6.5.2 Coalescence Simulation

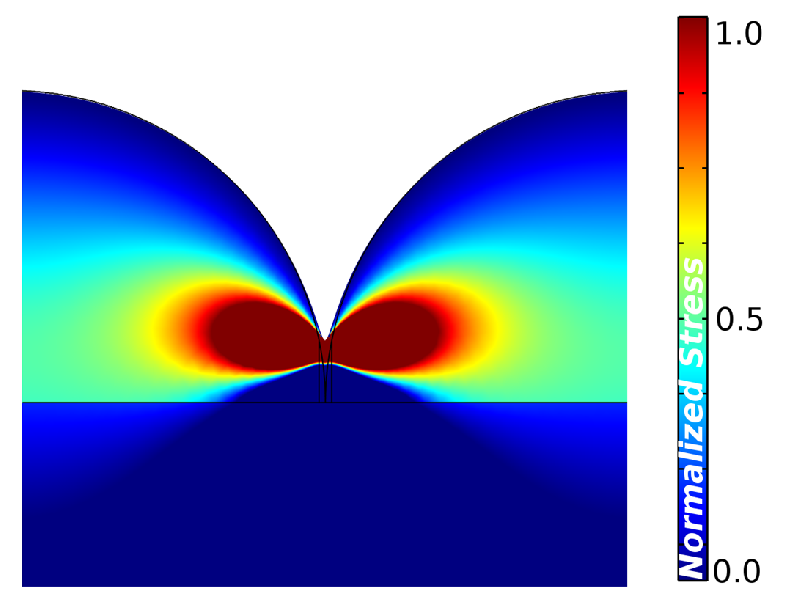

After a VW growth simulation, a sample is taken from the droplet size distribution and a

FEM simulation is performed in order to compute the stress. The setup follows Seel’s

scheme, but  is not computed from the FEM simulations; instead the numerical

minimization of (6.8) regarding

is not computed from the FEM simulations; instead the numerical

minimization of (6.8) regarding  is used. This approach is faster, because it avoids extra

FEM simulations in the search for

is used. This approach is faster, because it avoids extra

FEM simulations in the search for  . A FEM simulation example of a grain encounter is

shown in Fig. 6.11.

. A FEM simulation example of a grain encounter is

shown in Fig. 6.11.

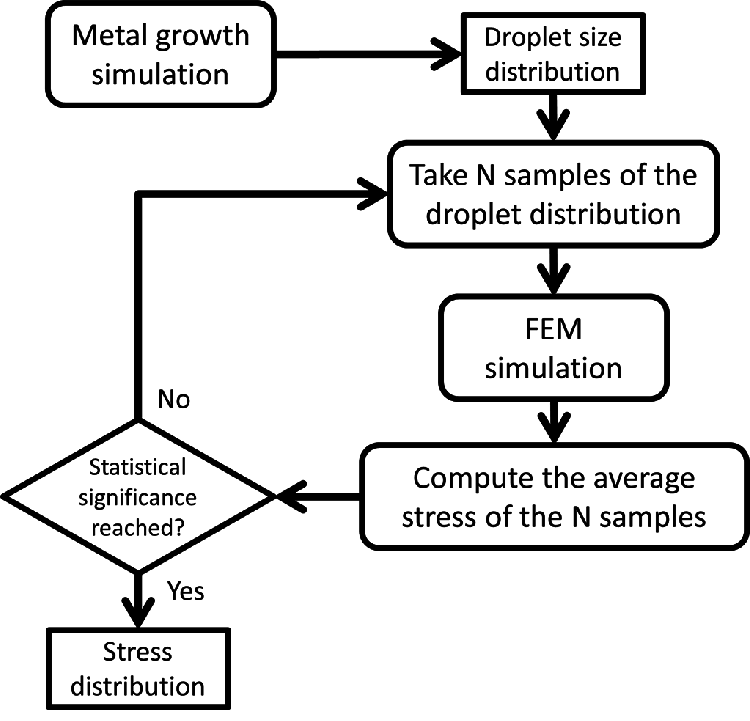

The calculated stresses are then averaged and the entire process is repeated for a new

sample from the droplets’ size distribution, until it reaches statistical significance (usually in

the order of several thousand simulations). Finally, an estimate for the average stress in the

film can be calculated together with the confidence interval. The method is summarized in

Fig. 6.12.

is not computed from the FEM simulations; instead the numerical

minimization of (6.8) regarding

is not computed from the FEM simulations; instead the numerical

minimization of (6.8) regarding  is used. This approach is faster, because it avoids extra

FEM simulations in the search for

is used. This approach is faster, because it avoids extra

FEM simulations in the search for  . A FEM simulation example of a grain encounter is

shown in Fig. 6.11.

. A FEM simulation example of a grain encounter is

shown in Fig. 6.11.

.

.