![[ ′ ′ ]

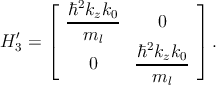

H ′ = H1 H 3 ,

H3′ H ′2](diss_htm247x.png)

A shear strain component in the [110] direction does not affect the primed valleys

along [100] and [010] directions. If a quantization along

![[ ′ ′ ]

H ′ = H1 H 3 ,

H3′ H ′2](diss_htm247x.png) | (4.48) |

where the individual components are represented as,

![[ 2 2 2 2 2 2 ]

H ′ = ℏ-kz-+ ℏ-(kx +-ky)+ (- 1)jℏ-kxky-+ ˜U(z) I,

j=1,2 2ml 2mt M](diss_htm248x.png) | (4.49) |

and

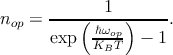

| (4.50) |

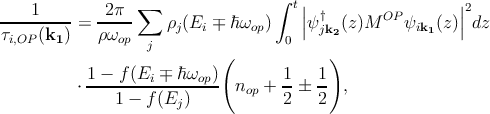

The intervalley f-processes are responsible for spin relaxation in bulk silicon which involves the primed subbands [53]. The spin relaxation rate is calculated by [69]

![2 ∑ ∫ 2π ∫ ∞

----1-----= -4π3d-0- dφ- -dqz--⋅|-|k2-|-|

τi,(fp)(k1 ) ℏρa2ωop j 0 2π -∞ (2π)2 ||∂E(k2)||

| | ∂k2

[ |∂E(k2)|f (E (k ))] ( )

||-∂k2-||------2--- 1- 1-

⋅ 1 - |∂E(k1)| nop + 2 ± 2

| ∂k1 |f (E (k1))

∑ | ∑ ∫ t |2

⋅ ||ϱoαp1(q) D α1α2 dzΨ *jk2-σ(z)exp (- iqzz)Ψik1σ(z)||

α1 0

(0)

⋅ θ (Ej (k2) - Ej ± ℏωop),](diss_htm250x.png) | (4.51) |

where

| (4.52) |

The +(-) sign refers to phonon emission (absorption). The relaxation rate for the transition between primed and unprimed subbands is given by [69]

| (4.53) |

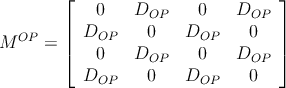

where

| (4.54) |

with  [53].

[53].

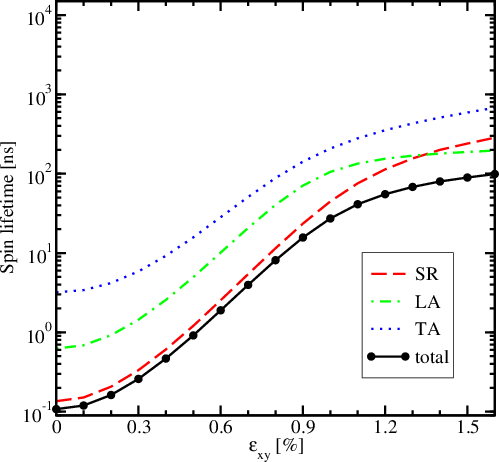

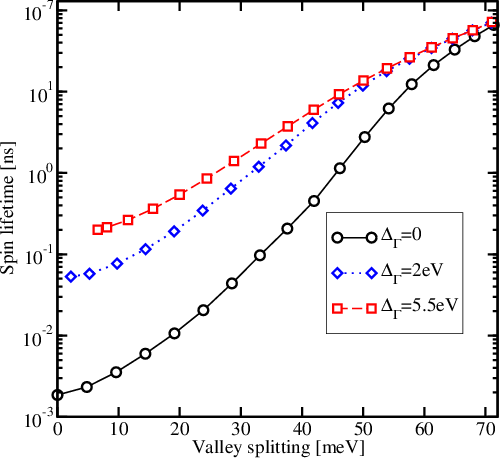

Figure 4.28 describes the total spin lifetime

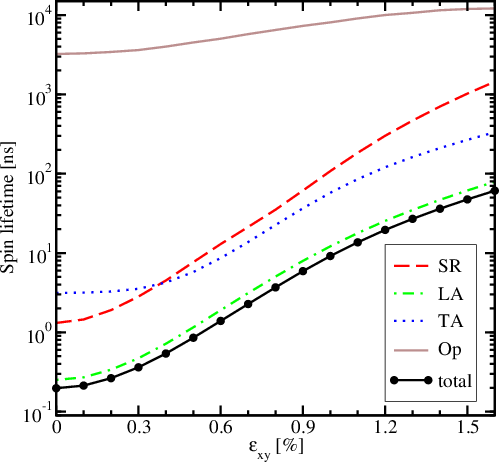

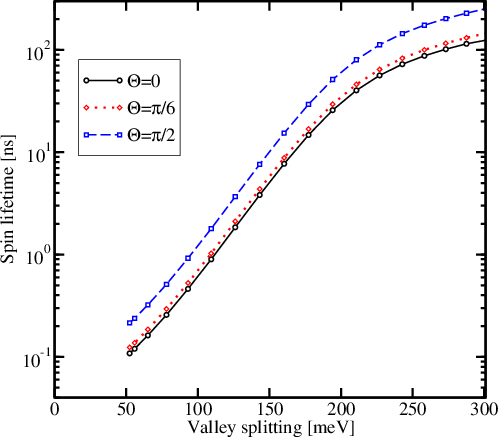

Figure 4.29 describes the variation of the total spin lifetime

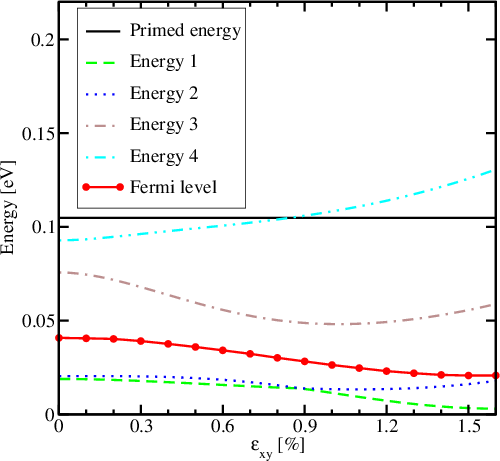

Thus, one can conclude in the following way.

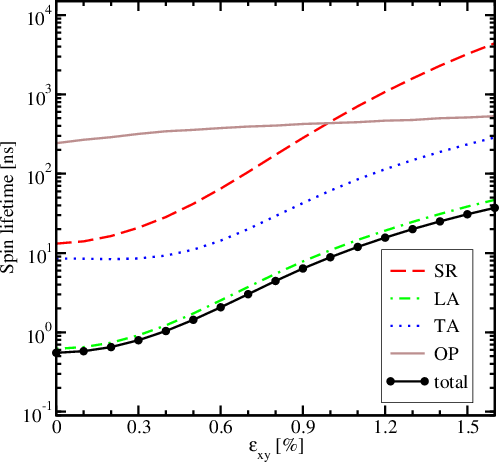

In Figure 4.32 the enhancement of the total spin lifetime

The spin relaxation time