![\includegraphics[width=0.5\linewidth]{shadowing}](img112.png)

|

Fundamental physical mechanisms in deposition and etching processes generate both desired and undesired topographic features. In this chapter we provide a basis for understanding and modeling these effects on topography. A common framework for modeling etching and deposition is given, including the terminology used for describing the various physical phenomena and effects.

The starting point for both is the nature of flux which arrives from a source above the wafer. The second commonality is how the self-shadowing of an existing profile affects the visibility of the source and how the re-emission from the profile or radiosity affects other points of the profile. The third common aspect is that mechanical and chemical reactions at the surface determine the local advancement rate and are one of the most challenging aspects of deposition and etching. The final common characteristic of deposition and etching is the time-advance of the surface profile. In this chapter we focus on this final common aspect.

![\includegraphics[width=0.5\linewidth]{protective2}](img113.png)

|

The local fluxes and etch or deposition reactions provide sufficient information on how the surface is to be deformed for a short time step. The time evolution of the profile requires many time increments which allow the change of the profile shape to influence its future shape through shadowing, etc. As the surface evolves there may be major topological changes. For example, outgrows of the material from sides of a trench might collide and close off a void, or etch fronts from two trenches might move laterally, collide and form a tunnel or an air bridge.

To ease the presentation a simpler two-dimensional case will

be used. In two dimensions the profile is sometimes said to be made of

line segments and intersections points which may also be called

nodes. Figure 3.3 shows the simulation result of an

isotropic deposition of a material into a rectangular structure. It

can be seen easily that the boundary is expanded radially outward for a time step

![]() . The top right convex outward corner point causes a fan

(cf. Figure 3.3) of facets to be generated which creates a rounded section in the profile at

time

. The top right convex outward corner point causes a fan

(cf. Figure 3.3) of facets to be generated which creates a rounded section in the profile at

time ![]() . At the concave outward corner the planar fronts from the

horizontal and vertical facets intersect in a line which is

the location of a new corner point. These collisions where

overlapping fronts occur and some information about the initial

profile is lost are said to be shocks (cf. Figure 3.3). Note that shocks and fans

play a very important role in determining the changes of topography

during processing. For isotropic etching the profile moves from the

surface into the material as shown in

Figure 3.4. As expected the convex outward corner

now produces a shock and the concave corner point produces a fan.

. At the concave outward corner the planar fronts from the

horizontal and vertical facets intersect in a line which is

the location of a new corner point. These collisions where

overlapping fronts occur and some information about the initial

profile is lost are said to be shocks (cf. Figure 3.3). Note that shocks and fans

play a very important role in determining the changes of topography

during processing. For isotropic etching the profile moves from the

surface into the material as shown in

Figure 3.4. As expected the convex outward corner

now produces a shock and the concave corner point produces a fan.

|

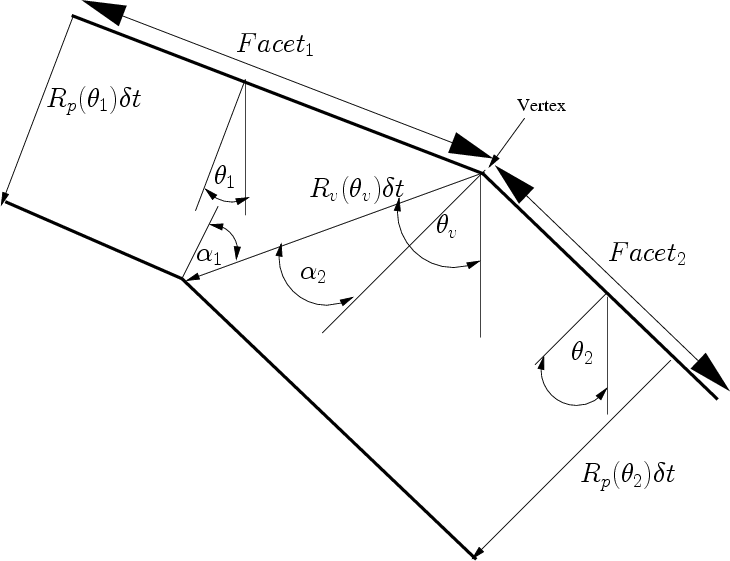

To understand faceting of the initial profile the advancement

of two neighboring facets as shown in

Figure 3.5 is considered. The direction and rate of

advance of a vertex where two facets intersect is of key interest. The two

facets have downward

normals which form angles

![]() and

and

![]() with respect

to the vertical downward direction. They advance a distance which is

the product of the planar etch rate for their orientation

with respect

to the vertical downward direction. They advance a distance which is

the product of the planar etch rate for their orientation

![]() and time step

and time step ![]() as

as

![]() and

and

![]() , respectively. The vertex moves at an angle

, respectively. The vertex moves at an angle

![]() and a rate

and a rate

![]() and therefore a distance

and therefore a distance

![]() . The angles of the path of this vertex with respect to the normal of the

two facets are

. The angles of the path of this vertex with respect to the normal of the

two facets are

![]() and

and

![]() which are

which are

![]() and

and

![]() ,

respectively. Projecting the distance of movement of this

vertex onto the distances advanced by the facets gives the two following

equations:

,

respectively. Projecting the distance of movement of this

vertex onto the distances advanced by the facets gives the two following

equations:

Taking the ratio between (3.1) and (3.2) and

eliminating

![]() gives

gives

Once

![]() is known the associated rate

is known the associated rate

![]() can

be found from (3.1) and (3.2) and is of course higher

than

can

be found from (3.1) and (3.2) and is of course higher

than

![]() and

and

![]() .

.

(3.3) makes a number of interesting predictions about

the physical nature of the motion of the vertex. Assuming

that

![]() and

and ![]() is not a

function of the facet angle

is not a

function of the facet angle ![]() , then the right hand side of

(3.3) is unity, forcing

, then the right hand side of

(3.3) is unity, forcing

![]() or

or

![]() which means that the

intersection vertex moves along the bisecting angle.

which means that the

intersection vertex moves along the bisecting angle.

Another important case is that ![]() increases with the angle

increases with the angle

![]() . This makes the right hand side of (3.3)

. This makes the right hand side of (3.3)![]() which leads to

which leads to

![]() or

or

![]() . This means that the

faster moving facet will encroach into the region of the slower moving

facet and likely expands in size.

. This means that the

faster moving facet will encroach into the region of the slower moving

facet and likely expands in size.

To further explore how the movement of a facet depends on the shape of

the rate function, the direction of travel of a facet at angle ![]() with rate function

with rate function

![]() is now derived in a limiting

case. Assuming that the angle between a facet pair is small enough,

their intersection vertex will propagate in the direction of motion of

the facet. This limiting case can be determined from

(3.3) by taking the special case of

is now derived in a limiting

case. Assuming that the angle between a facet pair is small enough,

their intersection vertex will propagate in the direction of motion of

the facet. This limiting case can be determined from

(3.3) by taking the special case of

![]() and

and

![]() and letting

and letting

![]() go to

zero. Substituting

go to

zero. Substituting

![]() and

and

![]() in

(3.3) and expanding

in

(3.3) and expanding ![]() in a Taylor series gives

in a Taylor series gives

Letting

![]() go to zero in (3.4) gives

go to zero in (3.4) gives

(3.5) indicates that a facet at angle ![]() moves

laterally with a rate component proportional to the slope of the rate

function

moves

laterally with a rate component proportional to the slope of the rate

function

![]() as well as

normal to the surface at the usual rate

as well as

normal to the surface at the usual rate

![]() .

.

Regarding the evolution of facets each facet has a plane associated with it. The plane moves with a given normal speed which may be different for different facets. The boundaries of the facets are determined by the intersection of the planes. The two-dimensional evolution near a corner is shown in Figure 3.6. If we use a level-set method where the normal speed is a simple interpolation between the two normal speeds, then the corners would be rounded, as shown in Figure 3.7 (in particular, an arc of a circle would arise, if the two speeds are the same). In order to keep flat facets and sharp corners, the following precautions must be made. The evolution of a smooth curve only depends on the normal speed, the addition of a tangential component only has the effect of changing the parameterization of the curve. With a velocity that has a proper tangential component to the facet and is directed towards a corner, the facets will evolve maintaining sharp

|

In order to minimize the corner rounding during the movement of a

boundary the approach introduced by Russo and Smereka [71] can

be used where the speed of each facet must be specified.

Consider an interface consisting of ![]() facets, with normals

facets, with normals

![]() and absolute value of normal

speeds

and absolute value of normal

speeds

![]() for

for ![]() . Let

. Let

![]() be the normal

at a given point of the interface.

be the normal

at a given point of the interface.

In order to compute the proper velocity of the surface at a given

point, first the facet is selected which is closest in direction to

![]() , i.e., for which

, i.e., for which

![]() is a maximum,

is a maximum,

| (3.6) |

Next the following velocity is defined

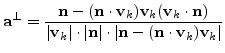

Some simple geometric considerations as shown in Figure 3.8 and the following equations help us to find the tangential speed that must be added to keep a sharp corner.

| (3.10) |

| (3.11) |

The quantity ![]() can then be chosen equal to

can then be chosen equal to ![]() , where

, where

| (3.12) |

For a faceted interface

![]() , because

, because

![]() and the facet

will evolve with the standard normal speed. On the other hand, if we

evolve the whole interface with the velocity

and the facet

will evolve with the standard normal speed. On the other hand, if we

evolve the whole interface with the velocity

![]() , then the

corners get rounded as shown in Figure 3.7. When the corners

become slightly rounded, then

, then the

corners get rounded as shown in Figure 3.7. When the corners

become slightly rounded, then

![]() becomes directed towards the corners

and the surface will move with a velocity that will try to keep the

corners sharp.

becomes directed towards the corners

and the surface will move with a velocity that will try to keep the

corners sharp.

Choosing a small value for

![]() , the vector

, the vector

![]() is basically a

unit vector whenever

is basically a

unit vector whenever

![]() is not aligned with the facets. Neglecting

is not aligned with the facets. Neglecting

![]() , the normal speed

, the normal speed

![]() can be calculated from

(3.7) with the following equation

can be calculated from

(3.7) with the following equation

|

(3.14) |

Substituting (3.15) in (3.13) gives the normal speed of our model for the level set function

| (3.16) |

In Chapter 7 we will present the application of this method to get the trenches with a minimal corner rounding during the simulation of an etching process.