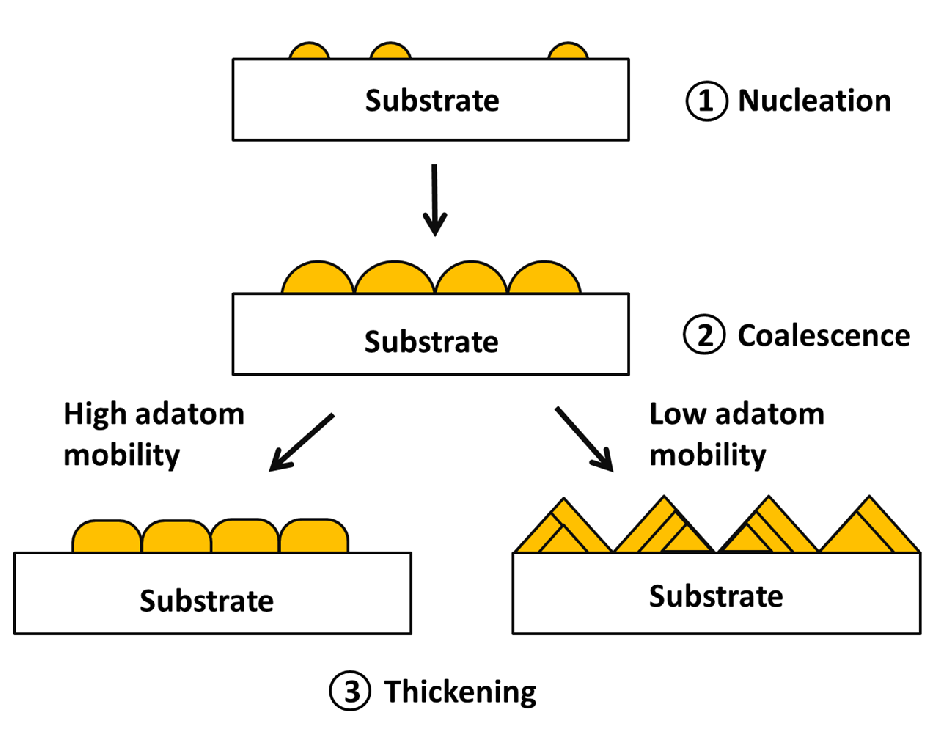

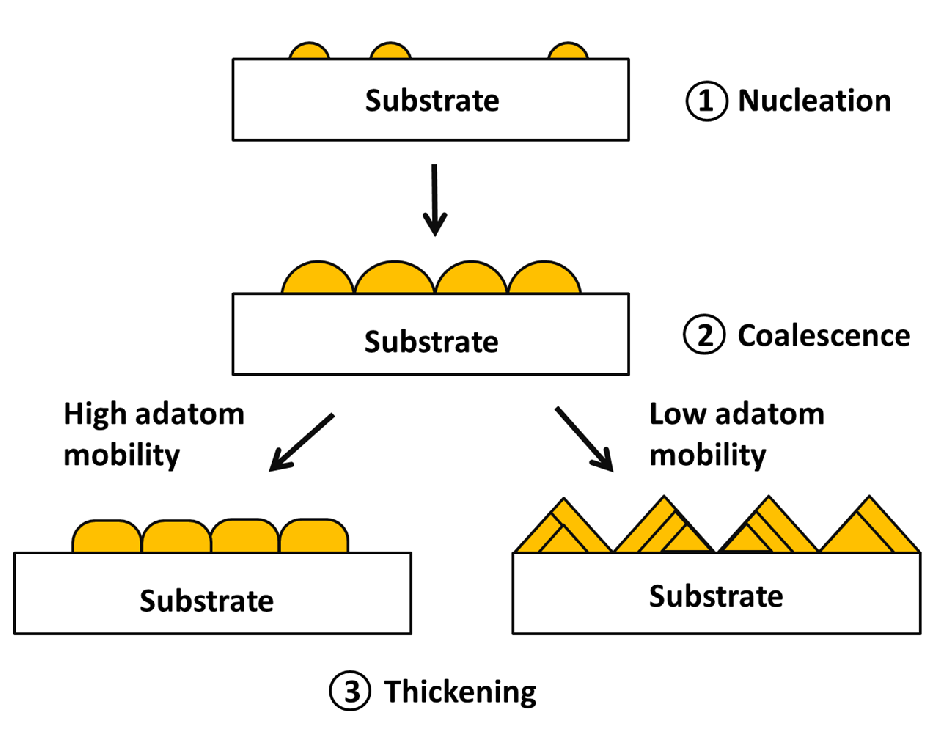

| Figure 6.3.: | Metal film growth process. The final film structure depends on the adatom mobility of the depositing metal. |

The focus of this section will remain concentrated on the metal layers used along the TSV sidewall, where high stress can lead to failure of the entire via, especially in the presence of Bosch scallops, as seen in Chapter 5. During metal deposition, stress arises as a result of physical mechanisms which take place during film growth. Those stresses are strongly related to the fabrication process and are known as intrinsic stress or residual stress [98][99][100][101][102][103].

The residual stress can arise from various sources, as suggested in Table 5.1. A misfit between lattice parameters, microstructural modifications (e.g. grain growth, coalescence) and deposition method are examples of the most common residual stress sources [101]. In Volmer-Weber mode, the residual stress builds up since the initial stages of nucleation. The lack of affinity between metal and substrate atoms leads to the retraction of the atoms in the droplets. Therefore, the island becomes compressed and stress is generated from it. The compressive stress increases continually with island growth until coalescence, where the merging process (also known as zipping) joins them and a tensile force arises. As more droplets come together the tensile stress increases very fast, suppressing the compressive component and leaving the film in a high tensile state. At this point the material can have two different behaviors, depending on the adatom mobility. If the material has high adatom mobility (e.g. Cu, Al, Ag), the new adatoms will move towards the grain boundaries, increasing the grain sizes. This grain growth leads to a compressive pressure in the film and counterbalances the coalescence tensile stress. For materials with low mobility, the new adatoms do not move so easily, which diminishes the compressive force triggered by the adatoms movement. A summary of the microstructure evolution is depicted in Fig. 6.3 and the stress evolution along the growth is shown in Fig. 6.4.

| Figure 6.3.: | Metal film growth process. The final film structure depends on the adatom mobility of the depositing metal. |