-Characteristics

-Characteristics -Characteristics

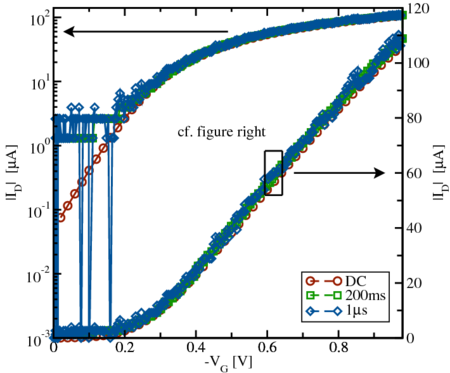

-CharacteristicsBased on the large discrepancy between the initial reference and the very first

measurement point visible in Fig. 5.1 and Fig. 5.2, different ways to

extract a reference of  are compared in Fig. 5.3 and Fig. 5.4. A

DC-characteristic and a slow

are compared in Fig. 5.3 and Fig. 5.4. A

DC-characteristic and a slow  -pulse sweep are both compared to the fast

-pulse sweep are both compared to the fast

-pulse sweep which is used for the fast pulsed

-pulse sweep which is used for the fast pulsed  -characteristics, cf.

Fig. 5.7.

-characteristics, cf.

Fig. 5.7.

-characteristics

obtained by two gate pulses with

-characteristics

obtained by two gate pulses with  and

and  . Due to the

limited resolution, especially the subthreshold region of the

. Due to the

limited resolution, especially the subthreshold region of the  is

affected by quantization noise.

is

affected by quantization noise.

While the DC-curve is averaged and hence very smooth, the slow and fast

pulses lack accuracy due to the missing averaging, as can be seen best in the

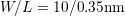

subthreshold regime, which is very noisy. As depicted in Fig. 5.4, setting the

threshold current criteria to  (linear drain current regime), yields

extracted values of

(linear drain current regime), yields

extracted values of  differing in around

differing in around  . This error is indicated as

. This error is indicated as

in Fig. 5.4.

in Fig. 5.4.

. They differ by

. They differ by  from each other, as marked by

from each other, as marked by

which is on the order of the obtained degradation for

which is on the order of the obtained degradation for  of PBTI

stress, cf. Fig. 5.6.

of PBTI

stress, cf. Fig. 5.6.

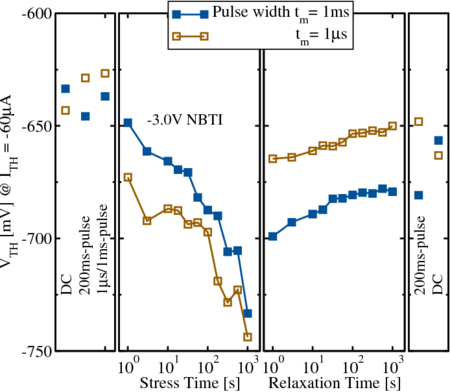

The impact of the various transfer characteristics used to get an initial

undegraded reference  to eventually measure

to eventually measure  during stress

is depicted for NBTI and PBTI stress in Fig. 5.5 and Fig. 5.6. Here

the fast pulsed

during stress

is depicted for NBTI and PBTI stress in Fig. 5.5 and Fig. 5.6. Here

the fast pulsed  -characterization using triangular

-characterization using triangular  - and

- and

-pulses with zero pulse high-time after Li et al. (cf. Chapter 2.2.1)

was applied to pMOS-devices with an

-pulses with zero pulse high-time after Li et al. (cf. Chapter 2.2.1)

was applied to pMOS-devices with an  provided by

IMEC1 .

provided by

IMEC1 .

-measurements (FPM) performed on

pMOS devices provided by IMEC after the method of Liu et al. Before

FPM is applied using different pulse widths for NBTI/PBTI stress,

-measurements (FPM) performed on

pMOS devices provided by IMEC after the method of Liu et al. Before

FPM is applied using different pulse widths for NBTI/PBTI stress,  is

determined in three different ways, cf. Fig. 5.3 and Fig. 5.4. Both stress and

recovery are interrupted

is

determined in three different ways, cf. Fig. 5.3 and Fig. 5.4. Both stress and

recovery are interrupted  times within three decades ranging from

times within three decades ranging from  to

to  for an FPM. Unfortunately, a high level of uncertainty is obtained

by extracting the threshold voltage manually. Applying NBTI stress yields

sound results because of the higher signal-to-noise ratio and the expected

negative shift of

for an FPM. Unfortunately, a high level of uncertainty is obtained

by extracting the threshold voltage manually. Applying NBTI stress yields

sound results because of the higher signal-to-noise ratio and the expected

negative shift of  .

.

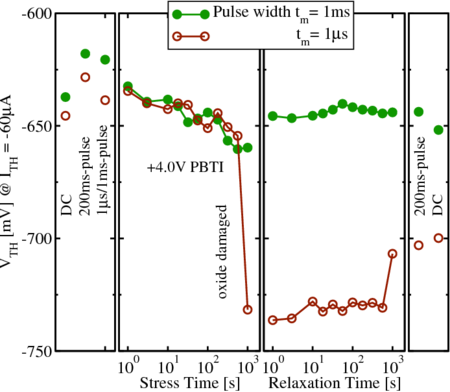

For PBTI stress Fig. 5.6 the determination of  delivers values which

are of the same order of magnitude as the following degradation itself, cf. first

and second subfigure. Depending on the chosen

delivers values which

are of the same order of magnitude as the following degradation itself, cf. first

and second subfigure. Depending on the chosen  -reference the

determined degradation hence varies by a factor of two. The same holds for the

relaxation mode (third subfigure) and its

-reference the

determined degradation hence varies by a factor of two. The same holds for the

relaxation mode (third subfigure) and its  -references taken at

-references taken at  ,

the DC-characteristics and slow

,

the DC-characteristics and slow  -pulse (forth subfigure). Even

more important is the fact that in contradiction to [24], the PBTI results

do not exhibit a positive

-pulse (forth subfigure). Even

more important is the fact that in contradiction to [24], the PBTI results

do not exhibit a positive  -shift at all, they solely show negative

-shift at all, they solely show negative

-shifts.

-shifts.

-measurements (FPM) performed on

pMOS devices provided by IMEC after the method of Liu et al. Before

FPM is applied using different pulse widths for NBTI/PBTI stress,

-measurements (FPM) performed on

pMOS devices provided by IMEC after the method of Liu et al. Before

FPM is applied using different pulse widths for NBTI/PBTI stress,  is

determined in three different ways, cf. Fig. 5.3 and Fig. 5.4. Both stress and

recovery are interrupted

is

determined in three different ways, cf. Fig. 5.3 and Fig. 5.4. Both stress and

recovery are interrupted  times within three decades ranging from

times within three decades ranging from  to

to  for an FPM. Unfortunately, a high level of uncertainty is obtained

by extracting the threshold voltage manually. When performing PBTI stress

again a negative shift of

for an FPM. Unfortunately, a high level of uncertainty is obtained

by extracting the threshold voltage manually. When performing PBTI stress

again a negative shift of  is found. This qualitatively supports the

results of Grasser et al. presented in [30]. The suddenly appearing offset of

is found. This qualitatively supports the

results of Grasser et al. presented in [30]. The suddenly appearing offset of

in-between the last two readout points during stress was assumed

to be due to heavy oxide damage.

in-between the last two readout points during stress was assumed

to be due to heavy oxide damage.

When the overall degradation becomes larger, as it is the case during NBTI

stress (Fig. 5.5), the error induced by the reference decreases as expected.

Unfortunately, the reason of the poor agreement of the differently extracted

initial and post  -values remains unclear. As these references do not

indicate any systematic error, but seem to vary randomly, a different

approach which is able to explain the deviating measurement results is

needed.

-values remains unclear. As these references do not

indicate any systematic error, but seem to vary randomly, a different

approach which is able to explain the deviating measurement results is

needed.