4.3.1 Band Gap Energy

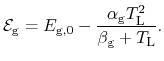

The Varshni formula [313] well describes the temperature

dependence of the band gap in nitrides with:

The values for

(energy band gap at 0 K),

(energy band gap at 0 K),

,

and

,

and

(empirical constants) for GaN, AlN and InN are

summarized in Table 4.6. The parameters for GaN are an

average of various reported results as summarized in

[209], those for AlN are based on the experimental work of

Guo et al. [314]. For InN the parameters are taken from

[315], where three different techniques were used to study the

band gap energy and its properties. The results are in agreement with the

recently reevaluated band gap energy of InN as discussed in

Section 3.3.

(empirical constants) for GaN, AlN and InN are

summarized in Table 4.6. The parameters for GaN are an

average of various reported results as summarized in

[209], those for AlN are based on the experimental work of

Guo et al. [314]. For InN the parameters are taken from

[315], where three different techniques were used to study the

band gap energy and its properties. The results are in agreement with the

recently reevaluated band gap energy of InN as discussed in

Section 3.3.

Table 4.6:

Summary of band structure model parameters.

| Material |

E

[eV] [eV] |

[eV/K] [eV/K] |

[K]

[K] |

| GaN |

3.4 |

9.09 10 10 |

800 |

| AlN |

6.2 |

18.0 10 10 |

1462 |

| InN |

0.69 |

4.14 10 10 |

454 |

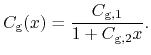

The band gap of semiconductor alloys is interpolated by Vegard's law

[316]:

with the bowing parameter

. The reported values for

Al

. The reported values for

Al Ga

Ga N of the latter show a large variation ranging from

N of the latter show a large variation ranging from

0.8 eV [317] to

0.8 eV [317] to  1.33 eV

[318]. However, several experiments [319,320] show a

linear variation (

1.33 eV

[318]. However, several experiments [319,320] show a

linear variation (

0 eV) which is adopted here.

0 eV) which is adopted here.

For InGaN a bowing parameter

=1.4 eV in agreement with the

work of Walukievicz et al. [315] is well established. It

corresponds to the theoretical value given by Caetano et al.

[321] (

=1.4 eV in agreement with the

work of Walukievicz et al. [315] is well established. It

corresponds to the theoretical value given by Caetano et al.

[321] (

=1.44 eV). Other theoretical studies show

that a single bowing parameter cannot be used for the whole alloy

band gap [322,323]. While the dependence of the bowing

parameter on the composition in the aforementioned works is weak, it

still remains to be experimentally verified. Until such studies are

available,

=1.44 eV). Other theoretical studies show

that a single bowing parameter cannot be used for the whole alloy

band gap [322,323]. While the dependence of the bowing

parameter on the composition in the aforementioned works is weak, it

still remains to be experimentally verified. Until such studies are

available,

=1.4 eV and

=1.4 eV and

=2.1 eV for unstrained and

strained samples, respectively, are adopted [324]

=2.1 eV for unstrained and

strained samples, respectively, are adopted [324]

Several works suggest a bowing parameter with a value ranging from

3.0 eV and 6.1 eV [315,325] for InAlN. Those large

disagreements can be attributed to low crystalline quality and high

doping levels. Recent calculations and experimental studies showed,

however, that the bowing parameter for InAlN is strongly dependent on

the material composition [326,327]. In order to

account for this dependence the following expression is proposed

in [327]:

In the same work, the authors propose a value of 15.3 eV and 4.81 eV

for

and

and

, respectively. As shown

in Fig. 4.8 this model achieves a very good

agreement with the experimental data from various other

studies [328,329,330]. The dependence of the

band gap on composition should be attributed to charge transfer

effects, related to the large electronegativity differences between

III-V atoms [322]. However, as pointed out

in [331] Vegard's law is applicable for lattice

matched composition (

, respectively. As shown

in Fig. 4.8 this model achieves a very good

agreement with the experimental data from various other

studies [328,329,330]. The dependence of the

band gap on composition should be attributed to charge transfer

effects, related to the large electronegativity differences between

III-V atoms [322]. However, as pointed out

in [331] Vegard's law is applicable for lattice

matched composition ( 17% as reported in [332]),

which is mostly interesting for HEMT applications. For reference the

result obtained using a constant

17% as reported in [332]),

which is mostly interesting for HEMT applications. For reference the

result obtained using a constant

=3 eV is depicted, too.

=3 eV is depicted, too.

S. Vitanov: Simulation of High Electron Mobility Transistors

![]() =1.4 eV in agreement with the

work of Walukievicz et al. [315] is well established. It

corresponds to the theoretical value given by Caetano et al.

[321] (

=1.4 eV in agreement with the

work of Walukievicz et al. [315] is well established. It

corresponds to the theoretical value given by Caetano et al.

[321] (

![]() =1.44 eV). Other theoretical studies show

that a single bowing parameter cannot be used for the whole alloy

band gap [322,323]. While the dependence of the bowing

parameter on the composition in the aforementioned works is weak, it

still remains to be experimentally verified. Until such studies are

available,

=1.44 eV). Other theoretical studies show

that a single bowing parameter cannot be used for the whole alloy

band gap [322,323]. While the dependence of the bowing

parameter on the composition in the aforementioned works is weak, it

still remains to be experimentally verified. Until such studies are

available,

![]() =1.4 eV and

=1.4 eV and

![]() =2.1 eV for unstrained and

strained samples, respectively, are adopted [324]

=2.1 eV for unstrained and

strained samples, respectively, are adopted [324]