Next: 3. The Silicon/Silicon-Dioxide Interface

Up: 2. Simulation of Semiconductor

Previous: 2.3 Carrier Generation and

Subsections

The classical semiconductor device equations from Section 2.1

imply that the mobile carriers, electrons and holes, behave like classical

particles in the semiconductor. For large device dimensions this assumption

gives very good results, but for small device geometries quantum mechanical

effects like the quantum mechanical tunneling, described in Section 5.3,

and the quantum mechanical confinement gain importance. The latter effect

leads to a reduction of allowed states for electrons and holes near a

interface. In classical device simulations using the drift-diffusion

approximation the peak of the electron concentration in the channel of a turned

on n-channel MOSFET is calculated to be directly at the

interface. In classical device simulations using the drift-diffusion

approximation the peak of the electron concentration in the channel of a turned

on n-channel MOSFET is calculated to be directly at the

interface.

This is not correct as the number of allowed states is drastically reduced

close to the interface and therefore the peak of the carrier concentration lies

several angstroms away from the interface [9].

interface.

This is not correct as the number of allowed states is drastically reduced

close to the interface and therefore the peak of the carrier concentration lies

several angstroms away from the interface [9].

2.4.1 Quantum Confinement

For the modeling of NBTI the carrier concentration close to the

interface plays an important role (Section 6.4.4). The use

of quantum confinement models reduces this carrier concentration and might have

significant influence on the NBTI model used.

interface plays an important role (Section 6.4.4). The use

of quantum confinement models reduces this carrier concentration and might have

significant influence on the NBTI model used.

In classical device simulators quantum confinement is often accounted for by

using additional quantum correction models. These models locally change the

carrier density-of-states [10,11] or they modify the

conduction band edge close to the interface [12].

In classical device simulation the density-of-states (DOS) in homogeneous

materials is modeled as a constant value throughout the device. In order to

describe the quantum mechanical confinement a distance-dependent reduction of

the DOS at the

interface has been proposed

in [10,11]

interface has been proposed

in [10,11]

|

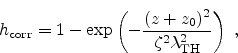

(2.106) |

where  is the distance to the

is the distance to the

interface and

interface and  shifts the whole

function relative to the interface.

shifts the whole

function relative to the interface.  is a newly introduced parameter

which enables the variation of

is a newly introduced parameter

which enables the variation of

for calibration

purposes. The symbol

for calibration

purposes. The symbol

denotes the thermal wavelength which

is given by

denotes the thermal wavelength which

is given by

|

(2.107) |

where  is the reduced Planck constant,

is the reduced Planck constant,  is the effective carrier

mass,

is the effective carrier

mass,

the Boltzmann constant, and

the Boltzmann constant, and  the temperature. The resulting

DOS,

the temperature. The resulting

DOS,  , is then calculated from the classical DOS

, is then calculated from the classical DOS

, which is normally modeled as a constant throughout the

semiconductor, with the correction factor

, which is normally modeled as a constant throughout the

semiconductor, with the correction factor

as

as

|

(2.108) |

Figure 2.5:

Plot of the DOS correction factor

for

for  nm

and

nm

and  at

at  K.

K.

|

|

The interplay of the different parameters and the distance to the

interface is schematically depicted in Figure 2.5. The parameter

interface is schematically depicted in Figure 2.5. The parameter

is important, because with

is important, because with  the DOS at the interface becomes zero.

This would cause numerical problems and reduce the convergence of the numerical

solver. A positive number of

the DOS at the interface becomes zero.

This would cause numerical problems and reduce the convergence of the numerical

solver. A positive number of  shifts the correction function towards the

dielectric, approximately considering wave function penetration. The value of

shifts the correction function towards the

dielectric, approximately considering wave function penetration. The value of

defines the effective depth of the correction. A

high value, which can be achieved with

defines the effective depth of the correction. A

high value, which can be achieved with  , leads to a reduction of the

DOS even deep in the substrate.

, leads to a reduction of the

DOS even deep in the substrate.

Note that the correction factor does not depend on the bias and the band edge

energies are not influenced. Hence, the model can be evaluated in a

preprocessing step and does not impose any additional computational burden

during iteration steps.

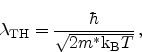

Figure 2.6:

Band edge bending at the

interface. The classical band edge

is corrected by the factor

interface. The classical band edge

is corrected by the factor

.

.

|

|

An alternative approach is based on  , the first eigenvalue of the

triangular energy well, as seen in Figure 2.6. This model was proposed by

van Dort [12]

, the first eigenvalue of the

triangular energy well, as seen in Figure 2.6. This model was proposed by

van Dort [12]

|

(2.109) |

where the proportionality factor

is

is found from the observed threshold voltage shift at high doping

levels [13],

is

is found from the observed threshold voltage shift at high doping

levels [13],

is the permittivity of

silicon, and

is the permittivity of

silicon, and  is the electric field at the

is the electric field at the

interface

perpendicular to the interface.

interface

perpendicular to the interface.

The value of

is multiplied with a distance-dependent

weight function which has been introduced by Selberherr [14] for

the modeling of surface roughness scattering in MOSFETs. The function is of the

following form

is multiplied with a distance-dependent

weight function which has been introduced by Selberherr [14] for

the modeling of surface roughness scattering in MOSFETs. The function is of the

following form

|

(2.110) |

where

is the scaling factor for the interface distance. Thus,

the resulting band edge energy with van Dort's quantum correction of the

classical band edge energy

is the scaling factor for the interface distance. Thus,

the resulting band edge energy with van Dort's quantum correction of the

classical band edge energy

reads as follows

reads as follows

|

(2.111) |

Figure 2.6 depicts the distance dependent weight function  and the band

edge energy for both, the classical approach and after quantum correction with

van Dort's method.

and the band

edge energy for both, the classical approach and after quantum correction with

van Dort's method.

For the evaluation of the quantum correction models a state-of-the-art

three-dimensional n-channel FinFET device structure was chosen. The device

geometry can be seen in Figure 2.7.

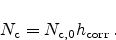

Figure 2.7:

Device geometry of a triple-gate FinFET structure. Quantum

confinement plays an important role in this device because of its small size

and the formation of three, instead of one, channels.

|

|

The silicon fin has a cross section area of 6 10nm

10nm . The gate

length is 20nm with a gate oxide thickness of 1.5nm. The source and drain

regions are heavily n-type doped whereas the channel itself remains undoped.

. The gate

length is 20nm with a gate oxide thickness of 1.5nm. The source and drain

regions are heavily n-type doped whereas the channel itself remains undoped.

Figure 2.8:

Electron concentration in a triple-gate FinFET for classical

simulation (left), with the DOS correction model (middle), and the band edge

energy correction model by Van Dort. The correction models force the peak of

the carrier concentration away from the

interface into the

substrate.

interface into the

substrate.

|

|

Figure 2.8 depicts the electron concentration in a two-dimensional cut

through the silicon fin in the middle of the channels. The gates are biased at

0.9V with the source and drain contacts grounded. The classical simulation

using the drift-diffusion approximation gives the highest magnitude of the

electron concentration at the

interfaces below the gate contacts. It

can be seen that the peak electron concentration is found in the top corners,

as two respective gates couple to the channel, each of them attracting

carriers. With the quantum confinement correction models the maximum carrier

concentration is moved to the inside of the fin by a distance depending on the

chosen model and its calibration parameters.

interfaces below the gate contacts. It

can be seen that the peak electron concentration is found in the top corners,

as two respective gates couple to the channel, each of them attracting

carriers. With the quantum confinement correction models the maximum carrier

concentration is moved to the inside of the fin by a distance depending on the

chosen model and its calibration parameters.

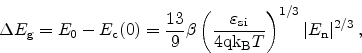

Figure 2.9:

Electron concentration across the fin using classical device

simulation and the confinement correction models.

|

|

Figure 2.9 depicts a one-dimensional cut through the fin displaying the

carrier concentrations for the different models for the same bias conditions.

Comparing with Figure 2.10 reveals that qualitatively the DOS correction

model delivers better results.

Figure 2.10:

Comparison of classical and quantum mechanical carrier

concentrations for different fin widths. The quantum mechanical calculations

have been performed using a Schrödinger solver.

|

|

A comparison of FinFETs with different fin widths can be seen in

Figure 2.10. It shows the electron concentration across the fin

simulated with both, the classical drift-diffusion model and a Schrödinger

solver, respectively. The fin widths are 6, 12, and 18nm. At a fin width of

6nm the electron concentration has its maximum in the center of the fin. This

shape of the carrier concentration cannot be reproduced by the quantum

correction models. With larger widths the maximum moves to the interfaces

enabling a better fit of the correction models.

Figure 2.11:

Comparison of the output characteristics of double- and triple-gate

FinFETs at a gate voltage of 0.9 V. Quantum confinement correction

reduces the drain current as no carriers are allowed at the

interface.

interface.

|

|

The channels in the silicon fin are displaced from the surface to the inside of

the silicon and thus the drive current is reduced. Figure 2.11 depicts

the drain current for a gate voltage of 0.9V and different quantum correction

mechanisms. Additionally to the triple-gate device the simulation has been

performed with a double-gate structure, where the top gate from Figure 2.7

has been replaced with

. Simulation of the double-gate structure shows a

reduced output current by a factor of approximately 20% due to the formation

of only two channels.

. Simulation of the double-gate structure shows a

reduced output current by a factor of approximately 20% due to the formation

of only two channels.

Quantum correction leads to a considerable reduction of the saturation current.

The DOS correction model yields reasonable results, but since it does not

account for the band bending it must be calibrated for each bias point. Van

Dort's model completely fails to reproduce the carrier concentration in the

channel which may be due to the assumption of a triangular energy well. This

assumption might be a too crude estimation for extremely thin channels.

Therefore, these models can be very well used to describe the current reduction

in very thin channel devices, but not when the shape of the carrier

concentration is important. Here, the solution of Schrödinger's equation is

necessary for accurate simulation of the carrier concentration.

Next: 3. The Silicon/Silicon-Dioxide Interface

Up: 2. Simulation of Semiconductor

Previous: 2.3 Carrier Generation and

R. Entner: Modeling and Simulation of Negative Bias Temperature Instability

![]() interface is schematically depicted in Figure 2.5. The parameter

interface is schematically depicted in Figure 2.5. The parameter

![]() is important, because with

is important, because with ![]() the DOS at the interface becomes zero.

This would cause numerical problems and reduce the convergence of the numerical

solver. A positive number of

the DOS at the interface becomes zero.

This would cause numerical problems and reduce the convergence of the numerical

solver. A positive number of ![]() shifts the correction function towards the

dielectric, approximately considering wave function penetration. The value of

shifts the correction function towards the

dielectric, approximately considering wave function penetration. The value of

![]() defines the effective depth of the correction. A

high value, which can be achieved with

defines the effective depth of the correction. A

high value, which can be achieved with ![]() , leads to a reduction of the

DOS even deep in the substrate.

, leads to a reduction of the

DOS even deep in the substrate.

![\includegraphics[width=10cm]{figures/vandort}](img300.png)

![]() is multiplied with a distance-dependent

weight function which has been introduced by Selberherr [14] for

the modeling of surface roughness scattering in MOSFETs. The function is of the

following form

is multiplied with a distance-dependent

weight function which has been introduced by Selberherr [14] for

the modeling of surface roughness scattering in MOSFETs. The function is of the

following form

![]() and the band

edge energy for both, the classical approach and after quantum correction with

van Dort's method.

and the band

edge energy for both, the classical approach and after quantum correction with

van Dort's method.

![\includegraphics[width=10cm]{figures/finfet}](img312.png)

![\includegraphics[width=16cm]{figures/cut-econcentrations}](img315.png)

![]() interfaces below the gate contacts. It

can be seen that the peak electron concentration is found in the top corners,

as two respective gates couple to the channel, each of them attracting

carriers. With the quantum confinement correction models the maximum carrier

concentration is moved to the inside of the fin by a distance depending on the

chosen model and its calibration parameters.

interfaces below the gate contacts. It

can be seen that the peak electron concentration is found in the top corners,

as two respective gates couple to the channel, each of them attracting

carriers. With the quantum confinement correction models the maximum carrier

concentration is moved to the inside of the fin by a distance depending on the

chosen model and its calibration parameters.

![\includegraphics[width=\figwidth]{figures/econc_rot}](img316.png)

![\includegraphics[width=\figwidth]{figures/qmclassic_rot}](img317.png)

![\includegraphics[width=\figwidth]{figures/outputchar-color}](img318.png)