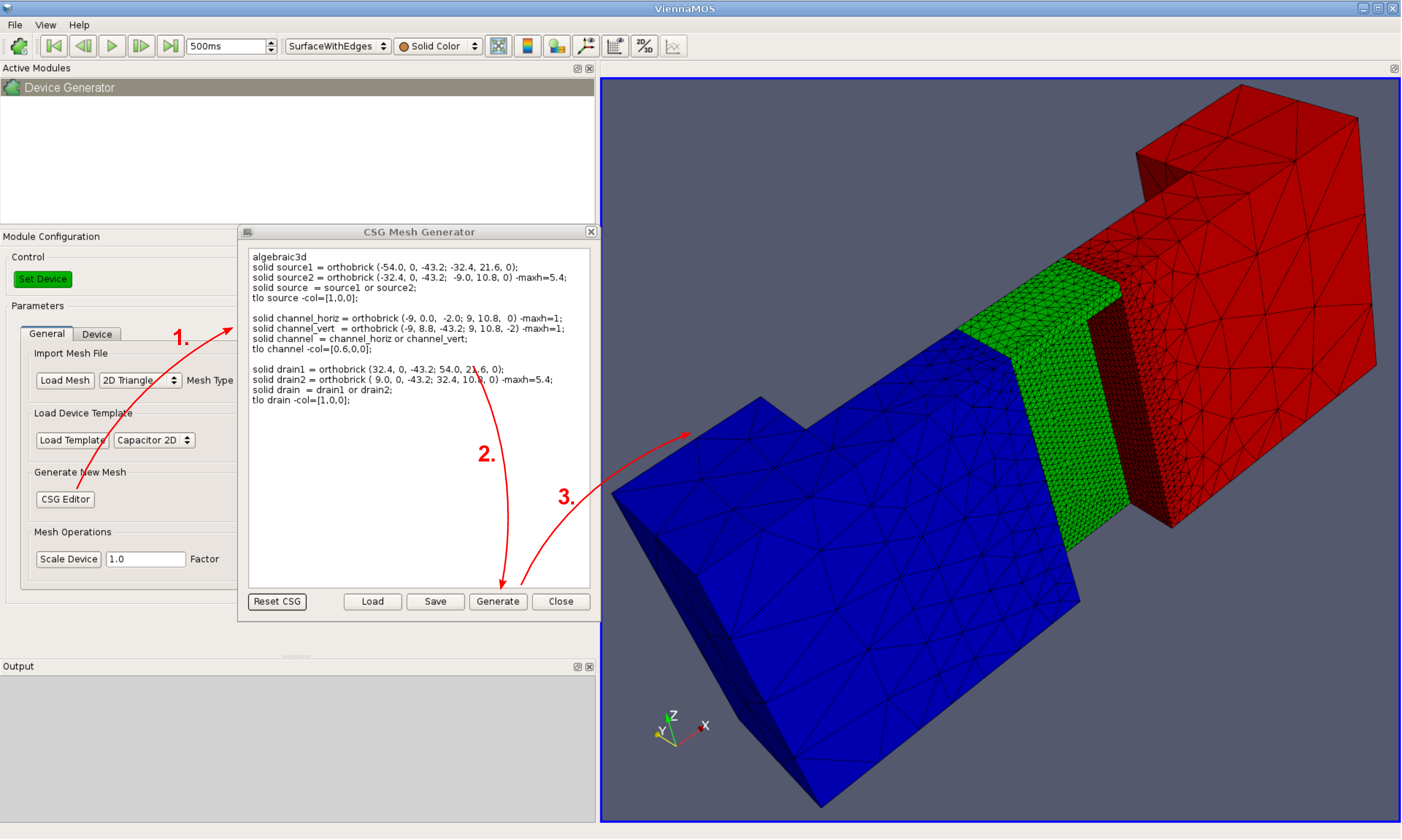

Aside from the already discussed structure loading and device template mechanism, a peculiarity of this module is the CSG functionality. ViennaMesh provides an interface to Netgen’s three-dimensional CSG backend, enabling on-the-fly generations of meshed structures inside the device generation module. Due to the applied LCSD approach, the module’s GUI has to provide merely a text input field - holding the CSG commands - which is forwarded to the CSG backend via ViennaMesh.

In turn, ViennaMesh takes care of transferring the generated mesh into an appropriate ViennaGrid mesh object. Figure 6.19 depicts the utilization of the CSG mechanism.

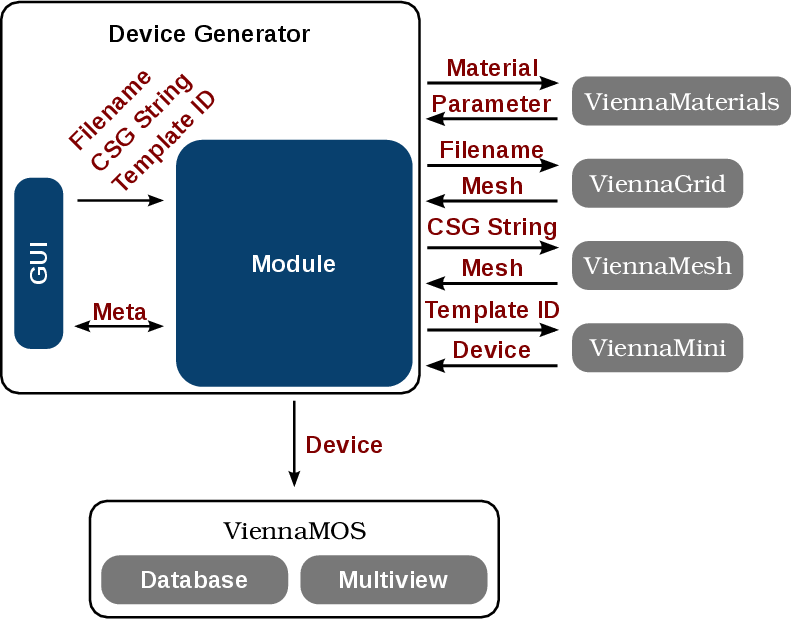

The implementation of the device generation module is based on two classes, separating the GUI from the actual module implementation interfacing with external libraries (Figure 6.20). The GUI forwards the input data to the module according to the chosen generation mode. For instance, if the CSG mode is used, a string containing the CSG information is passed. The module makes use of synergy effects in particular by interfacing with ViennaGrid, ViennaMesh, ViennaMini, and ViennaMaterials for loading and generating meshes, accessing material data as well as using the device template mechanism, respectively. The thus received data is used to update the GUI, allowing the end user to customize the device by, for instance, updating the segment roles and doping information. Finally, if the end user is finished, the device is forwarded to the framework, where it is stored in the central database for other modules to access it.

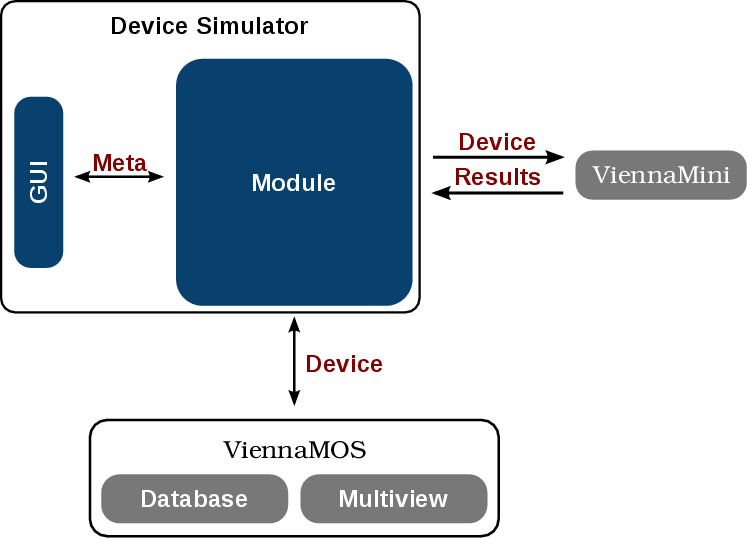

This section introduces a device simulation module providing basic device simulation capabilities. The module is a wrapper for the previously introduced device simulation framework ViennaMini (Section 4.3), further underlining the benefit of decoupling functionality into reusable tools by the LCSD approach. Also, the fact that this module is merely a wrapper puts the focus of this section on the module itself rather than discussions regarding the simulation results.

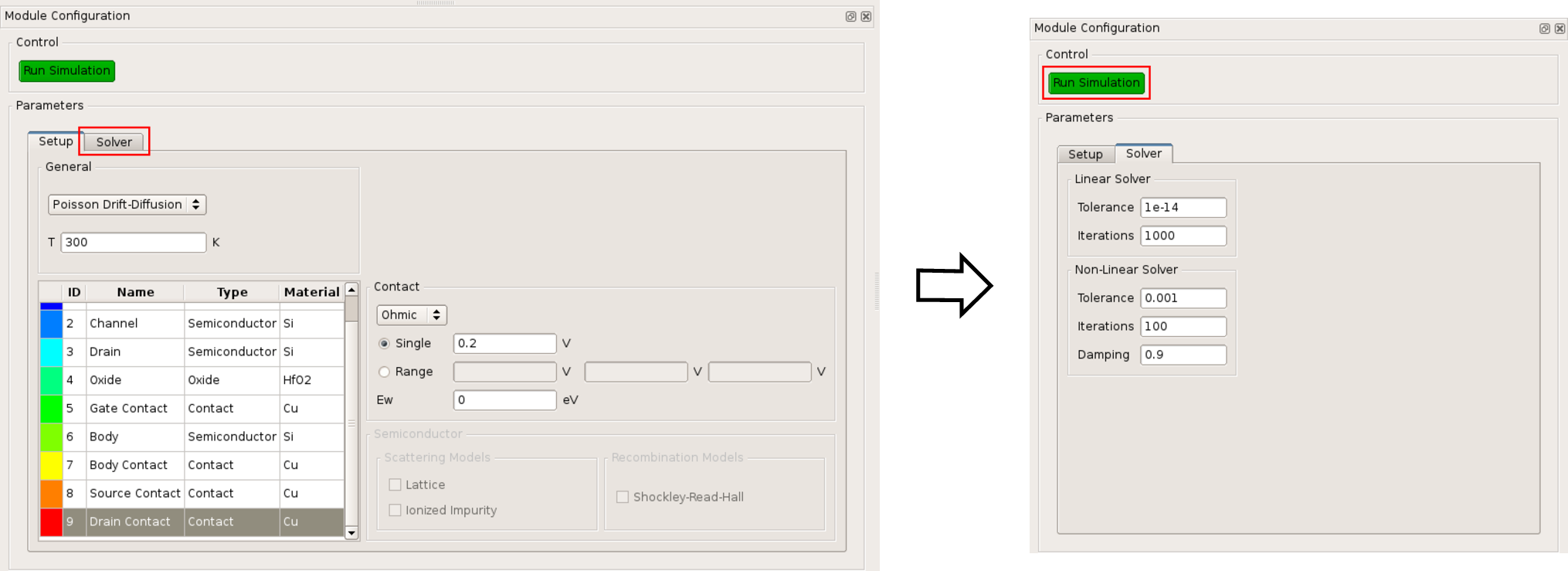

With respect to the implementation, the device simulator module interfaces with ViennaMini and provides a GUI for the provided API (Figure 6.21). The device simulation module becomes usable, i.e., it can be selected in the active module list of the main ViennaMOS GUI (Section 6.2.6), as soon as a valid device is stored in the ViennaMOS central data storage. The device is automatically imported and the GUI is updated accordingly, enabling the end user to setup contact potentials or currents as well as particular physical models. Upon the module’s execution the ViennaMini-powered simulation is conducted.

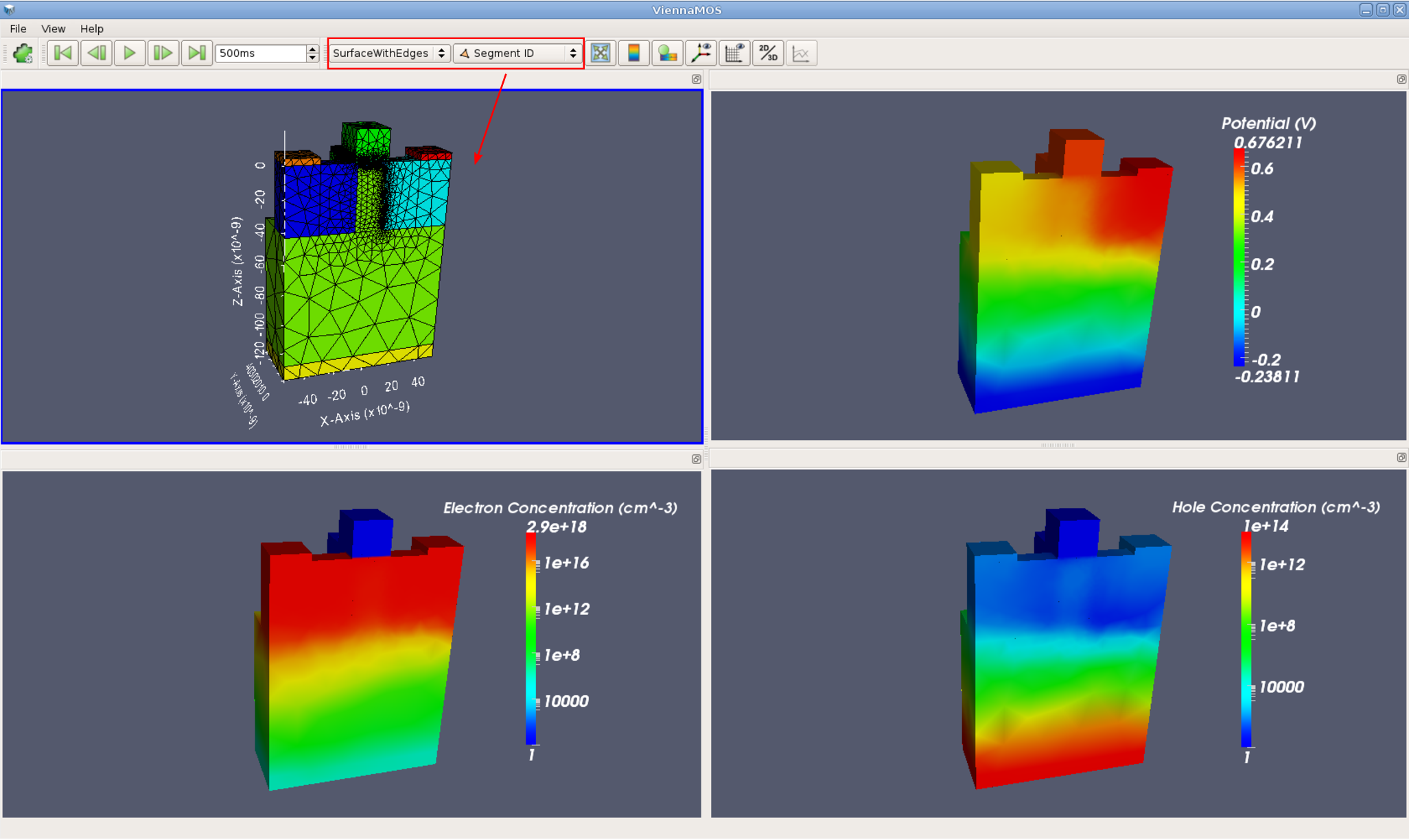

Figure 6.22 shows a basic but representative populated device simulation GUI based on the FinFET device generated by the previously executed device generation module. The GUI provides an overview of the device segments and related meta information, generated by the previously utilized device generation module. The device simulation setup is segment-based, meaning that the end user can assign contact potentials and semiconductor models, like scattering models, for each segment. The actual simulation is triggered via the corresponding execution button. When the simulation is finished, the results can be visualized by ViennaMOS’ multiview mechanism (Figure 6.23). In this particular case a similar simulation - an active FinFET device - as introduced in Section 4.3.10 has been conducted. Note that the current limitations of the visualization mechanism do not allow for manual color ranges, therefore if logarithmic color rendering is required - as is the case for the electron concentration and hole concentration distributions - segments offering no quantity values are automatically assigned a value of one to enable the computation of the logarithm. This manifests with the carrier concentration distributions’ renderings where the gate is assigned a value of one.