Next: 3.4 Process Simulation

Up: 3. The TCAD Concept

Previous: 3.2 Overview

Subsections

To start with the process simulation block some information has to be

prepared in a certain level of detail.

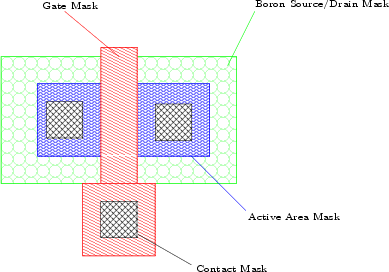

As in real semiconductor processing the layout of the device or integrated

circuit is a substantial input to the fabrication flow. It defines the lateral

composition of the circuitry and is the main variable input to the

semiconductor fabrication line 3.1. The

layout consists of the combination of a set of different mask levels. Each

mask level is defining a certain functional block during processing. As one

example, the gate level defines the sizes and orientation

of any CMOS gate inside the integrated circuit. As another example, the Boron

source/drain masks define the areas where the Boron for the PMOS source/drain

regions has to be implanted. The combination of these mask levels

characterizes the overall structure of certain devices. A simple example of

this concept is shown in Figure 3.3.

Figure 3.3:

Simple layout example of a PMOS transistor

|

It can be seen from this figure that the source/drain implant is drawn over

the gate layer too. However since in the fabrication process the gate layer is

masking the implantation, the real source/drain diffusion is only the logical

NOR operation of the two layers.

3.3.2 Mask Bias

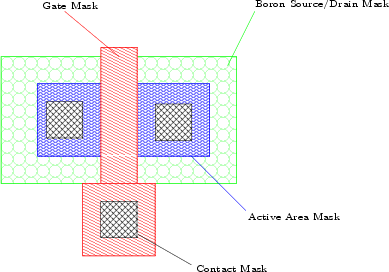

Mask bias is a post processing step during the fabrication of the chrome

reticle masks for lithography. Especial the patterning process is subject to

process related variations which have to be compensated with lithography. A

good example is the somewhat outdated 3.2 process module LOCOS (LoCal Oxidation of Silicon) [120]

isolation. Figure 3.4 shows the detailed process step chain

of this module.

Figure 3.4:

Typical LOCOS module sequence

|

Figure 3.4(a) shows the initial stack of the LOCOS sequence

consisting of the single crystalline silicon substrate, the so called pad

oxide consisting of Silicon Dioxide as a stress relief layer and Silicon

Nitride which acts as oxidation suppression mask for the oxidation of

silicon. Figure 3.4(b) shows the situation after spin-on of

the photo resist. On top of the structure the chrome reticle dimension for the

subsequent illumination step is shown. Furthermore, the initial dimension of

the mask data is shown. Since the drawn layout dimension should define the

final size of the area of the active region (the region not covered by field

oxide), the real chrome area has to be bigger (biased) in

size. A detailed outline of the algorithm for proper biasing of the

two-dimensional layout structures is given in Appendix C.

Figure 3.4(c) shows the situation after illumination,

development and hard bake of the photo resist. A couple of effects, like under

or overexposure, resist shrink during post exposure bake etc., may lead to

differences in the width of the photo resist structure and the initial reticle

dimension. These differences are the first contribution to the CD (critical

dimension) difference between the initial reticle size and the final size of

the structure of silicon. Figure 3.4(d) shows the CD loss

because of a small undercut of the Silicon Nitride during layer

etch. Additional CD loss may occur if the etching chemistry consumes small

parts of the capping photo resist layer. Figure 3.4(e) shows

the CD loss due to encroachment of the silicon nitride capping layer during

oxidation of the silicon. Finally Figure 3.4(f) gives the

situation after stripping of the capping nitride layer. If the initial

reticle mask bias compensates for the above mentioned effects during the

steps (c) through (e) in Figure 3.4, the final CD matches exactly the initially drawn layout

dimension. Since the processing effects depend critically on the details of

the manufacturing process, this biasing is called fabrication specific.

Another important convolution of the initial mask input to process simulation

are the mask proximity effects due to the diffraction effects during

photo resist exposure. The underlying physics was described in

Section 2.4 in detail. A simulation taking into

account these effects is outlined in

Section 6.3. An example of the magnitude of these

effects for a typical 350nm node mask illuminated with i-line lithography is

shown in Figure 3.5.

Figure 3.5:

Initial layout of a part of an EEPROM cell (a),

contour plots of intensity distribution during the illumination

of photo resist at different levels (b)-(e) and resulting resist

contours after development (f).

|

![\includegraphics[width=0.8\textwidth]{figures/eearray_layout.ps}](img135.png)

(a)

|

![\includegraphics[width=0.8\textwidth]{figures/eearray_FG.ps}](img136.png)

(b)

|

![\includegraphics[width=0.8\textwidth]{figures/eearray_P1.ps}](img137.png)

(c)

|

![\includegraphics[width=0.8\textwidth]{figures/eearray_CO.ps}](img138.png)

(d)

|

![\includegraphics[width=0.8\textwidth]{figures/eearray_M1.ps}](img139.png)

(e)

|

![\includegraphics[width=0.8\textwidth]{figures/eearray_contours.ps}](img140.png)

(f)

|

|

Figure 3.5(a) shows the initial layer data for some

levels during fabrication of a EEPROM cell [11],[122] (Floating Gate, Gate Poly, Contact

and Metal 1). Figure 3.5(b) through

Figure 3.5(e) show the intensity distribution during resist

illumination. Figure 3.5(f) shows the extracted iso

contours (at same level of intensity) of the 4 layers demonstrating the above

mentioned proximity effects during lithography.

By applying these simulations the resulting proximity corrected contours can be

used as an input to the process simulation in the usual CIF or GDSII

formats. Therefore, the layout may be preprocessed once to reflect the real

mask shapes more closely. To simplify the resulting contour polygons a

polygon point reduction algorithm, the minmax-method [123]

has been used. An example of the results of such a preprocessing of

the mask layout can be found in Section 6.3

In Chapter 2 it has been outlined, that

the clean room production flow is a fairly linear flow but of high

complexity with respect to the production path in the

fabrication. Since this flow has to be documented extremely well to

prevent misprocessing, a so called MES (Manufacturing Execution

System) is used to control the wafers during their full processing

flow. Controlling means tracking of the current position in the

process flow and defining the correct machine recipes at the correct

positions of the flow. This process flow (to name it short) is a list

of single process steps which determine WHEN and HOW the wafer surface

has to be modified by implantation, etching, deposition, and masking to

form an integrated circuit at the end.

There are two classes of process simulation steps. On one side the

``physical'' process steps ion implantation, oxidation and diffusion

where the machine parameters (recipes) are inputs to the process

simulation also. In contrast to this class there are the ``chemical''

process steps etching and deposition, where currently there are no

stable, reliable and sufficiently fast models available to model these

steps with their process recipes (pressure, temperature over time)

rigorously. These steps are modeled via simple geometric ``emulation''

of the outcoming topology change after the run recipe. Therefore, the

calibration of these steps is very important. Lithography is in part

``physical'' (illumination) and in part ``chemical'' (PAC reaction and

development), and normally it its treated as deposition and

etching in terms of geometrical modeling. In terms of illumination it

has been shown in the previous section, how to care about these effects.

To finally get the deserved simulation results by process

simulation with appropriate accuracy, it is mandatory to

mimic the real processing with a high level of detail provided

by the physical models of the process simulator. A good example of

such an approach is the implementation of a diffusion and oxidation

recipe in a process simulator as shown in

Section 6.1. In this example every

single change in temperature (temperature ramps) or pressure (pressure

ramps) or gas ambient change (oxidizing ambient instead of inert

ambient) above a certain temperature where the diffusion models of

the process simulator are calibrated and valid, was defined as a

single command for the process simulator. The final simulation program

consists of a sequence of different process conditions of a certain

time. In the past this concept was not employed because of the big

penalty in simulation time. In contrast only the ``main thermal step''

was defined as a process simulation command. The new concept has the

big advantage of being not prone to the judgement of the TCAD engineer,

which of the numerous single diffusion steps (between 8 and 30) is now

the most dominant and important one.

In Table 3.1 a comparison of the

current levels of details in the process flow information according to

the current status of the physical models of the available process

simulators is given. The process steps deposition, etching, and

lithography were left out on purpose since these steps are normally

not modeled via equipment level simulation (input parameters to the

simulation are the process recipes) but via geometrical approximation

as outlined above.

Table 3.1:

Examples for

current level of details in the description of semiconductor process steps

| Step |

Low Detail |

Medium Detail |

High Detail |

|---|

| diffusion |

temp. |

pressure |

temp. |

pressure |

temp. |

pressure |

| & |

time |

flow rates |

time |

flow rates |

time |

flow rates |

| oxidation |

|

|

temp. ramps |

|

temp. ramps |

gas ramps |

| |

of main diff. step |

of all diffusion steps |

of all diffusion steps |

| ion |

dose |

energy |

dose |

energy |

dose |

energy |

| implantation |

tilt |

|

tilt |

revolving |

tilt |

revolving |

| |

|

|

|

|

beam div. |

ioniz. level |

|

Footnotes

- ... line 3.1

- except the process technology itself which

could be varied based on the needs of the product, however in a standard

semiconductor fabrication the number of different process technologies is far

less than the number of integrated circuits on ONE technology platform

- ... outdated 3.2

- the module is the standard

approach for the transistor isolation for technology nodes

250nm

250nm

Next: 3.4 Process Simulation

Up: 3. The TCAD Concept

Previous: 3.2 Overview

R. Minixhofer: Integrating Technology Simulation

into the Semiconductor Manufacturing Environment