-Based Memristors

-Based Memristors

-Based Memristors

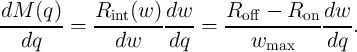

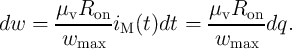

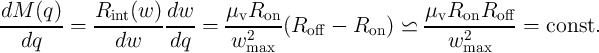

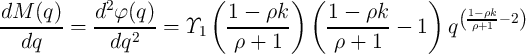

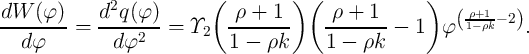

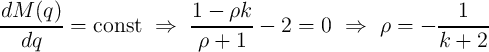

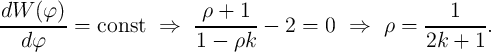

-Based MemristorsAccording to Eq. 3.7, the term  for the TiO

for the TiO -based memristor is obtained as

-based memristor is obtained as

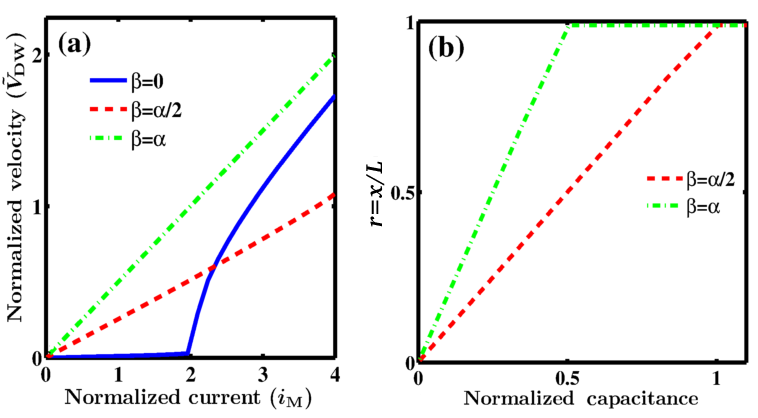

| (6.11) |

From Eq. 3.8, we then obtain

| (6.12) |

Therefore, we get

| (6.13) |

Thus, according to Eq. 6.4 and Eq. 6.5, this device can be used for charge-based memristive sensing.

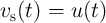

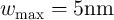

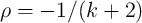

Let us consider a memristor-capacitor (MC) circuit shown in the inset of Fig. 6.5d. Fig. 6.5a

shows the  characteristics of the memristor, when the MC circuit is excited by a step

voltage source

characteristics of the memristor, when the MC circuit is excited by a step

voltage source  where

where  =0 for

=0 for  and 1 for

and 1 for  . The memristor exhibits

different behavior for different capacitances. As it is expected, the smaller the capacitance the

smaller the charging time (Fig. 6.5b) as well as the smaller the charge modulation. Thus, the

memristance exhibits smaller modulation for smaller capacitance (Fig. 6.5c). This is the key idea to

measure the capacitance by using Eq. 6.4 based on the modulations of the voltage across the

capacitor and the memristance. According to Eq. 6.4, if the measurement is performed after the

capacitor is fully charged (

. The memristor exhibits

different behavior for different capacitances. As it is expected, the smaller the capacitance the

smaller the charging time (Fig. 6.5b) as well as the smaller the charge modulation. Thus, the

memristance exhibits smaller modulation for smaller capacitance (Fig. 6.5c). This is the key idea to

measure the capacitance by using Eq. 6.4 based on the modulations of the voltage across the

capacitor and the memristance. According to Eq. 6.4, if the measurement is performed after the

capacitor is fully charged ( ), only the memristance modulation has to be measured.

However, depending on the readout resolution, the measurement can be performed in a time interval

(much) shorter than the full charge time (Fig. 6.5d). In Fig. 6.5, the TiO

), only the memristance modulation has to be measured.

However, depending on the readout resolution, the measurement can be performed in a time interval

(much) shorter than the full charge time (Fig. 6.5d). In Fig. 6.5, the TiO -based memristor

device characteristics are assumed as

-based memristor

device characteristics are assumed as  ,

,  ,

,  , and

, and

[69].

[69].

| Figure 6.5.: | (a) TiO memristor memristor  curves. (b) The voltage of the capacitor and (c) the memristance as a function

of time. (d) Obtained capacitances by using Eq. 6.4. curves. (b) The voltage of the capacitor and (c) the memristance as a function

of time. (d) Obtained capacitances by using Eq. 6.4. |

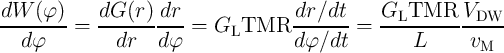

Fig. 6.6 shows two magnetoresistive spintronic memristors with current-induced domain wall motion in a

giant magnetoresistance spin-valve (Fig. 6.6a) and a tunneling device (Fig. 6.6b). The electrical resistance

(conductance) of these devices  (

( ) is a function of the DW position (

) is a function of the DW position ( ) in the magnetic

free layer [96, 94, 137]. A complete antiparallel alignment results in a high-resistance state (HRS;

) in the magnetic

free layer [96, 94, 137]. A complete antiparallel alignment results in a high-resistance state (HRS;

) of the device, while a fully parallel alignment places it in a low-resistance state (LRS;

) of the device, while a fully parallel alignment places it in a low-resistance state (LRS;

).

).

For the domain wall giant magnetoresistance (DW-GMR) the memristor  is given by [96]

is given by [96]

R(r) =  | = RP(r) + RAP(r) = rRL + (1 - r)RH | ||

| = RH - r(RH - RL) = (1 - rGMR)RL, | (6.14) |

where  is the domain wall position,

is the domain wall position,  represent the relative DW position, and

represent the relative DW position, and  denotes the

length of the free layer.

denotes the

length of the free layer.  is the giant magnetoresistance ratio. According to Eq. 4.4,

the electrical conductance of the domain wall tunnel magnetoresistance (DW-TMR) memristor is obtained

as [137]

is the giant magnetoresistance ratio. According to Eq. 4.4,

the electrical conductance of the domain wall tunnel magnetoresistance (DW-TMR) memristor is obtained

as [137]

G(r) =  | = GP(r) + GAP(r) = rGH + (1 - r)GL | ||

| = (1 + rTMR)GL | (6.15) |

is the tunneling magnetoresistance ratio. The term

is the tunneling magnetoresistance ratio. The term  (

( ) is obtained

from Eq. 6.16 (Eq. 6.17) for the DW-GMR (DW-TMR) memristors, where

) is obtained

from Eq. 6.16 (Eq. 6.17) for the DW-GMR (DW-TMR) memristors, where  is the DW

velocity.

is the DW

velocity.

| (6.16) |

| (6.17) |

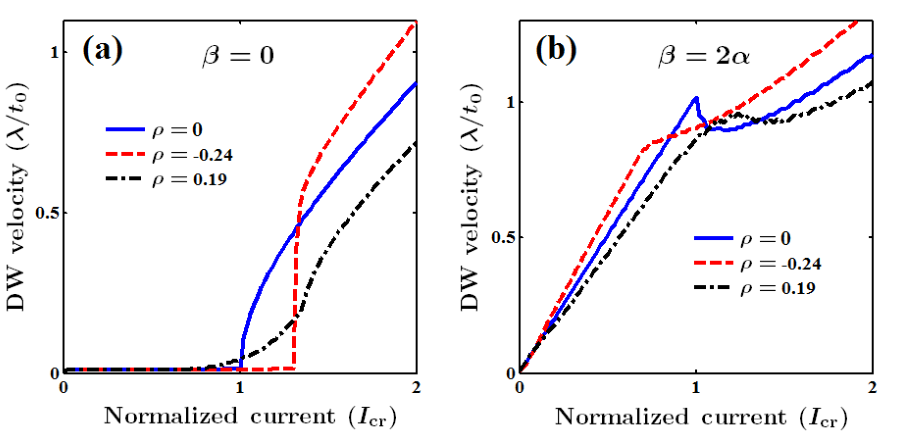

According to Eq. 6.16 (Eq. 6.17), in the DW-GMR (DW-TMR) memristor the term  (

( ) is a constant and thus is suited for charge- (flux)-based measurement, if there is a linear

relationship between the domain wall velocity (

) is a constant and thus is suited for charge- (flux)-based measurement, if there is a linear

relationship between the domain wall velocity ( ) and the current

) and the current  (voltage

(voltage  ). It

can be shown that a linear dependence of the DW velocity with respect to the applied current

or voltage is expected, when the ratio

). It

can be shown that a linear dependence of the DW velocity with respect to the applied current

or voltage is expected, when the ratio  is nonzero, where

is nonzero, where  is the damping parameter

and

is the damping parameter

and  defines the strength of the non-adiabatic spin-torque [174, 175]. In fact, for

defines the strength of the non-adiabatic spin-torque [174, 175]. In fact, for  the

DW exhibits a threshold current density required for current-induced motion, even when in the

absence of an extrinsic pinning [170, 176]. Thus, only in the presence of non-adiabatic spin-torque

(

the

DW exhibits a threshold current density required for current-induced motion, even when in the

absence of an extrinsic pinning [170, 176]. Thus, only in the presence of non-adiabatic spin-torque

( ), the DW-GMR and the DW-TMR memristors can be used for charge- and flux-based

sensing. In fact, the non-adiabatic spin-torque allows for a non-zero mobility of the DW where the

mobility is proportional to the ratio

), the DW-GMR and the DW-TMR memristors can be used for charge- and flux-based

sensing. In fact, the non-adiabatic spin-torque allows for a non-zero mobility of the DW where the

mobility is proportional to the ratio  [210, 211]. A comprehensive interpretation of the

non-adiabatic spin-torque expressed by

[210, 211]. A comprehensive interpretation of the

non-adiabatic spin-torque expressed by  is still subject to controversial discussions and there are

also difficulties to experimentally characterize

is still subject to controversial discussions and there are

also difficulties to experimentally characterize  [174, 212, 213, 214]. In [213] experimental

data shows

[174, 212, 213, 214]. In [213] experimental

data shows  ratios of

ratios of  and

and  for CoNi multilayers and FePt alloy thin films,

respectively.

for CoNi multilayers and FePt alloy thin films,

respectively.

| Figure 6.7.: | (a) Average domain wall velocity as a function of  . (b) Final relative domain wall position ( . (b) Final relative domain wall position ( ) as a

function of capacitance. ) as a

function of capacitance. |

As an example of a spintronic capacitance sensor, Fig. 6.7a shows the average DW velocity as a function of

the current passing through the DW-GMR memristor (connected in series to a capacitor as shown in

Fig. 6.1a) based on the one-dimensional model of DW dynamics explained in Section 4.2.2. According to

Eq. 6.16, the memristor is suited for capacitance sensing when  . Fig. 6.7b illustrates that when the

MC circuit (Fig. 6.1a) is excited by a step voltage the final domain wall position in the DW-GMR memristor

and thus the memristance value is a function of the capacitance value. The sensitivity increases with

the ratio

. Fig. 6.7b illustrates that when the

MC circuit (Fig. 6.1a) is excited by a step voltage the final domain wall position in the DW-GMR memristor

and thus the memristance value is a function of the capacitance value. The sensitivity increases with

the ratio  , but at the cost of decreased sensing range. In fact, the increase in the ratio

, but at the cost of decreased sensing range. In fact, the increase in the ratio

, increases the DW velocity and thus the sensitivity. It should be noted that for

, increases the DW velocity and thus the sensitivity. It should be noted that for  , the

DW propagation is characterized by a linear regime and a nonlinear regime above the Walker

breakdown [215, 174, 216]. Above a critical current value called the Walker breakdown, the DW motion

becomes non-uniform (oscillatory) which is unfavorable for memristive sensing as discussed in the

following.

, the

DW propagation is characterized by a linear regime and a nonlinear regime above the Walker

breakdown [215, 174, 216]. Above a critical current value called the Walker breakdown, the DW motion

becomes non-uniform (oscillatory) which is unfavorable for memristive sensing as discussed in the

following.

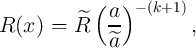

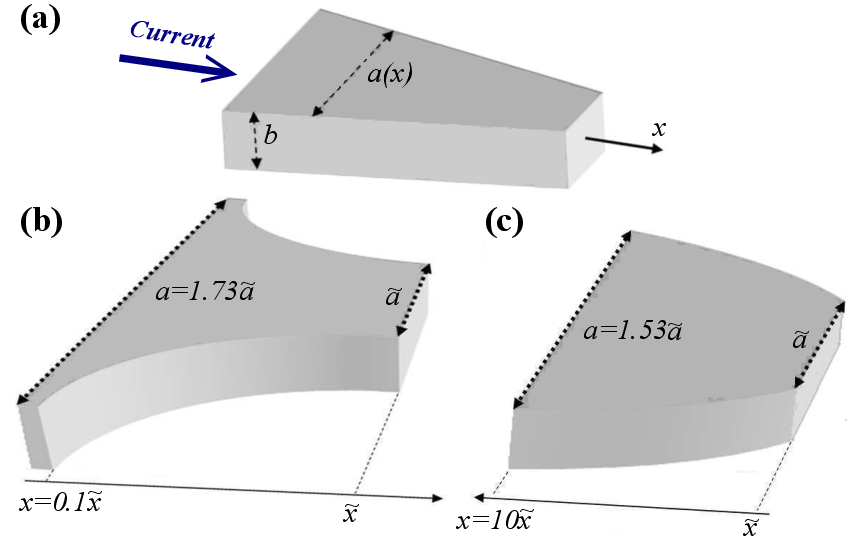

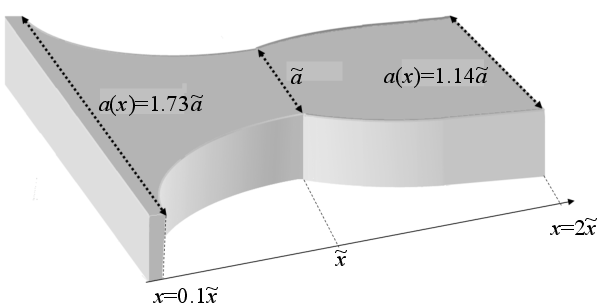

The dynamic properties of a propagating magnetic DW are strongly affected by the device geometry [217]. A

magnetic thin-film (MTF) element with varying width  and constant thickness

and constant thickness  (Fig. 6.8a) has been

proposed as a spintronic (DW-MTF) memristor [61] based upon the STT-induced DW motion in the

film-length direction

(Fig. 6.8a) has been

proposed as a spintronic (DW-MTF) memristor [61] based upon the STT-induced DW motion in the

film-length direction  . The reaction force exerted by the domain wall to the electrons acts as the wall

resistance [61]. The current-induced DW motion exhibits memristive properties, when the thin-film aspect

ratio

. The reaction force exerted by the domain wall to the electrons acts as the wall

resistance [61]. The current-induced DW motion exhibits memristive properties, when the thin-film aspect

ratio  is varying with

is varying with  . Indeed, when the thickness of the device is fixed, the mobility of the DW

and thus the electrical resistance of the device, becomes a function of the thin-film element width

. Indeed, when the thickness of the device is fixed, the mobility of the DW

and thus the electrical resistance of the device, becomes a function of the thin-film element width  and

is expressed as [61]

and

is expressed as [61]

| (6.18) |

where  and

and  are the resistance and the width of the element, respectively, when the DW is located at

are the resistance and the width of the element, respectively, when the DW is located at

and

and  determines the DW mobility scaling with the aspect ratio as

determines the DW mobility scaling with the aspect ratio as  [61]. Therefore,

when the spatial dependence of the element width as a function of the DW position is given

by

[61]. Therefore,

when the spatial dependence of the element width as a function of the DW position is given

by

| (6.19) |

the  characteristics of the device is obtained as

characteristics of the device is obtained as

| (6.20) |

where we have [61]

| (6.21) |

Since the dynamics of the magnetic domain wall motion ( ) is a function of

) is a function of  and current density

(

and current density

( ), the latter equation shows that this device is a memristive system (Eq. 2.14 and Eq. 2.15). For

an idealistic case in which the DW velocity is proportional to the current density, the

), the latter equation shows that this device is a memristive system (Eq. 2.14 and Eq. 2.15). For

an idealistic case in which the DW velocity is proportional to the current density, the  and

and  constitutive relations of the domain wall magnetic thin-film (DW-MTF) memristor are determined

as [61]

constitutive relations of the domain wall magnetic thin-film (DW-MTF) memristor are determined

as [61]

| (6.22) |

and

| (6.23) |

| Figure 6.8.: | (a) Domain wall magnetic thin-film (DW-MTF) spintronic memristor with appropriate geometries for (b) charge-based and (c) flux-based sensing. |

where  and

and  are constant coefficients and

are constant coefficients and  determines the spatial dependence of the element’s width

on

determines the spatial dependence of the element’s width

on  (Eq. 6.19) [61, 172]. According to Eq. 2.10 (Eq. 2.11) and Eq. 6.22 (Eq. 6.23), for charge

(flux)-controlled DW-MTF memristor we obtain

(Eq. 6.19) [61, 172]. According to Eq. 2.10 (Eq. 2.11) and Eq. 6.22 (Eq. 6.23), for charge

(flux)-controlled DW-MTF memristor we obtain

| (6.24) |

and

| (6.25) |

Therefore, in order to keep the terms  and

and  fixed, the appropriate device geometries for

charge- and flux-based memristive sensing methods are (uniquely) determined by

fixed, the appropriate device geometries for

charge- and flux-based memristive sensing methods are (uniquely) determined by

| (6.26) |

and

| (6.27) |

In fact, different device geometries can provide different memristive behaviors required for various sensing

applications. With a spatial shape of  (

( ), the DW-MTF memristor is suited

for charge (flux)-based sensing. Fig. 6.8 shows schematic geometries for memristive sensing where the

parameter

), the DW-MTF memristor is suited

for charge (flux)-based sensing. Fig. 6.8 shows schematic geometries for memristive sensing where the

parameter  is supposed equal to

is supposed equal to  [172].

[172].

| Figure 6.9.: | (a) DW-MTF memristor  curves. (b) The current flowing through the inductor and (c) the memductance

as a function of time. (d) The electric circuit for flux-based inductance sensing and the obtained inductances by using

Eq. 6.9. curves. (b) The current flowing through the inductor and (c) the memductance

as a function of time. (d) The electric circuit for flux-based inductance sensing and the obtained inductances by using

Eq. 6.9. |

Fig. 6.9 shows an example of inductance sensing by using the DW-MTF memristor with proper geometry

based on Eq. 6.9. The applied current is  and all axes are dimensionless, with current,

memductance, voltage, time, and angular frequency normalized in units of

and all axes are dimensionless, with current,

memductance, voltage, time, and angular frequency normalized in units of  ,

,  ,

,  ,

,  ,

and

,

and  .

.  is the memductance when the domain wall position is

is the memductance when the domain wall position is  and

and  is equal to

is equal to

. According to Fig. 6.9a, the memristor shows different memristive behavior for different

inductances connected in parallel. Therefore, by using Eq. 6.9 (Fig. 6.9d), the amount of inductance

can be calculated when the current (Fig. 6.9b) and memductance (Fig. 6.9c) modulations are

known.

. According to Fig. 6.9a, the memristor shows different memristive behavior for different

inductances connected in parallel. Therefore, by using Eq. 6.9 (Fig. 6.9d), the amount of inductance

can be calculated when the current (Fig. 6.9b) and memductance (Fig. 6.9c) modulations are

known.

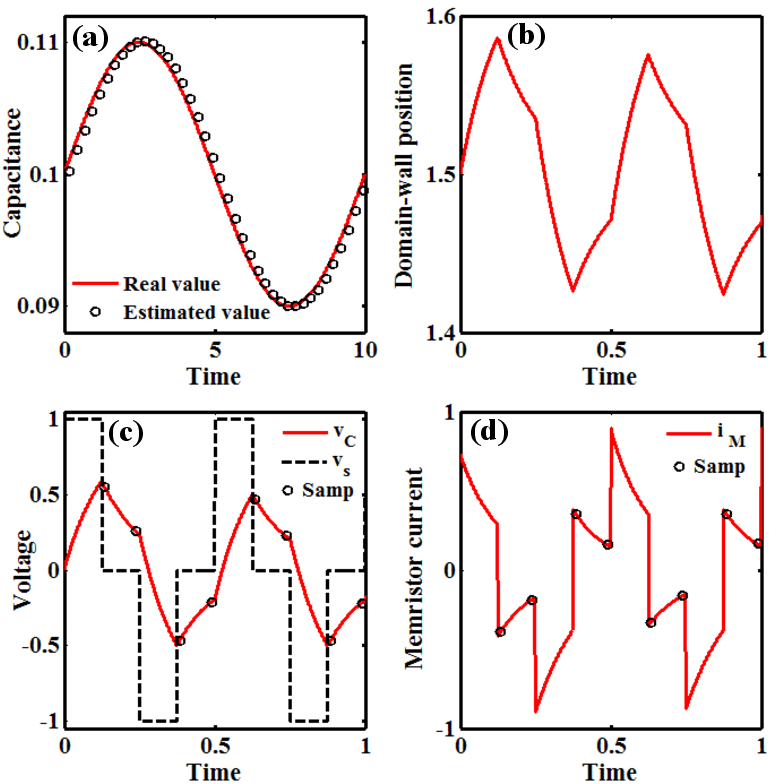

| Figure 6.10.: | (a) Time-varying capacitance and memristive measurement results. (b) The domain wall position and (c)

the source voltage  and the voltage across the capacitor and the voltage across the capacitor  and (d) the current flowing through the memristor and (d) the current flowing through the memristor  with respect to time.

with respect to time. |

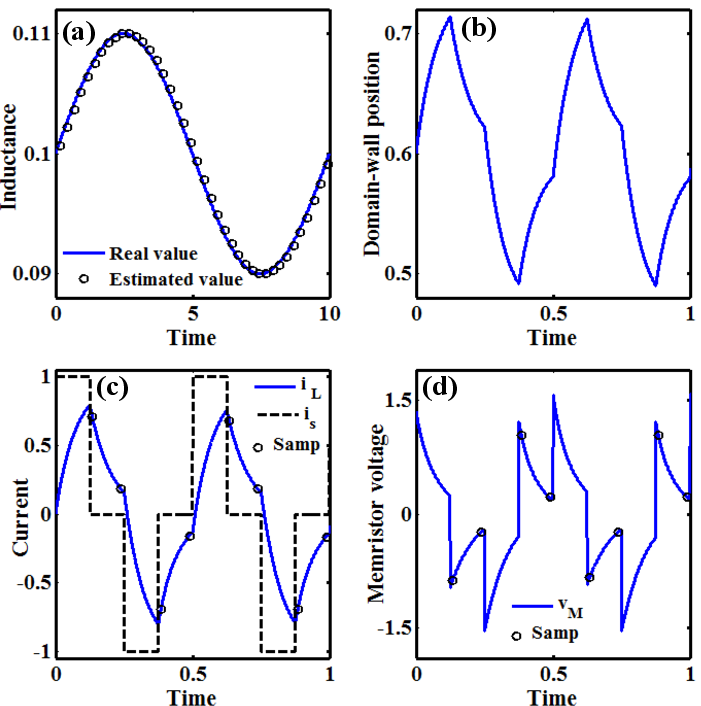

| Figure 6.11.: | (a) Time-varying inductance and memristive measurement results. (b) The domain wall position and (c)

the source current  and the current flowing through the inductor and the current flowing through the inductor  and (d) the voltage of the memristor and (d) the voltage of the memristor  with

respect to time. with

respect to time. |

| Figure 6.12.: | Proposed DW-MTF memristor structure for simultaneous capacitance and inductance sensing. |

Fig. 6.10 and Fig. 6.11 show the simulation results for memristive measurement of time-varying capacitors

and inductors. The voltage  and current

and current  sources are pulse trains with a 50% duty cycle and a

magnitude of

sources are pulse trains with a 50% duty cycle and a

magnitude of  and

and  and the capacitance and inductance are normalized by

and the capacitance and inductance are normalized by  and

and  ,

respectively.

,

respectively.  (

( ) is equal to

) is equal to  (

( ), where

), where  (

( ) corresponds to the memristance

(memductance) when domain wall is located at

) corresponds to the memristance

(memductance) when domain wall is located at  . By sampling

. By sampling  and

and  the capacitance

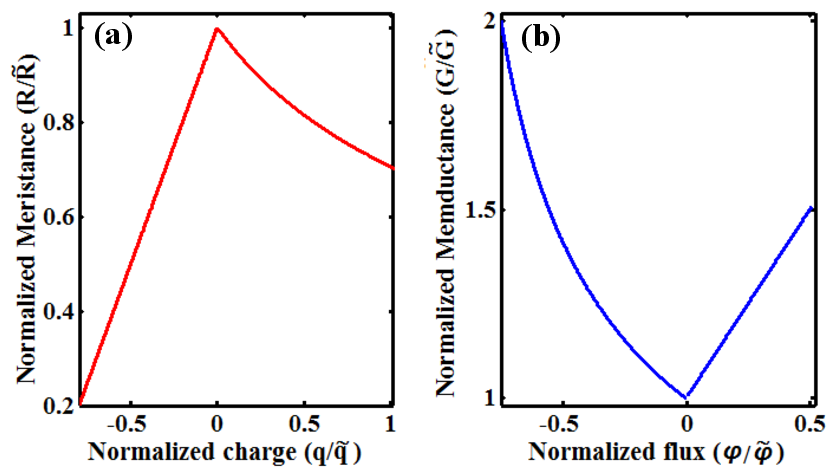

(inductance) can be calculated using Eq. 6.4 (Eq. 6.9). Fig. 6.12 shows a DW-MTF memristor

structure suited for both capacitance and inductance sensing. The term

the capacitance

(inductance) can be calculated using Eq. 6.4 (Eq. 6.9). Fig. 6.12 shows a DW-MTF memristor

structure suited for both capacitance and inductance sensing. The term  (

( ) is

constant for

) is

constant for  (

( ) and the corresponding memristance and memductance are shown in

Fig. 6.13.

) and the corresponding memristance and memductance are shown in

Fig. 6.13.

| Figure 6.13.: | (a)  as a function of charge and (b) as a function of charge and (b)  as a function of flux for the DW-MTF memristor structure

shown in Fig. 6.12. as a function of flux for the DW-MTF memristor structure

shown in Fig. 6.12. |

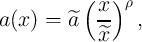

In order to take a closer look at the DW dynamics in a patterned structure, the one-dimensional

model of DW dynamics (Section 4.2.2) is employed to analyze the DW-MTF-based memristive

sensing. The dynamic properties of a propagating magnetic DW are strongly affected by the device

geometry [217]. The varying width of the DW-MTF element (Fig. 6.12) is taken into account by

assuming the current density and the number of spins ( ) in the DW [170] as a

function of the DW position

) in the DW [170] as a

function of the DW position  . Therefore, Eq. 4.8 is solved for

. Therefore, Eq. 4.8 is solved for  and

and

.

.

| Figure 6.14.: | Time-averaged domain wall velocity (a) in the absence and (b) in the presence of the non-adiabatic

spin-torque effect plotted for different geometrical structures ( ). ). |

Fig. 6.14 shows the geometry dependence of the DW dynamics for zero and nonzero non-adiabatic

spin-torque values. In the absence of the non-adiabatic term (Fig. 6.14a), there is a geometry dependent

threshold current required to move a DW. Therefore, for the currents below a current threshold the

memristive behavior can not be observed. In the presence of the non-adiabatic term (Fig. 6.14b), the average

DW velocity increases linearly with the applied current for low current values. Therefore, with

, the memristive behavior is observed and with proper geometry, the device can be used for

memristive sensing. Above a (geometry dependent) critical current corresponding to the Walker

breakdown [215, 174, 216], the DW motion shows complex behaviors. Therefore, the memristive sensing has

to be performed in a low current regime, which for a given sensing resolution, increases the sensing

time.

, the memristive behavior is observed and with proper geometry, the device can be used for

memristive sensing. Above a (geometry dependent) critical current corresponding to the Walker

breakdown [215, 174, 216], the DW motion shows complex behaviors. Therefore, the memristive sensing has

to be performed in a low current regime, which for a given sensing resolution, increases the sensing

time.