Next: 6.5 Tsetseris' Model

Up: 6. Negative Bias Temperature

Previous: 6.3 Physical Mechanisms of

Subsections

6.4 Reaction-Diffusion Model

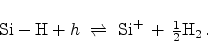

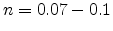

Figure 6.10:

Schematic representation of the reaction-diffusion (R-D) model.

Electrically inactive Si-H bonds at the

interface are broken and the

hydrogen diffuses into the dielectric leaving behind an electrically active

interface trap

interface are broken and the

hydrogen diffuses into the dielectric leaving behind an electrically active

interface trap

. Here, H

. Here, H diffusion is assumed.

diffusion is assumed.

|

|

The reaction-diffusion (R-D) model is pioneering for the description of NBTI.

It was first proposed by Jeppson and Svensson in 1977 [103] and is

capable of reproducing the time evolution of device degradation due to negative

bias temperature stress for a wide range of measurements.

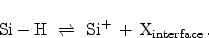

The model describes the device degradation as a combination of two effects. In

the first place, a field-dependent electrochemical reaction at the

interface. Electrically inactive, passivated silicon dangling bonds

(Section 3.1), Si-H, are broken. Here an electrically

active interface state

interface. Electrically inactive, passivated silicon dangling bonds

(Section 3.1), Si-H, are broken. Here an electrically

active interface state

and a mobile, hydrogen related species

and a mobile, hydrogen related species

are

formed,

are

formed,

|

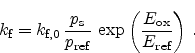

(6.5) |

In the second place, the model describes the transport of the hydrogen species

away from the interface into the dielectric,

|

(6.6) |

Also the reverse process is possible: transport of a diffusing hydrogen species

back to the interface and re-passivation of a

dangling bond.

dangling bond.

Figure 6.10 gives a schematic illustration of the model. In the

figure hydrogen molecules,

, are assumed as the diffusing species. The

process at the interface is modeled by a rate equation as

, are assumed as the diffusing species. The

process at the interface is modeled by a rate equation as

|

(6.7) |

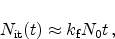

where

is the interface-trap generation and

is the interface-trap generation and

the annealing rate. The

symbol

the annealing rate. The

symbol

denotes the initial number of electrically inactive Si-H bonds and

denotes the initial number of electrically inactive Si-H bonds and

is the surface concentration of the diffusing species. The value of

is the surface concentration of the diffusing species. The value of

gives the order of the reaction. In the original publication, neutral

hydrogen, H

gives the order of the reaction. In the original publication, neutral

hydrogen, H , was proposed [103] which is obtained with

, was proposed [103] which is obtained with  .

For molecular hydrogen,

.

For molecular hydrogen,

,

,  . In this case the molecule is assumed

to be formed in the vicinity of the interface

. In this case the molecule is assumed

to be formed in the vicinity of the interface

|

(6.8) |

The Si-H bond is broken and captures a hole, leading to a positively charged

interface state and molecular hydrogen is formed.

The equilibrium of the forward and backward reaction is controlled by the

hydrogen density at the interface

. Thus, the transport mechanism of

the hydrogen species away from the interface characterizes the degradation

mechanism, controlling the device parameter shift. The original

reaction-diffusion model describes the transport as a purely diffusive

mechanism which is described by the diffusion equation

. Thus, the transport mechanism of

the hydrogen species away from the interface characterizes the degradation

mechanism, controlling the device parameter shift. The original

reaction-diffusion model describes the transport as a purely diffusive

mechanism which is described by the diffusion equation

|

(6.9) |

Here,  is the diffusivity of the hydrogen species in the dielectric. The

influx of the newly created species has to be considered as

is the diffusivity of the hydrogen species in the dielectric. The

influx of the newly created species has to be considered as

|

(6.10) |

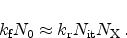

For each generated interface trap a hydrogen is released, thus

|

(6.11) |

The R-D model assumes the interface states to be the only contribution to

device parameter shift. But especially thick high-voltage oxides also show the

generation of oxide charges due to hole trapping [86], leading to an

additional parameter shift. Therefore it has been suggested [85] to

separate the oxide charge contribution from the measurement results, before the

R-D model can put into agreement to them. Suggested methods are the estimation

of bulk-trap concentration for every stress voltage, temperature, and oxide

thickness or trying to avoid the generation of bulk-traps by optimizing the

stress conditions to that aspect.

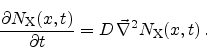

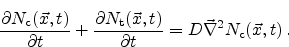

Figure 6.11:

The five different regimes for the time exponent  , as obtained

from the reaction-diffusion model.

, as obtained

from the reaction-diffusion model.

|

|

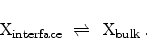

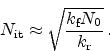

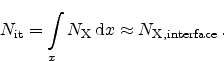

For the stress phase the solution of the R-D model can be split up into five

different regimes. They are distinguished by different time exponents  (Section 6.2) for the degradation and are depicted in

Figure 6.11.

(Section 6.2) for the degradation and are depicted in

Figure 6.11.

In the very early stage of the stress phase the amount of free hydrogen, both,

at the interface and in the dielectric

is very low. The amount of

already broken Si-H bonds at the interface

is very low. The amount of

already broken Si-H bonds at the interface

is close to zero. Thus,

Equation 6.7 is solely limited by the forward reaction rate

is close to zero. Thus,

Equation 6.7 is solely limited by the forward reaction rate

and

transforms to

and

transforms to

|

(6.12) |

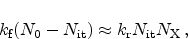

with the solution for the interface trap generation

|

(6.13) |

when assuming

|

(6.14) |

having a time dependence of  .

.

After some time, when the amount of hydrogen at the interface is considerable,

the forward reaction reaches a quasi-equilibrium with the backward reaction

|

(6.15) |

and, as

is very large with respect to

is very large with respect to

|

(6.16) |

The diffusion process has not removed a considerable amount of hydrogen from

the interface yet, therefore the amount of interface traps equals the amount of

hydrogen at the interface

|

(6.17) |

We therefore get

|

(6.18) |

As this equation is not time dependent we can write

|

(6.19) |

with a resulting time dependence of  .

.

As long as the diffusion of hydrogen away from the interface has not reached a

considerable magnitude, there is no further degradation of the interface.

Regime three starts when the diffusion of hydrogen away from the interface sets

in and acts as limiting factor for the degradation. In this phase the

diffusion front has not reached the poly gate, therefore

|

(6.20) |

An analytical solution has been found to be [103]

|

(6.21) |

Numerically the solution is, depending on the group, somewhat

larger [85] or smaller [104] then the analytical

solution of  as it is based on some simplifications.

as it is based on some simplifications.

In the reaction-diffusion model, this is the dominating regime in the typical

lifetime of a MOSFET. It sets in after some seconds stress and, depending on

the exact conditions, is dominating for several orders of magnitude in time,

lasting up to several years.

When the diffusion front reaches the poly gate contact the time exponent

changes again. In the model it is assumed that the gate electrode acts as

absorber for the diffusing species or, in other words, the diffusivity is

significantly higher in the poly than in the dielectric. For this case a time

exponent of  is derived. Although a slight increase of the time

exponent can be found in some measurement data for thin dielectrics, it is way

below

is derived. Although a slight increase of the time

exponent can be found in some measurement data for thin dielectrics, it is way

below  .

.

When, theoretically, all interface bonds

are broken and

are broken and

|

(6.22) |

no further degradation can occur in this model. Therefore the change in

is zero and so is the time exponent

is zero and so is the time exponent  . As this saturation condition would

only occur ever at extremely long stress times, or, at very high stress

conditions which would lead to other degradation mechanisms as TDDB

(Section 5.2), it has not yet been observed experimentally.

. As this saturation condition would

only occur ever at extremely long stress times, or, at very high stress

conditions which would lead to other degradation mechanisms as TDDB

(Section 5.2), it has not yet been observed experimentally.

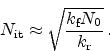

It has been shown that the measured degradation and also the extracted time

exponent strongly depend on the time delay during measurement. Using fast

measurement methods to spot the full degradation during NBT stress reveals a

very low time exponent around  (see Section 6.3.6). The

reaction-diffusion model, in contrast, predicts a time exponent of

(see Section 6.3.6). The

reaction-diffusion model, in contrast, predicts a time exponent of  for

neutral hydrogen diffusion,

for

neutral hydrogen diffusion,

. By assuming molecular hydrogen being the

diffusing species a time exponent of

. By assuming molecular hydrogen being the

diffusing species a time exponent of  can be achieved. Here, an

additional reaction step at the interface generates molecular hydrogen before

diffusion,

can be achieved. Here, an

additional reaction step at the interface generates molecular hydrogen before

diffusion,

. Only by introducing higher order

chemical reactions at the interface the time exponent could be further reduced

to fit the model to state-of-the-art measurement results.

. Only by introducing higher order

chemical reactions at the interface the time exponent could be further reduced

to fit the model to state-of-the-art measurement results.

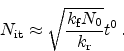

The fast recovery effect poses another inconsistency of the pure R-D model with

measurement data [99]. Even for very long stress times of more than

1000 seconds the immediate recovery of

in the first second after stress

is more than 60% using the fast measurement set-up.

in the first second after stress

is more than 60% using the fast measurement set-up.

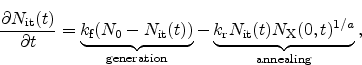

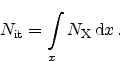

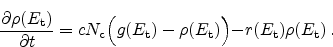

Figure 6.12:

Hydrogen profiles in the dielectric for 1000 second stress (left)

and after the recovery of 60 % of the degradation. It is difficult to

argue that the diffusion of more than half of the hydrogen which took 1000

seconds to diffuse into the dielectric can diffuse back to the interface in

one second [99].

|

|

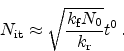

The R-D model assumes diffusion limited degradation and also diffusion limited

relaxation. When considering a stress time of 1000 seconds a certain amount of

hydrogen related species diffuses into the dielectric as shown in

Figure 6.12. The total amount of hydrogen in the dielectric must equal

the number of interface traps

(6.11).

(6.11).

is in turn

directly proportional to the shift of the threshold voltage

is in turn

directly proportional to the shift of the threshold voltage

. To argue

a 60% recovery during the first second in the framework of the R-D model,

60% of the hydrogen must diffuse back to the interface and anneal the

dangling silicon bonds within this second. This would result in a hydrogen

profile in the dielectric, as seen on the right hand side of

Figure 6.12, implying that the backward diffusion must be orders of

magnitude faster than the forward diffusion [99].

. To argue

a 60% recovery during the first second in the framework of the R-D model,

60% of the hydrogen must diffuse back to the interface and anneal the

dangling silicon bonds within this second. This would result in a hydrogen

profile in the dielectric, as seen on the right hand side of

Figure 6.12, implying that the backward diffusion must be orders of

magnitude faster than the forward diffusion [99].

6.4.3 Dispersive Transport

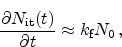

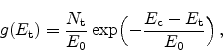

Figure 6.13:

Schematic illustration of dispersive transport. Hydrogen is

dissociated from the interface and transported into the

via a

diffusive mechanism. In the dielectric the mobile species sees traps of

different energies leading to dispersive transport. The energy diagram on

the right hand side shows a possible density-of-states (DOS) energy

distribution of the traps.

via a

diffusive mechanism. In the dielectric the mobile species sees traps of

different energies leading to dispersive transport. The energy diagram on

the right hand side shows a possible density-of-states (DOS) energy

distribution of the traps.

|

|

Instead of using the standard diffusion equation [103,105] to

describe hydrogen transport in the dielectric it has been

shown [88,106,107,108,109,110,111,112]

that correct modeling of transport in an amorphous materials must consider its

dispersive [113] nature.

Figure 6.14:

At small times the energy distribution of trapped carriers is

similar to the density-of-states (DOS) as the trapping probability for each

trap is the same. After time the peak of the energy distribution moves

towards deeper states. The reason is the higher de-trapping probability for

shallow traps.

|

|

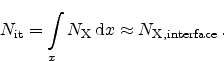

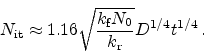

Dispersion arises when the mobile species experiences different barrier heights

at different positions in space. Figure 6.13 gives a schematic

illustration where the dielectric contains hydrogen traps of different energy.

The trapping probability at each trap is the same. But for de-trapping the

deeper traps pose a higher barrier than the shallow ones. This implies that at

the beginning of the trapping events the energy distribution of trapped

carriers is proportional to the density-of-states (DOS). But after some time,

as de-trapping preferably occurs for shallow traps, the peak of the energy

distribution moves to deeper traps as illustrated in

Figure 6.14. Thus, the equilibrium distribution is totally

different from the DOS.

In the modeling approach, the species

is separated into two distinct

contributions. The conducting,

is separated into two distinct

contributions. The conducting,

, and trapped,

, and trapped,

, particles. The

trapped particles are distributed in energy where the density at a trap

energy-level

, particles. The

trapped particles are distributed in energy where the density at a trap

energy-level

is given as

is given as

. The trapped particles do not

contribute to the transport. To introduce dispersive transport into the

reaction-diffusion model, (6.9) transforms to

. The trapped particles do not

contribute to the transport. To introduce dispersive transport into the

reaction-diffusion model, (6.9) transforms to

|

(6.23) |

At each trap energy-level a rate equation describes the dynamics between

trapping and de-trapping as

|

(6.24) |

Here,  is the capture rate,

is the capture rate,

the energy-dependent release rate,

and

the energy-dependent release rate,

and

is the trap DOS.

is the trap DOS.

When considering the trap distribution in exponential

form [113,92]

|

(6.25) |

and with introduction of the dispersion parameter

|

(6.26) |

can, for neutral species, be expressed with a power-law

as [114]:

can, for neutral species, be expressed with a power-law

as [114]:

|

(6.27) |

with

being the release rate coefficient. Here, only hydrogen in the

conductive state can contribute to the reverse rate.

being the release rate coefficient. Here, only hydrogen in the

conductive state can contribute to the reverse rate.

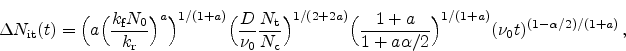

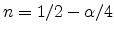

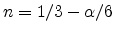

When assuming atomic hydrogen ( ) the slope calculates from

(6.27) as

) the slope calculates from

(6.27) as

while when assuming molecular hydrogen

(

while when assuming molecular hydrogen

( )

)

results in

results in

. In both cases the time exponent

. In both cases the time exponent

is increasing for an increasing dispersion parameter

is increasing for an increasing dispersion parameter  . So for an

increasing number of deep traps the degradation

increases [104,111].

. So for an

increasing number of deep traps the degradation

increases [104,111].

For complex trap distribution functions no analytic formulation can be found.

An example is a combination of shallow band-tail traps (the exponential

distribution) and deep Gaussian traps describing deep traps (right hand side of

Figure 6.13) [111]. For such a DOS only the

numerical solution is possible as obtained with the numerical device simulator

Minimos-NT.

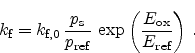

6.4.4 Coupling to the Semiconductor Device Equations

As NBTI is strongly dependent on the stress conditions, the available models

include at least the dependence on the electric field (the bias) and the

temperature. But also the hole concentration at the interface might be of

interest [85].

In the one-dimensional NBTI models the values of these quantities are accounted

for in the model parameters, as

and

and

in the reaction-diffusion model

for example. For each device, stress voltage, and temperature these parameters

are extracted (Section 7.1.2) and are assumed constant for these

stress conditions. But as degradation is continuing during stress, the

underlying parameters, especially the electric field across the interface,

change. So the electric field at the

in the reaction-diffusion model

for example. For each device, stress voltage, and temperature these parameters

are extracted (Section 7.1.2) and are assumed constant for these

stress conditions. But as degradation is continuing during stress, the

underlying parameters, especially the electric field across the interface,

change. So the electric field at the

interface is decreasing when the

NBTI induced degradation leads to positive charge build up at this interface.

Therefore, it might not be appropriate to consider the forward reaction rate

interface is decreasing when the

NBTI induced degradation leads to positive charge build up at this interface.

Therefore, it might not be appropriate to consider the forward reaction rate

as a constant.

as a constant.

Another point is the two-, or three-dimensional investigation of a device

structure. Here the electric field and the hole concentration, and therefore

also the magnitude of degradation, can change drastically across the channel of

the device when the stress conditions are not uniform

(Section 6.3.3). Thus, the model parameters are not uniformly

distributed at the

interface and a one-dimensional consideration of

the model might not be accurate enough [115].

interface and a one-dimensional consideration of

the model might not be accurate enough [115].

To solve these issues it is important to include the NBTI models into a

numerical device simulation. The distributed quantities, obtained from the

semiconductor device equations (Section 2.1) as the electric

field, hole and electron concentration can be directly used in the degradation

model. The resulting charge densities from the NBTI model can be included in

the device equation leading to a fully self-consistent coupling of those two

sets of equations.

The reaction-diffusion model might be linked to the semiconductor device

equations with the forward reaction rate as follows [85]

|

(6.28) |

Where

and

and

are the hole concentration and the electric field at the

interface,

are the hole concentration and the electric field at the

interface,

and

and

are reference values. By using solution

variables of the semiconductor equations the NBTI model can be applied to

arbitrary device geometries.

are reference values. By using solution

variables of the semiconductor equations the NBTI model can be applied to

arbitrary device geometries.

Next: 6.5 Tsetseris' Model

Up: 6. Negative Bias Temperature

Previous: 6.3 Physical Mechanisms of

R. Entner: Modeling and Simulation of Negative Bias Temperature Instability

![\includegraphics[width=12cm]{figures/nbti-schematic}](img521.png)

![\includegraphics[width=12cm]{figures/nbti-schematic}](img521.png)

![]() interface. Electrically inactive, passivated silicon dangling bonds

(Section 3.1), Si-H, are broken. Here an electrically

active interface state

interface. Electrically inactive, passivated silicon dangling bonds

(Section 3.1), Si-H, are broken. Here an electrically

active interface state

![]() and a mobile, hydrogen related species

and a mobile, hydrogen related species

![]() are

formed,

are

formed,

![]() dangling bond.

dangling bond.

![]() , are assumed as the diffusing species. The

process at the interface is modeled by a rate equation as

, are assumed as the diffusing species. The

process at the interface is modeled by a rate equation as

![]() . Thus, the transport mechanism of

the hydrogen species away from the interface characterizes the degradation

mechanism, controlling the device parameter shift. The original

reaction-diffusion model describes the transport as a purely diffusive

mechanism which is described by the diffusion equation

. Thus, the transport mechanism of

the hydrogen species away from the interface characterizes the degradation

mechanism, controlling the device parameter shift. The original

reaction-diffusion model describes the transport as a purely diffusive

mechanism which is described by the diffusion equation

![\includegraphics[width=12cm]{figures/rd-regimes}](img541.png)

![]() in the first second after stress

is more than 60% using the fast measurement set-up.

in the first second after stress

is more than 60% using the fast measurement set-up.

![\includegraphics[width=16cm]{figures/rd-vs-fast}](img563.png)

![]() (6.11).

(6.11).

![]() is in turn

directly proportional to the shift of the threshold voltage

is in turn

directly proportional to the shift of the threshold voltage

![]() . To argue

a 60% recovery during the first second in the framework of the R-D model,

60% of the hydrogen must diffuse back to the interface and anneal the

dangling silicon bonds within this second. This would result in a hydrogen

profile in the dielectric, as seen on the right hand side of

Figure 6.12, implying that the backward diffusion must be orders of

magnitude faster than the forward diffusion [99].

. To argue

a 60% recovery during the first second in the framework of the R-D model,

60% of the hydrogen must diffuse back to the interface and anneal the

dangling silicon bonds within this second. This would result in a hydrogen

profile in the dielectric, as seen on the right hand side of

Figure 6.12, implying that the backward diffusion must be orders of

magnitude faster than the forward diffusion [99].

![\includegraphics[width=16cm]{figures/nbti-dispersive-transport-gauss}](img564.png)

![\includegraphics[width=\figwidth]{figures/sg-trapping}](img565.png)

![]() is separated into two distinct

contributions. The conducting,

is separated into two distinct

contributions. The conducting,

![]() , and trapped,

, and trapped,

![]() , particles. The

trapped particles are distributed in energy where the density at a trap

energy-level

, particles. The

trapped particles are distributed in energy where the density at a trap

energy-level

![]() is given as

is given as

![]() . The trapped particles do not

contribute to the transport. To introduce dispersive transport into the

reaction-diffusion model, (6.9) transforms to

. The trapped particles do not

contribute to the transport. To introduce dispersive transport into the

reaction-diffusion model, (6.9) transforms to

![]() ) the slope calculates from

(6.27) as

) the slope calculates from

(6.27) as

![]() while when assuming molecular hydrogen

(

while when assuming molecular hydrogen

(![]() )

)

![]() results in

results in

![]() . In both cases the time exponent

. In both cases the time exponent

![]() is increasing for an increasing dispersion parameter

is increasing for an increasing dispersion parameter ![]() . So for an

increasing number of deep traps the degradation

increases [104,111].

. So for an

increasing number of deep traps the degradation

increases [104,111].

![]() and

and

![]() in the reaction-diffusion model

for example. For each device, stress voltage, and temperature these parameters

are extracted (Section 7.1.2) and are assumed constant for these

stress conditions. But as degradation is continuing during stress, the

underlying parameters, especially the electric field across the interface,

change. So the electric field at the

in the reaction-diffusion model

for example. For each device, stress voltage, and temperature these parameters

are extracted (Section 7.1.2) and are assumed constant for these

stress conditions. But as degradation is continuing during stress, the

underlying parameters, especially the electric field across the interface,

change. So the electric field at the

![]() interface is decreasing when the

NBTI induced degradation leads to positive charge build up at this interface.

Therefore, it might not be appropriate to consider the forward reaction rate

interface is decreasing when the

NBTI induced degradation leads to positive charge build up at this interface.

Therefore, it might not be appropriate to consider the forward reaction rate

![]() as a constant.

as a constant.

![]() interface and a one-dimensional consideration of

the model might not be accurate enough [115].

interface and a one-dimensional consideration of

the model might not be accurate enough [115].