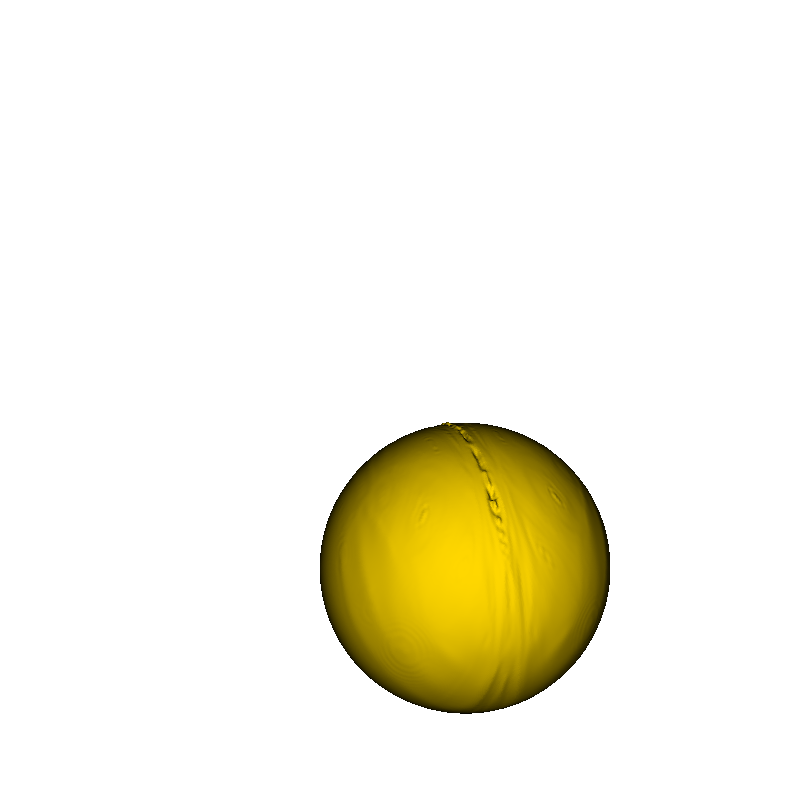

A Supplementary Material 1

In the following, the results for the test cases in Chapter 3 are provided for various resolutions.

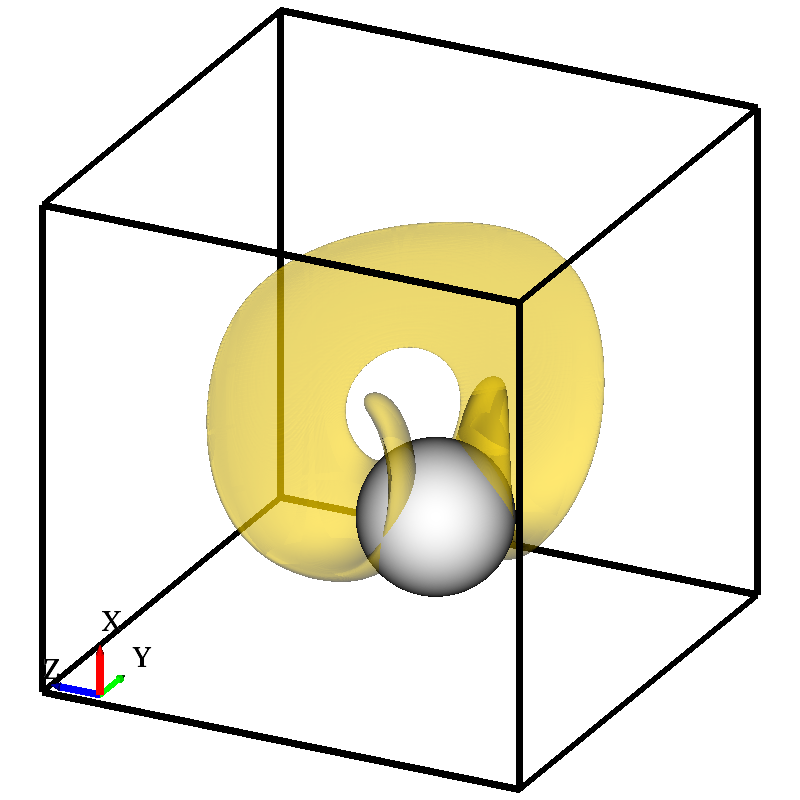

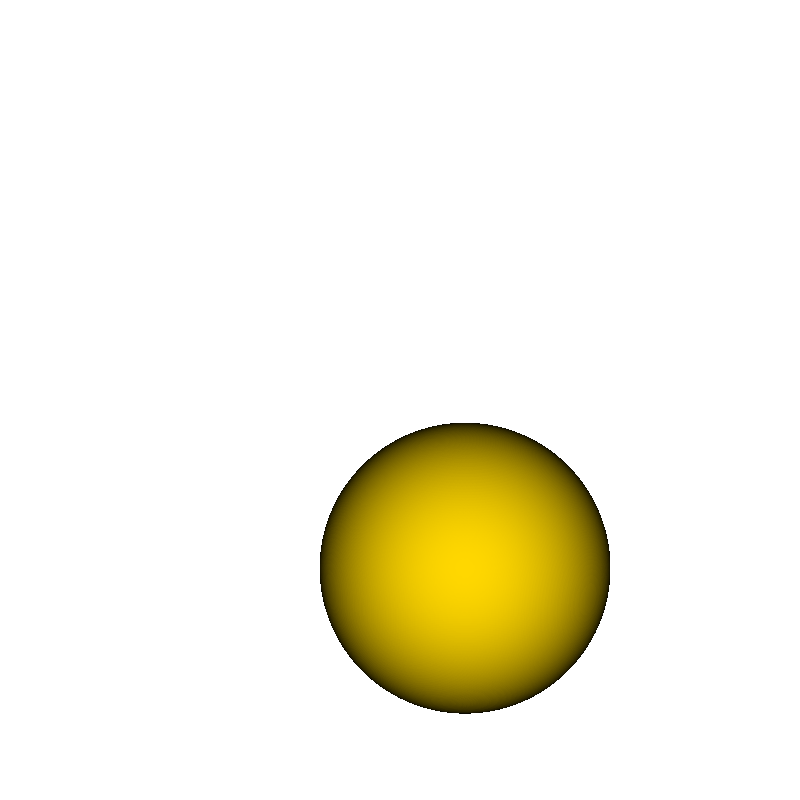

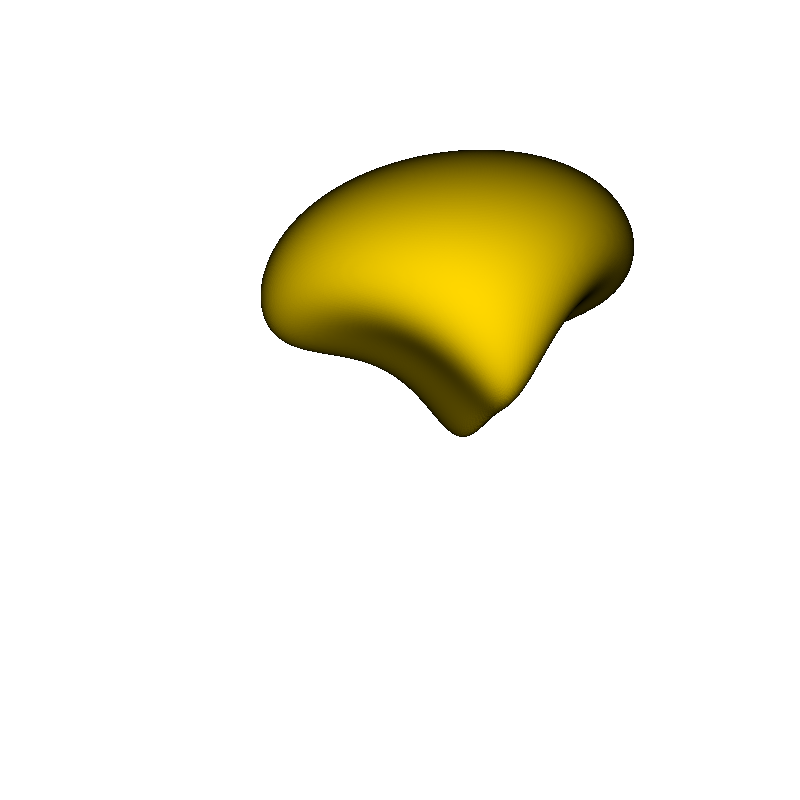

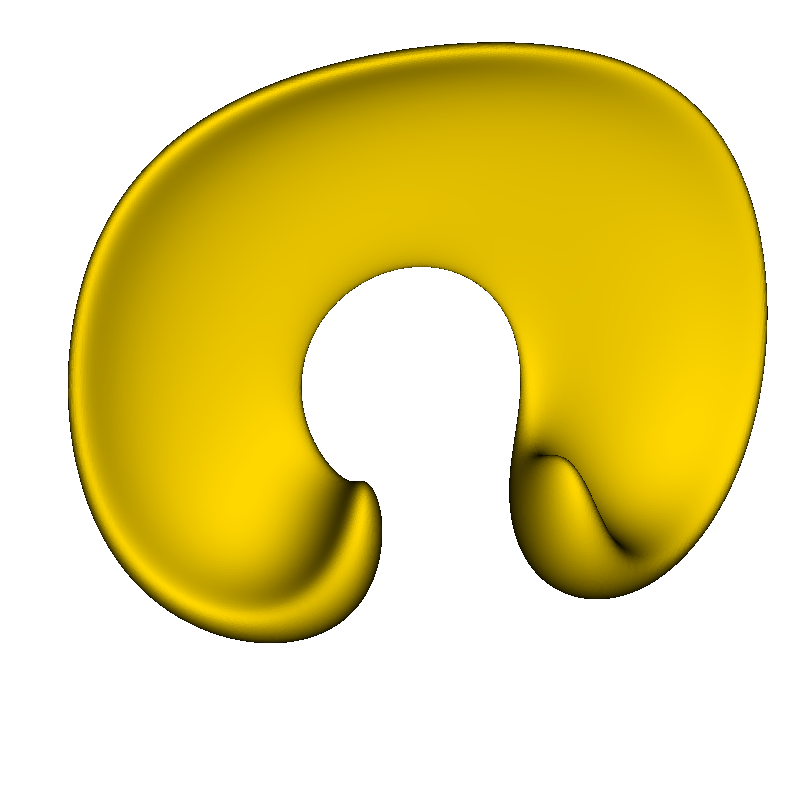

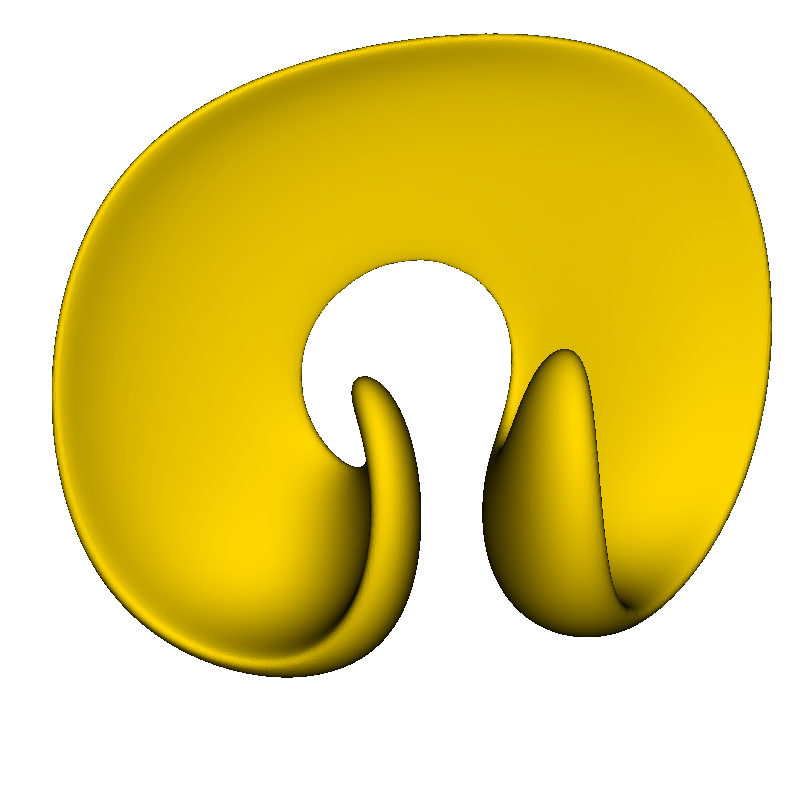

A.1 Enright Test

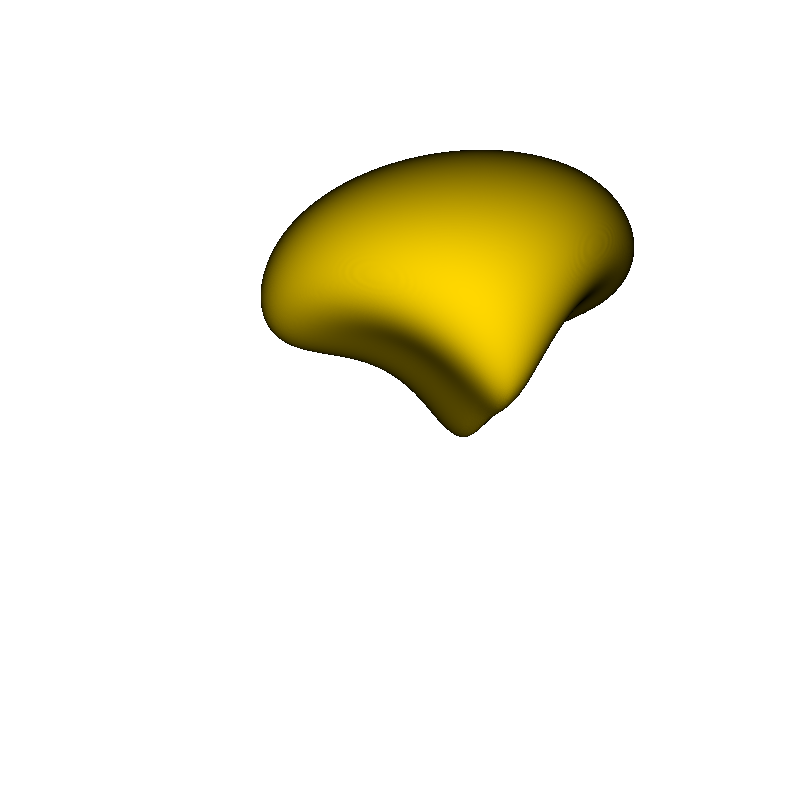

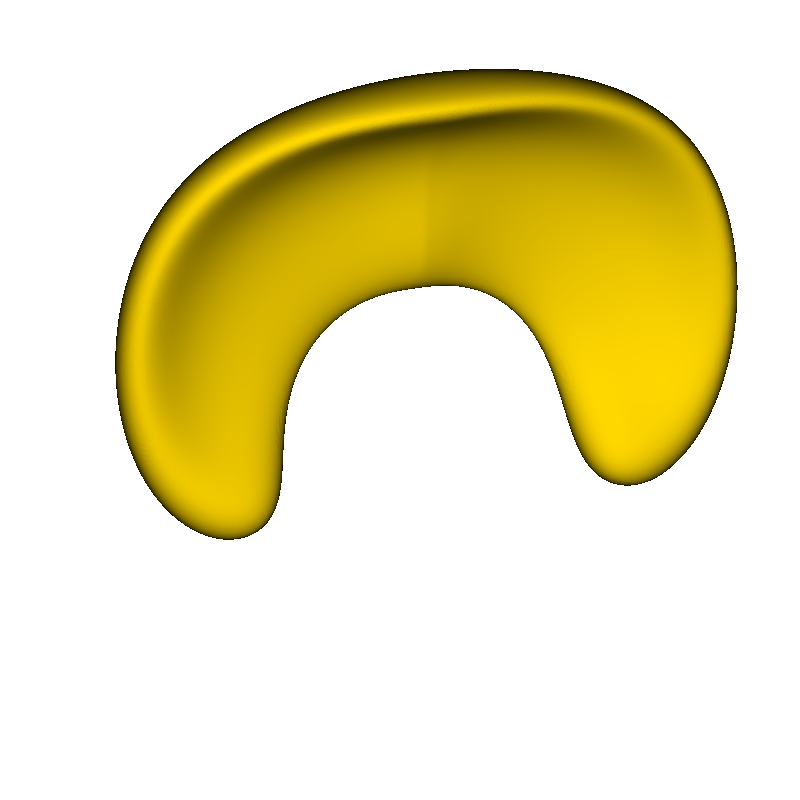

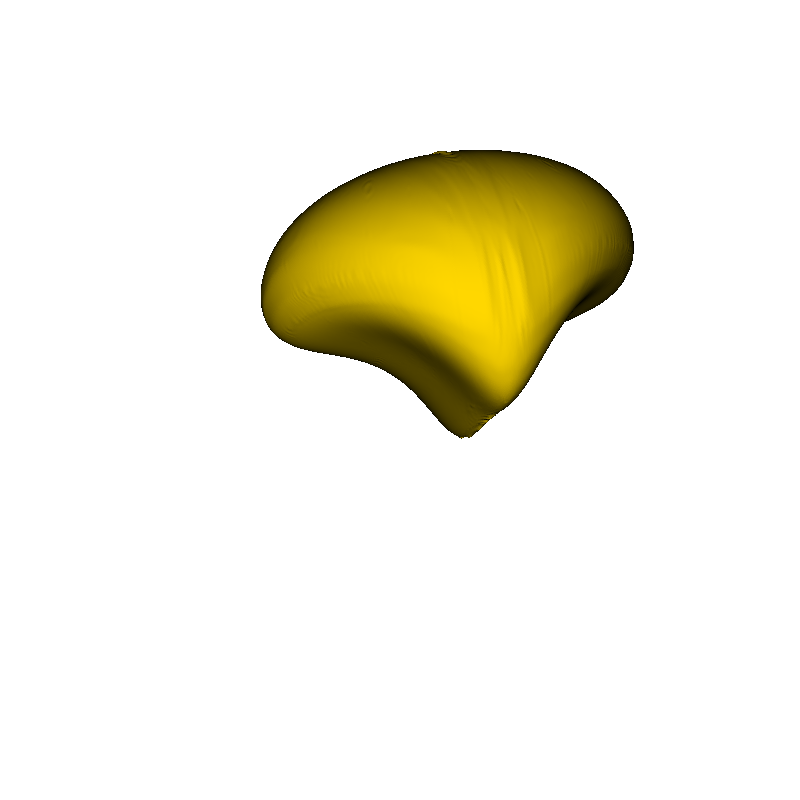

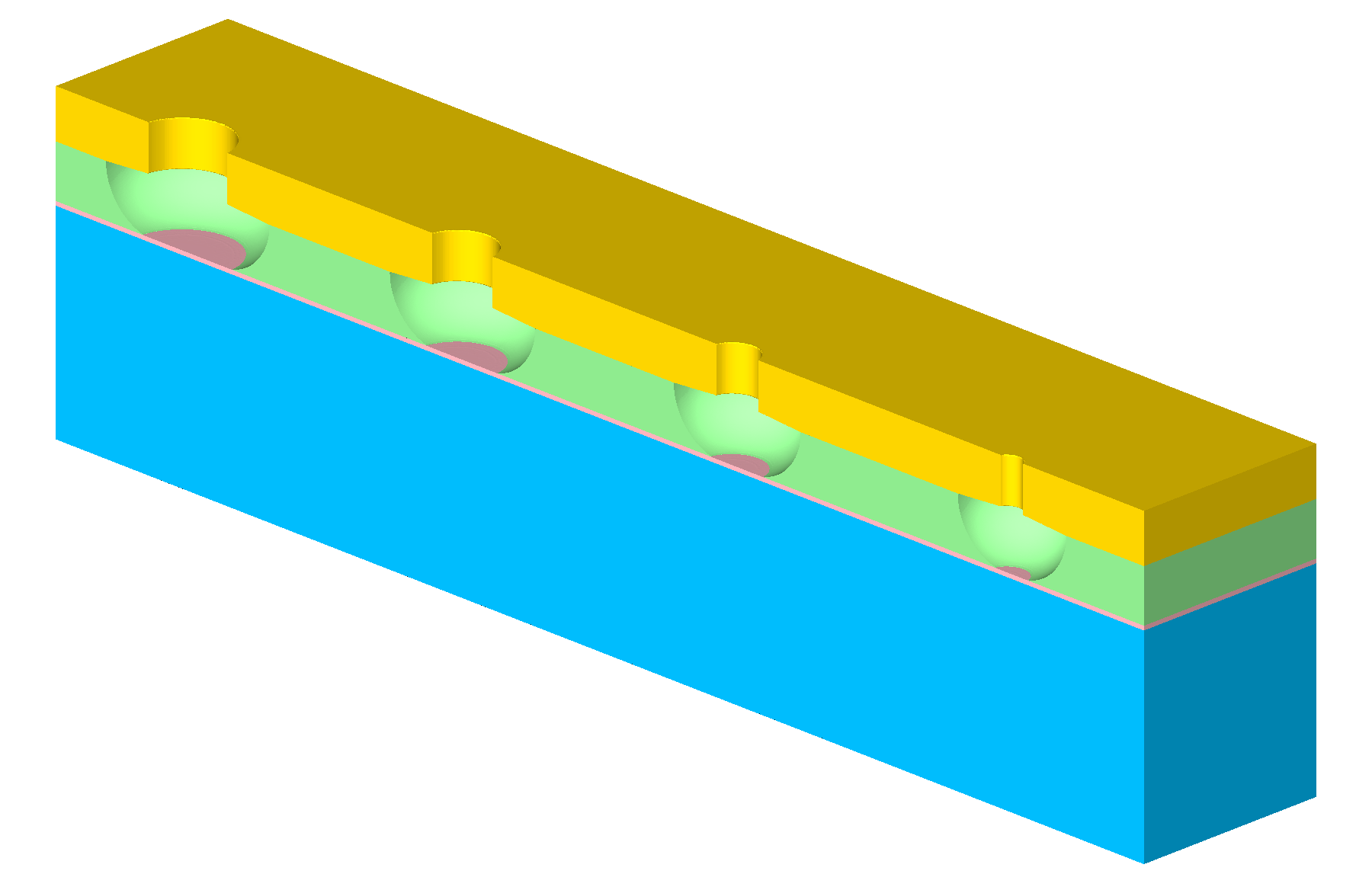

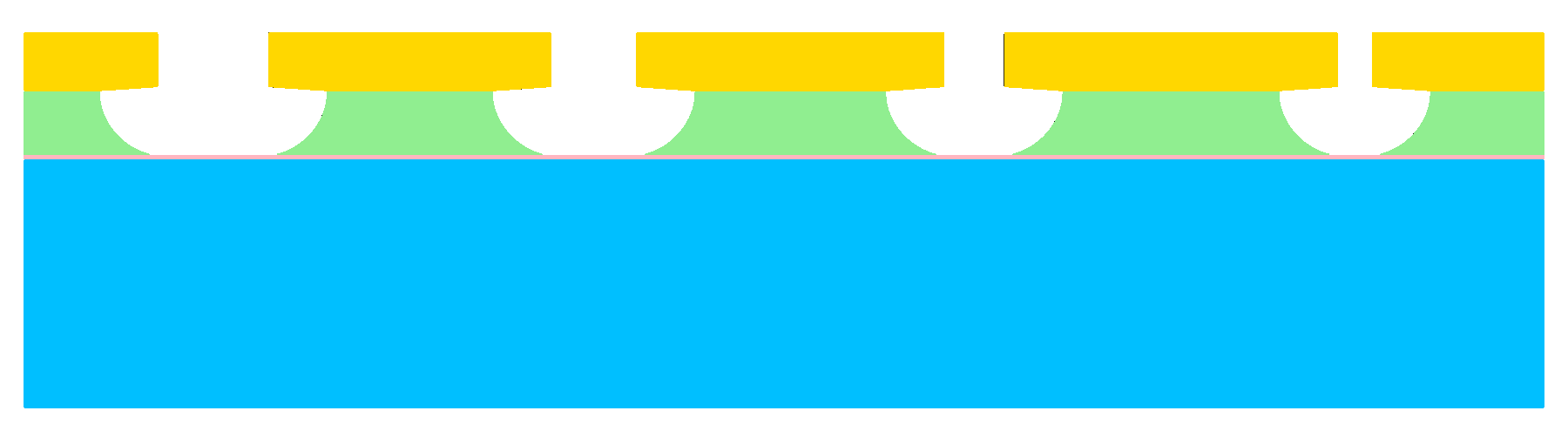

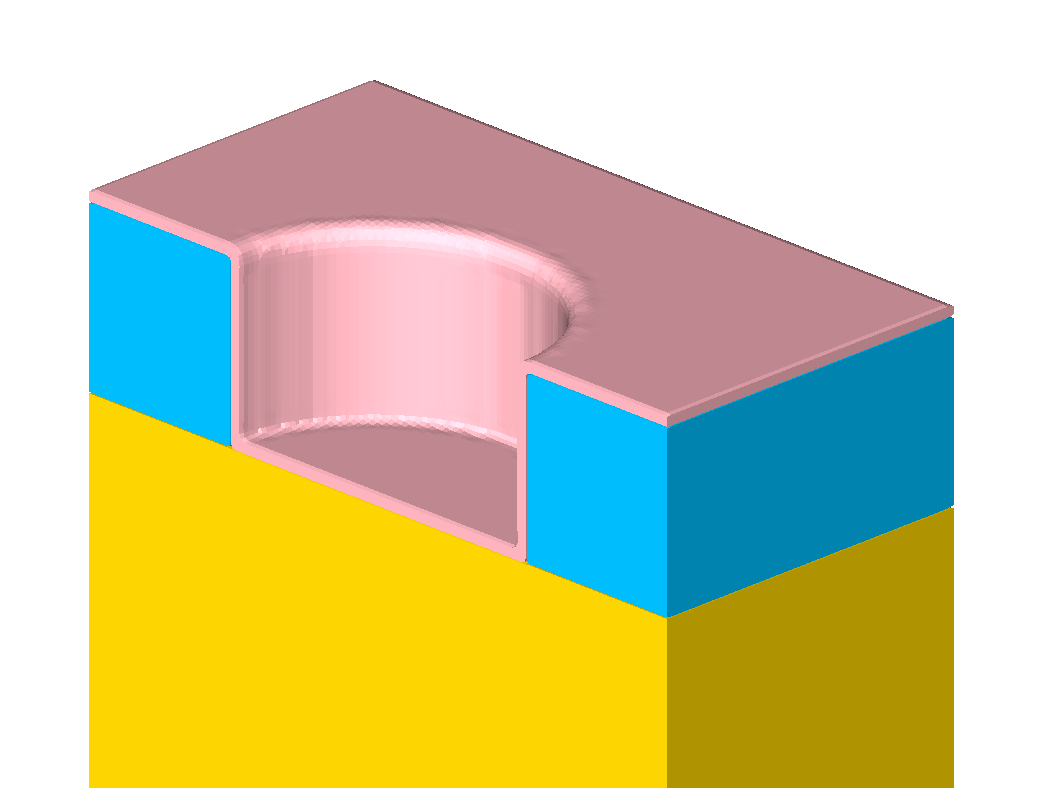

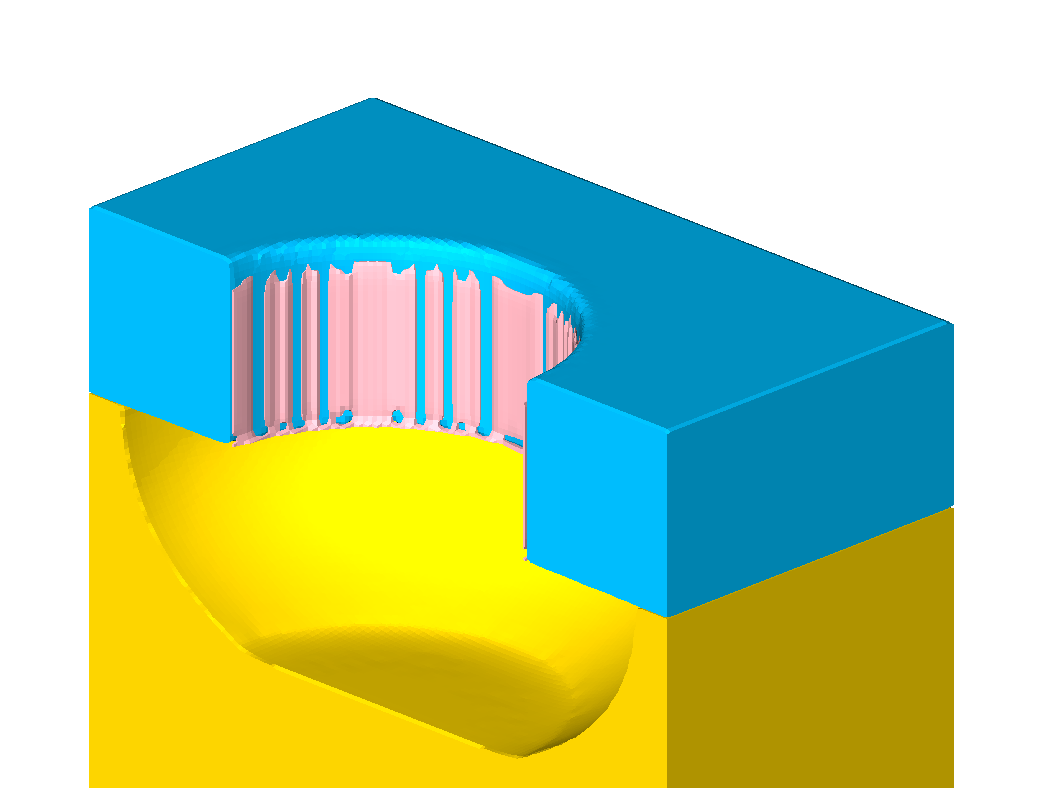

A.2 Material Dependent Isotropic Etching

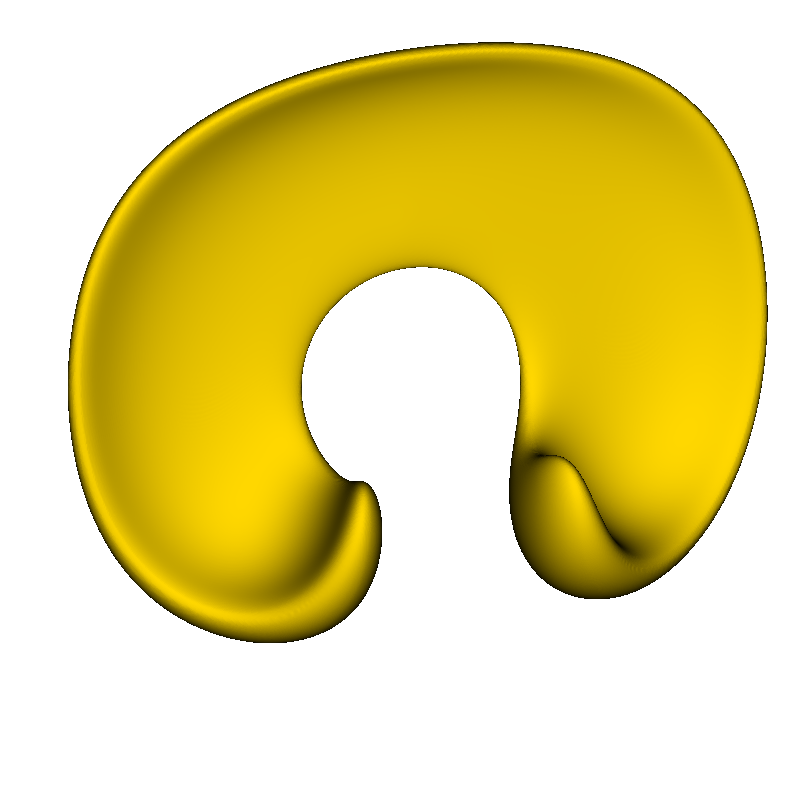

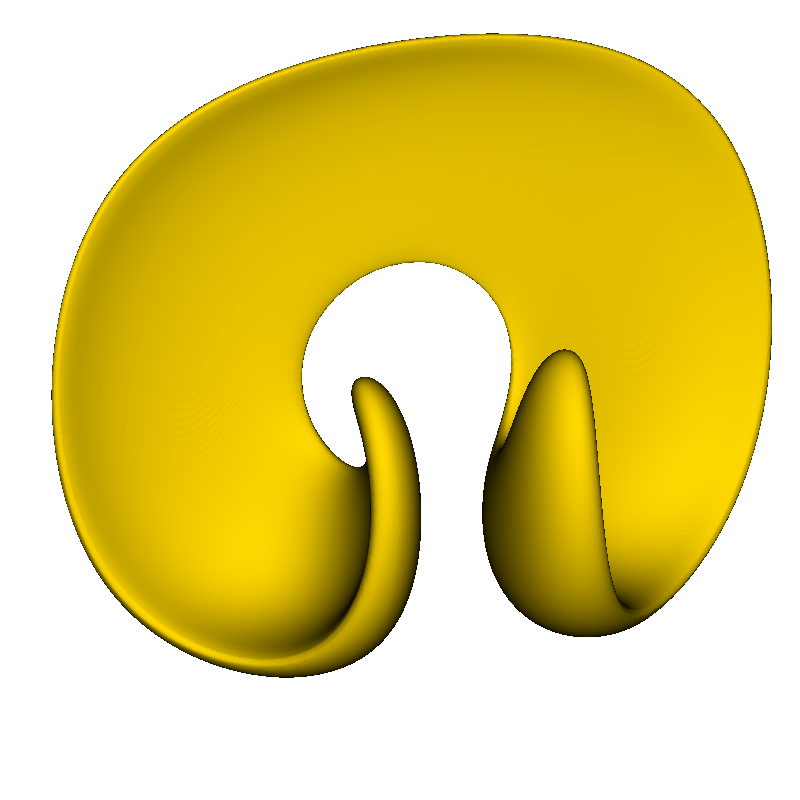

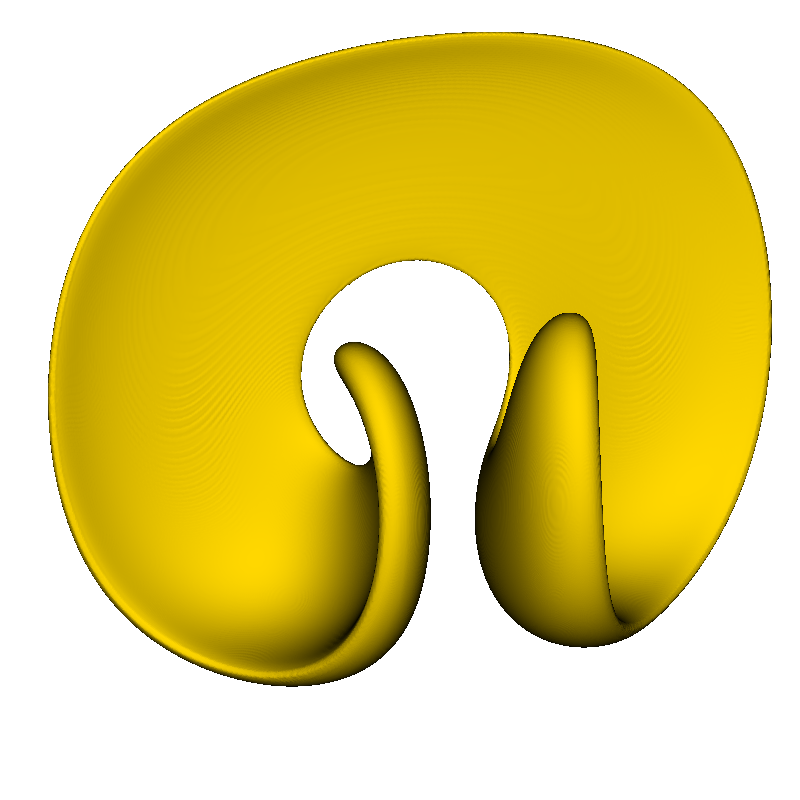

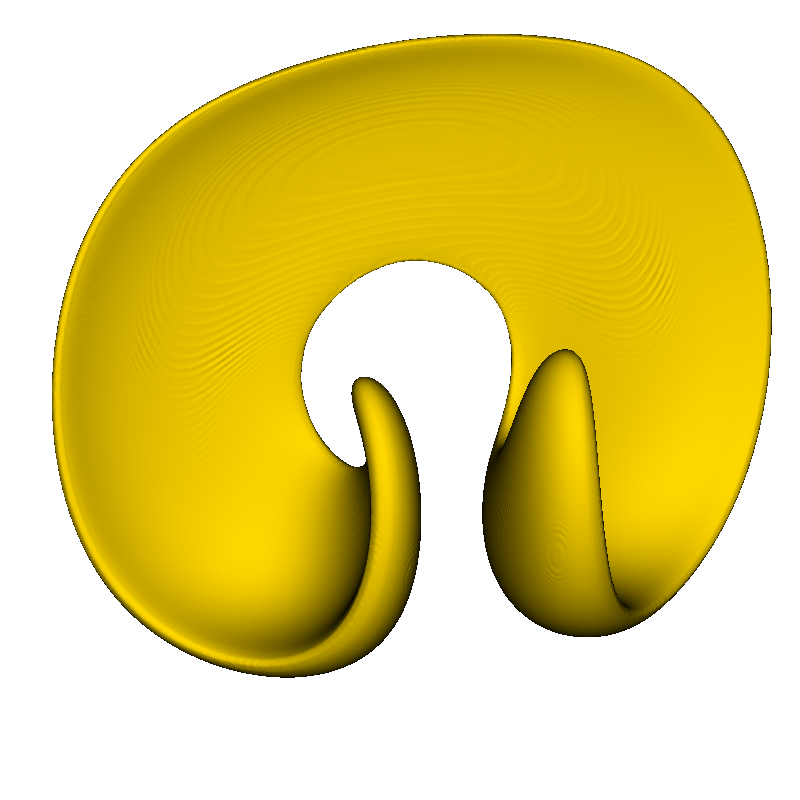

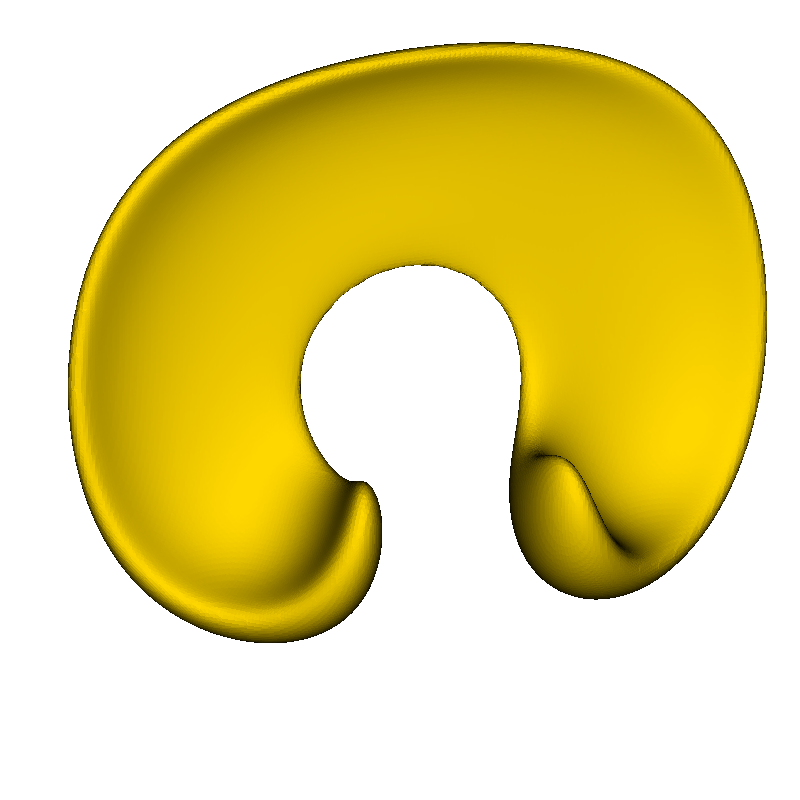

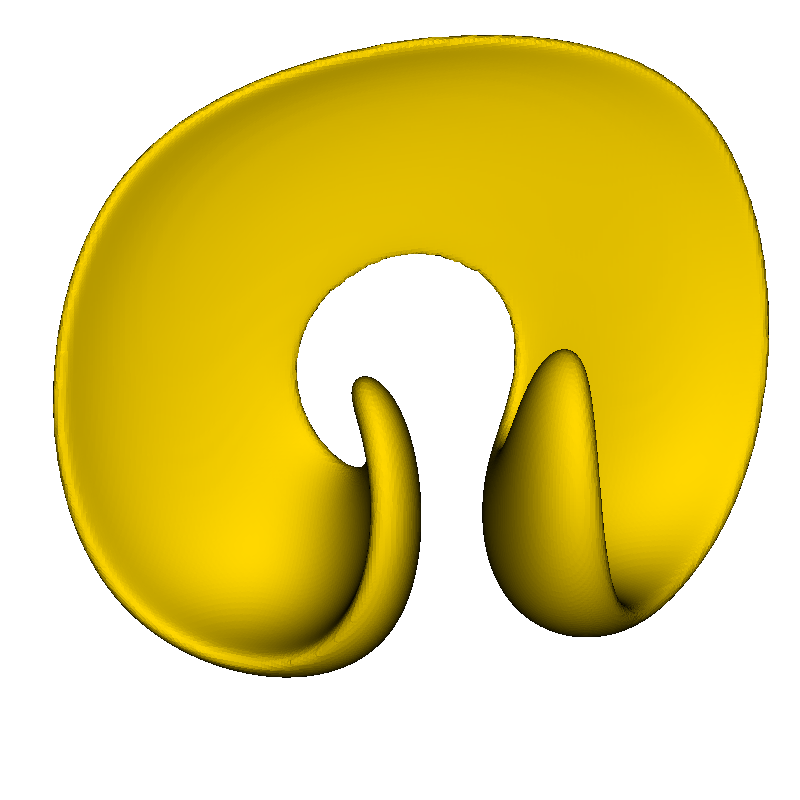

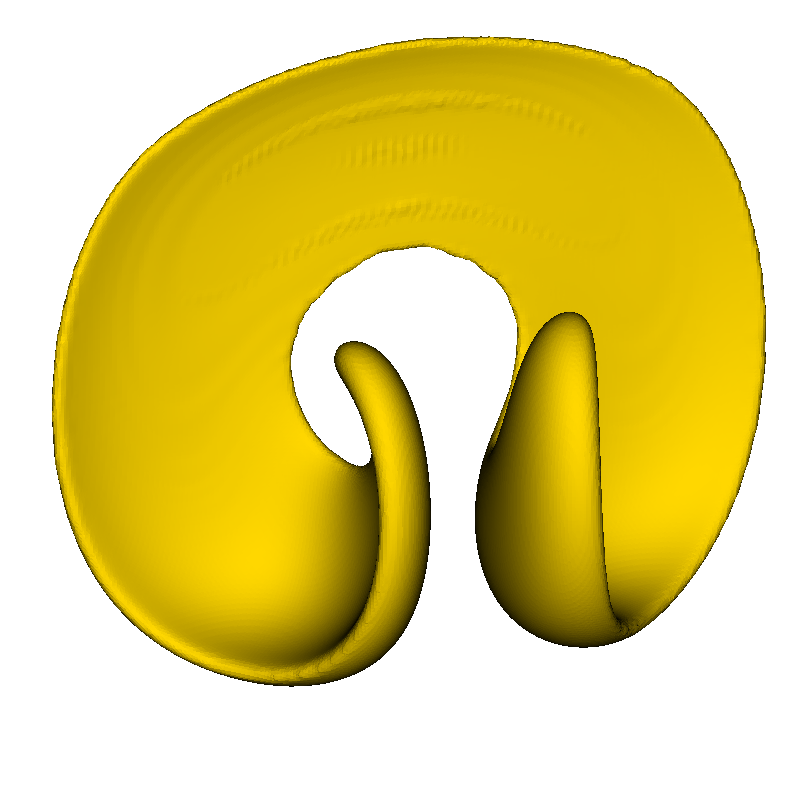

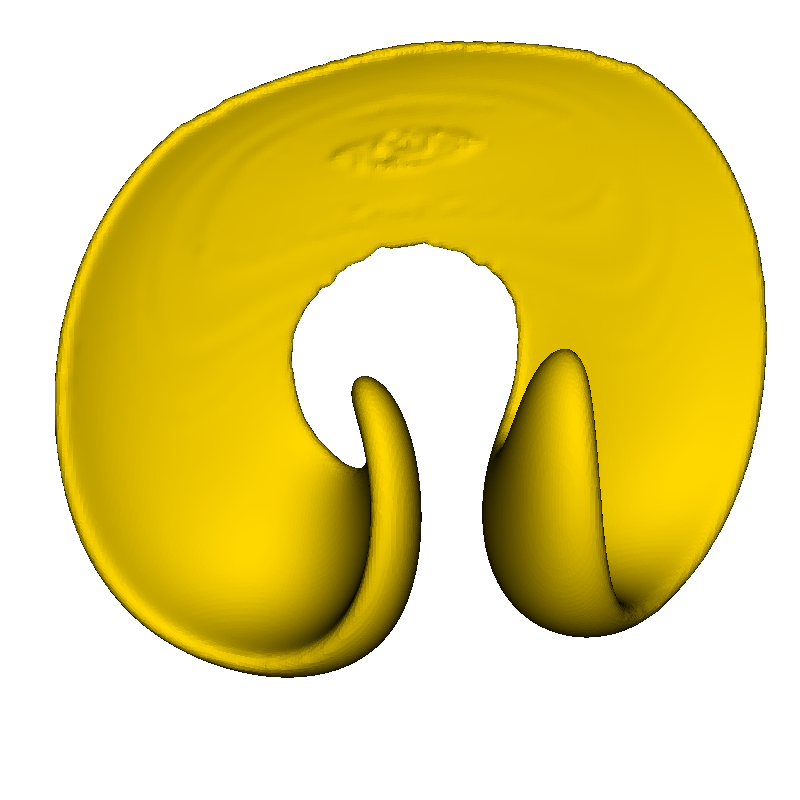

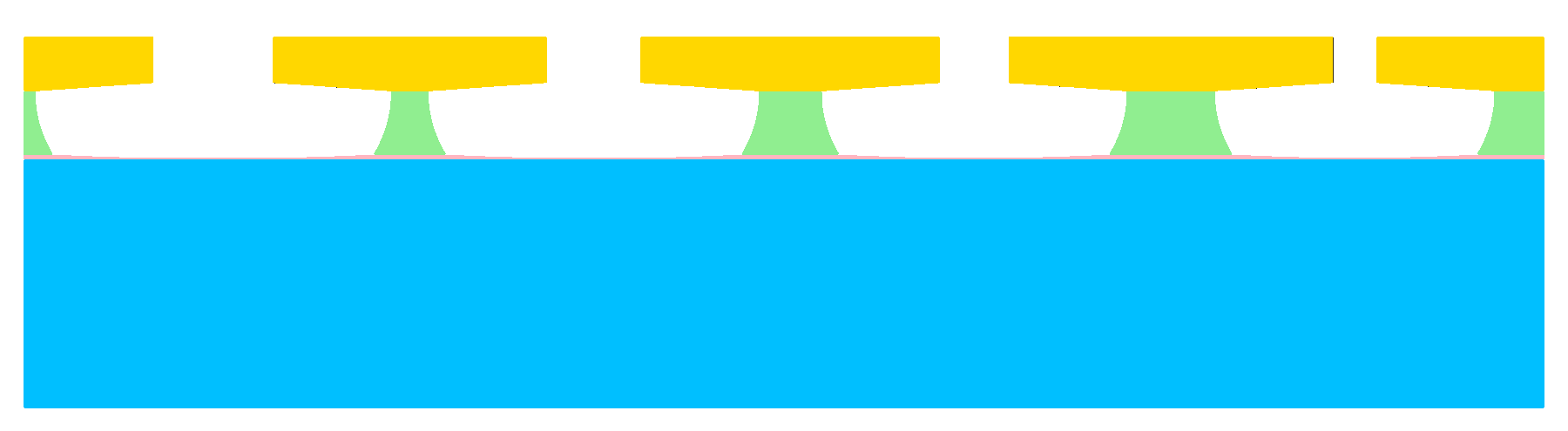

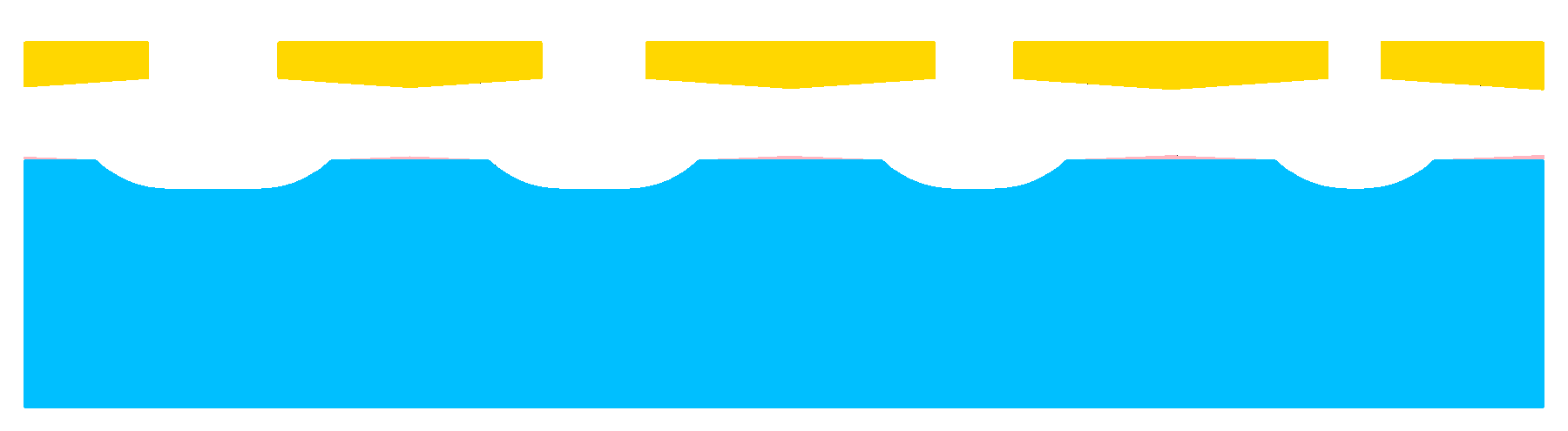

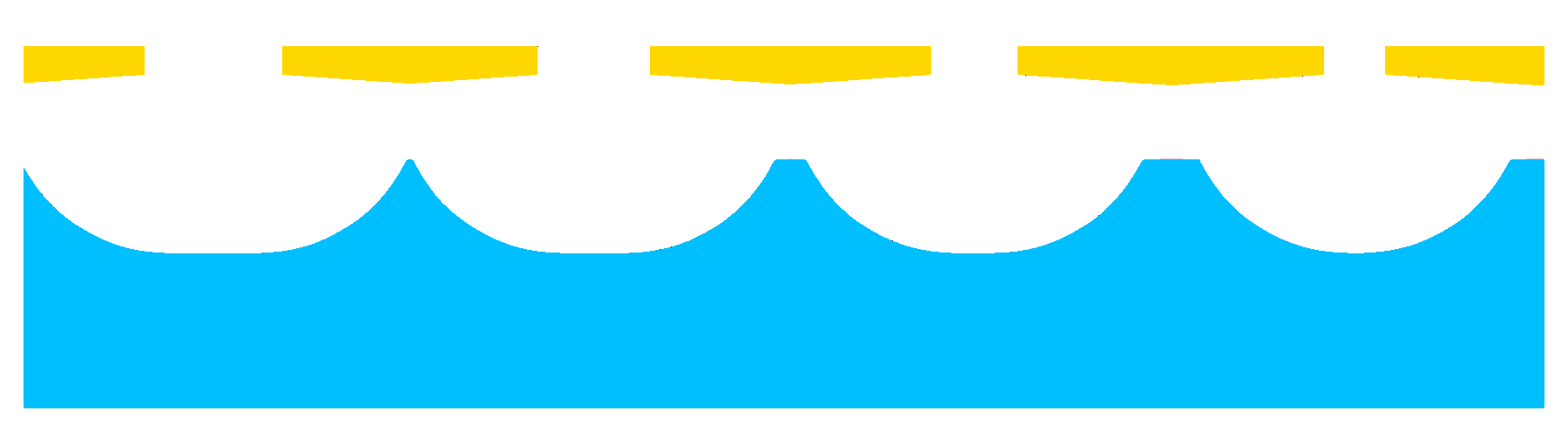

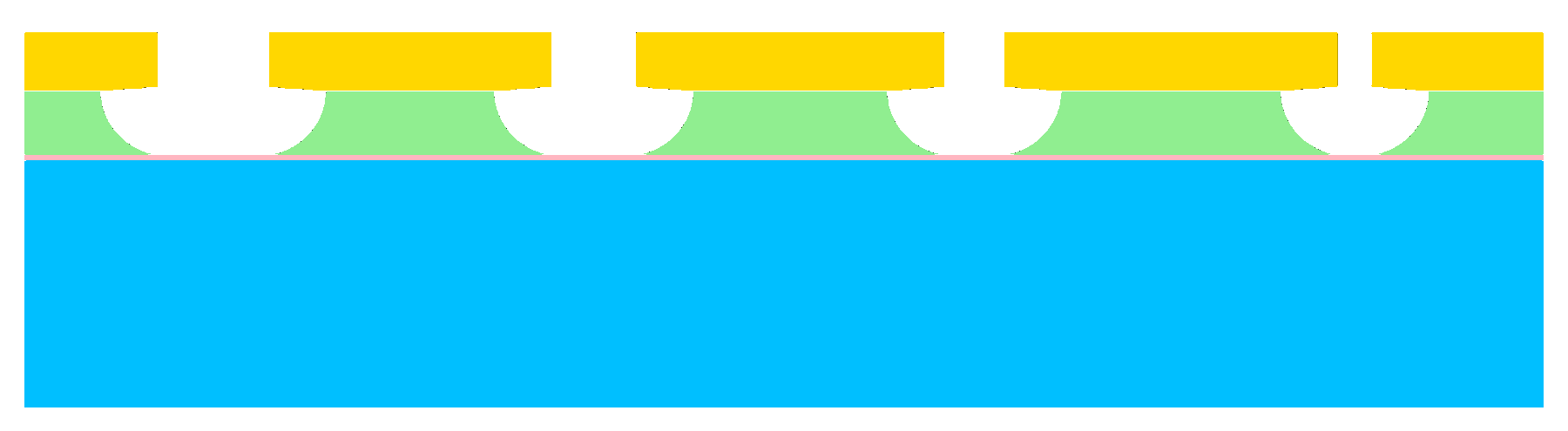

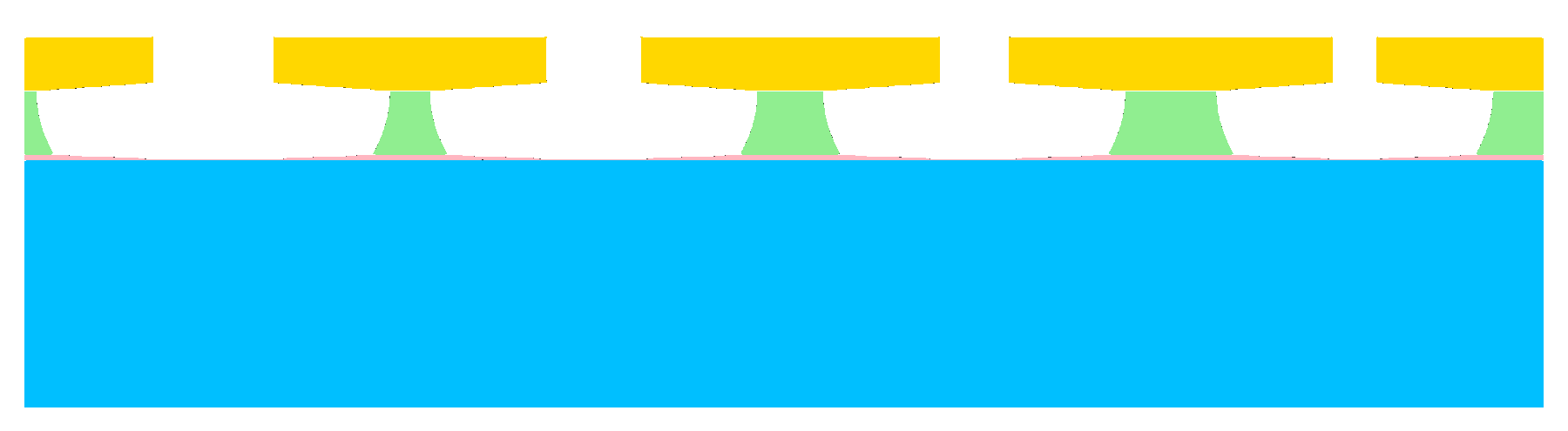

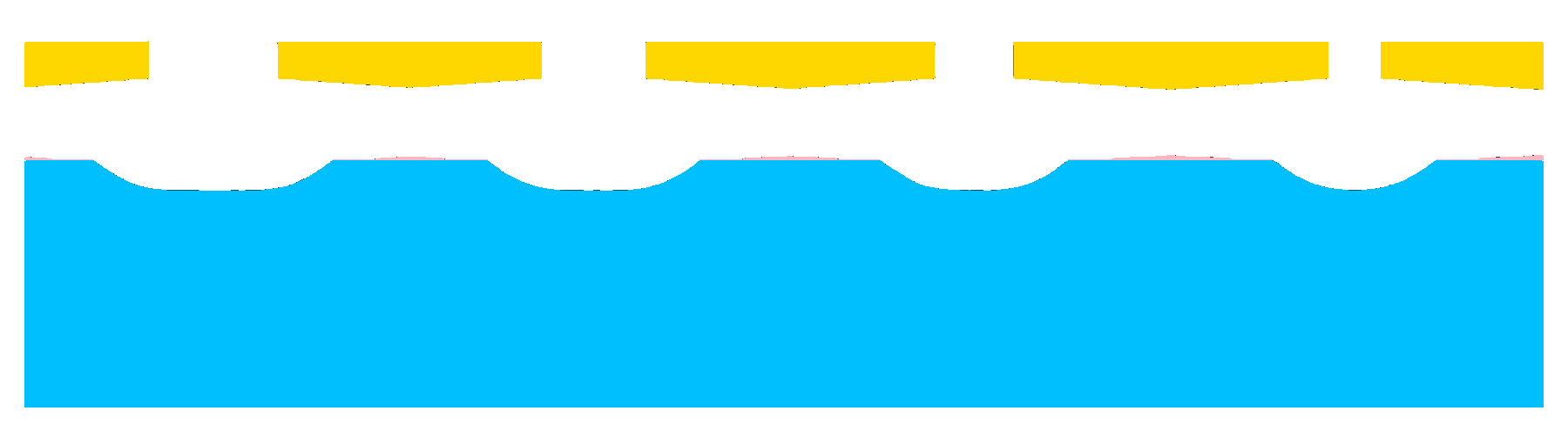

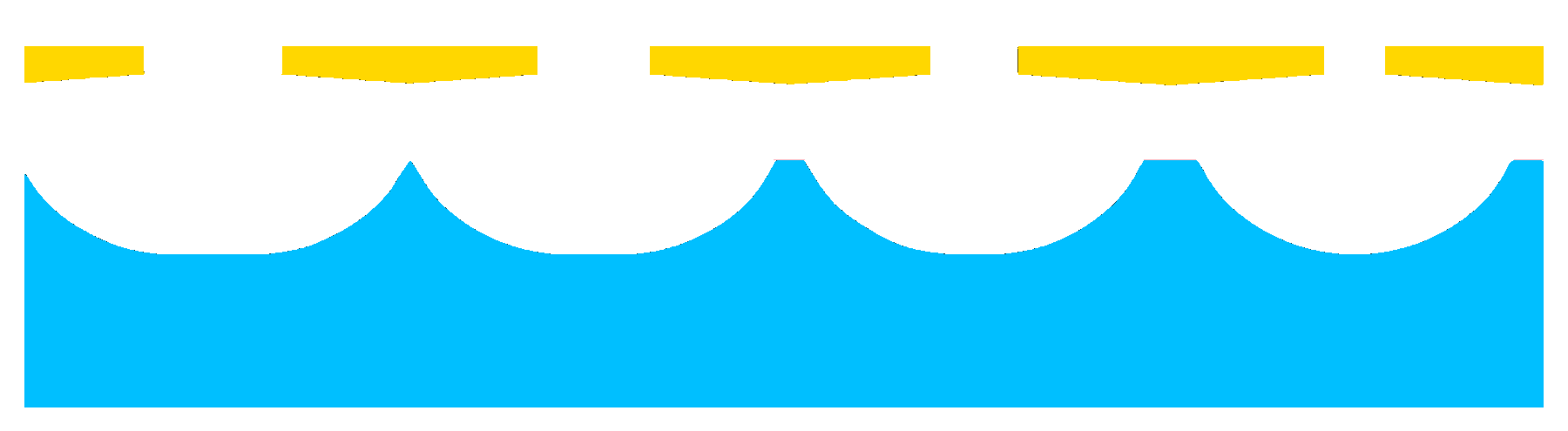

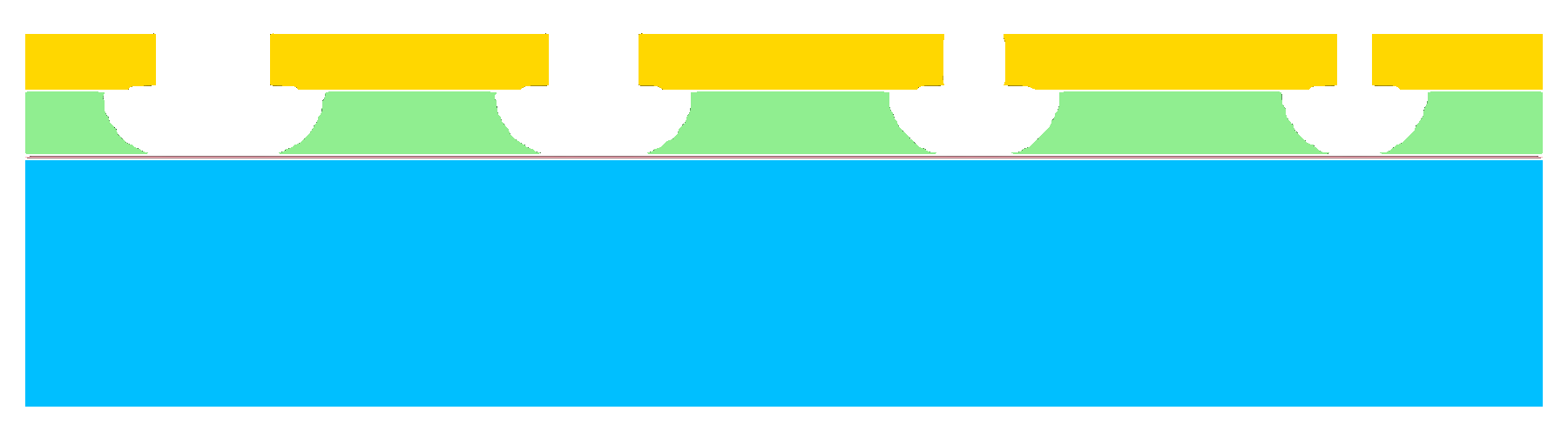

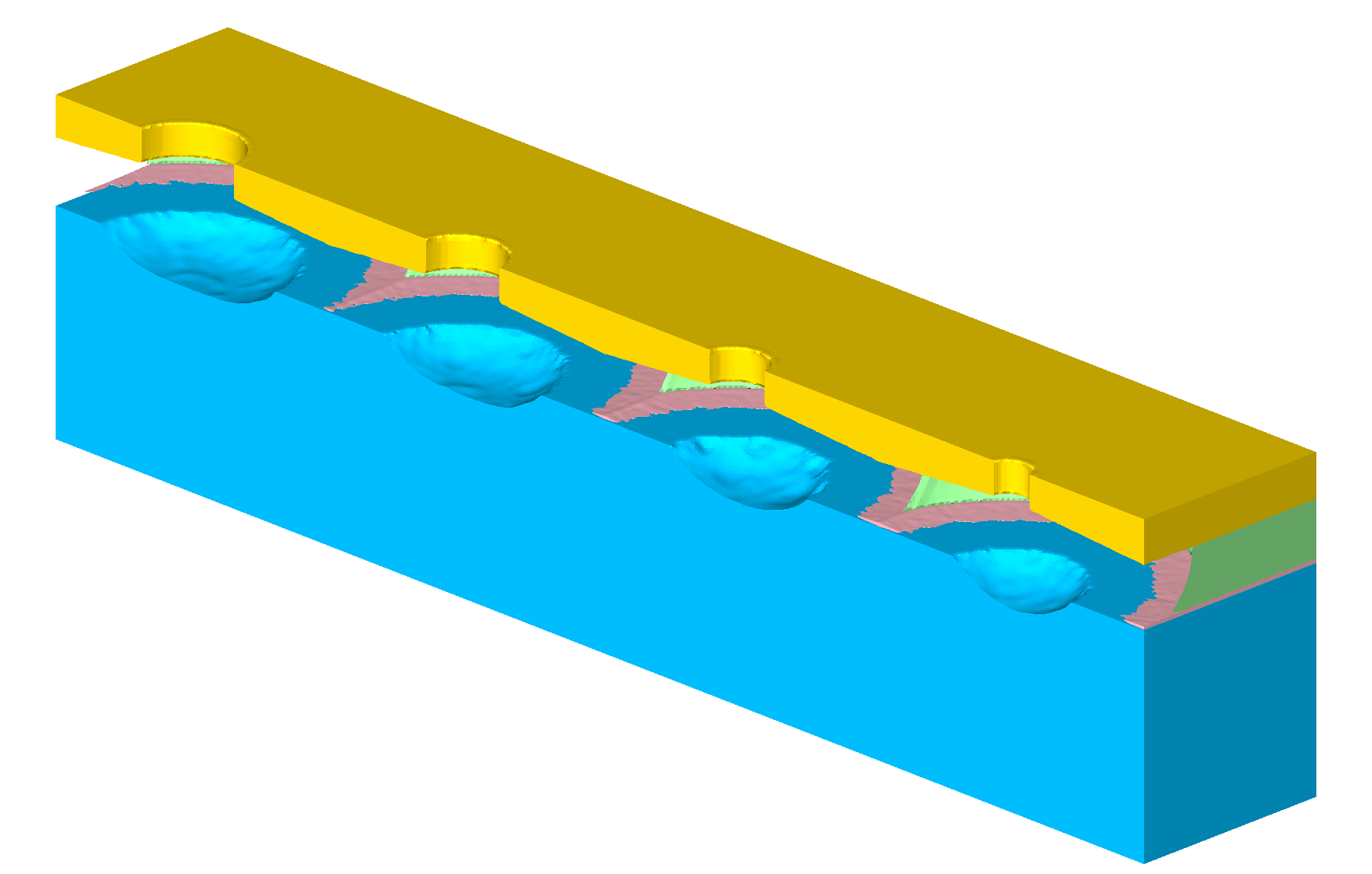

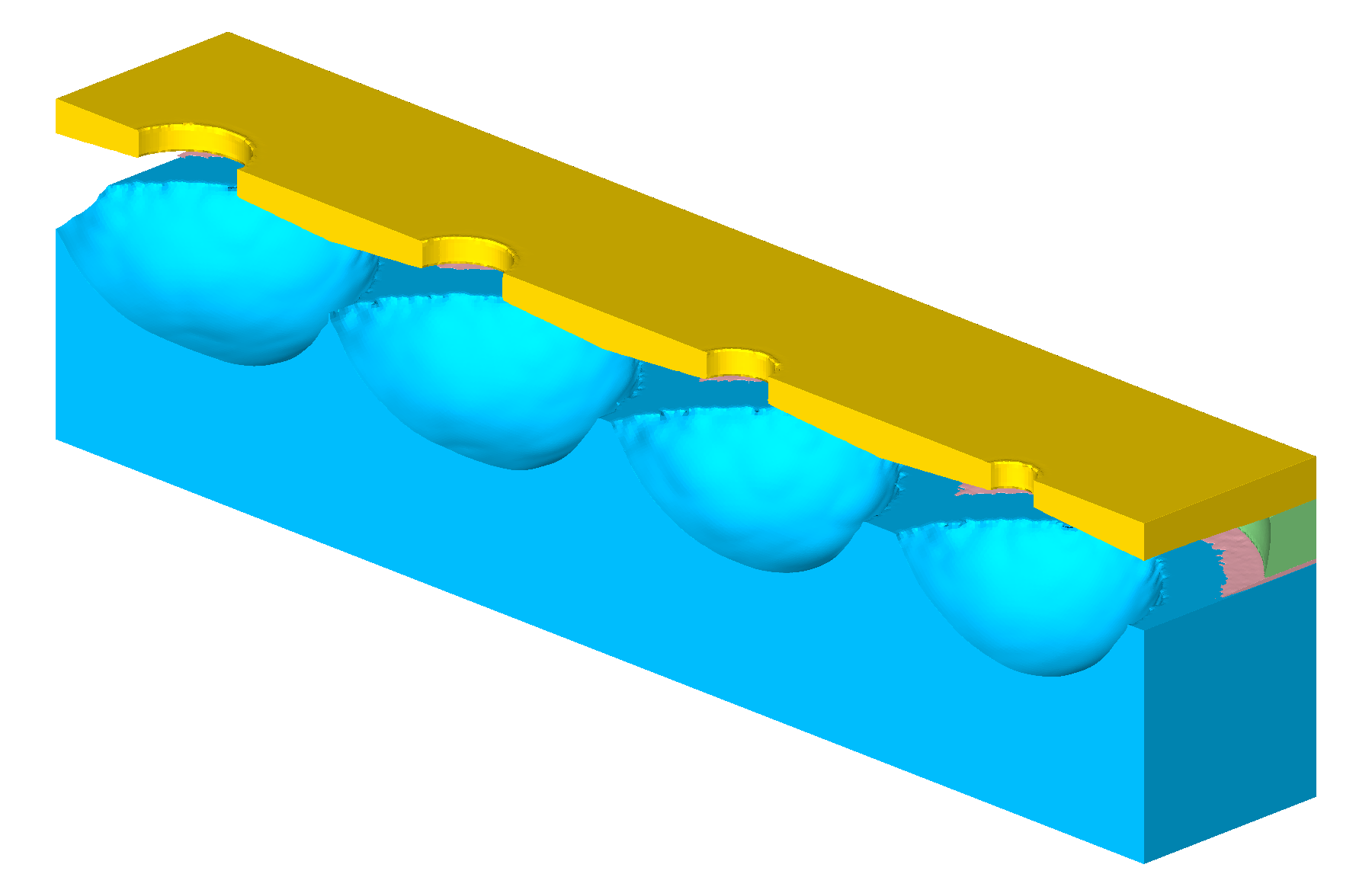

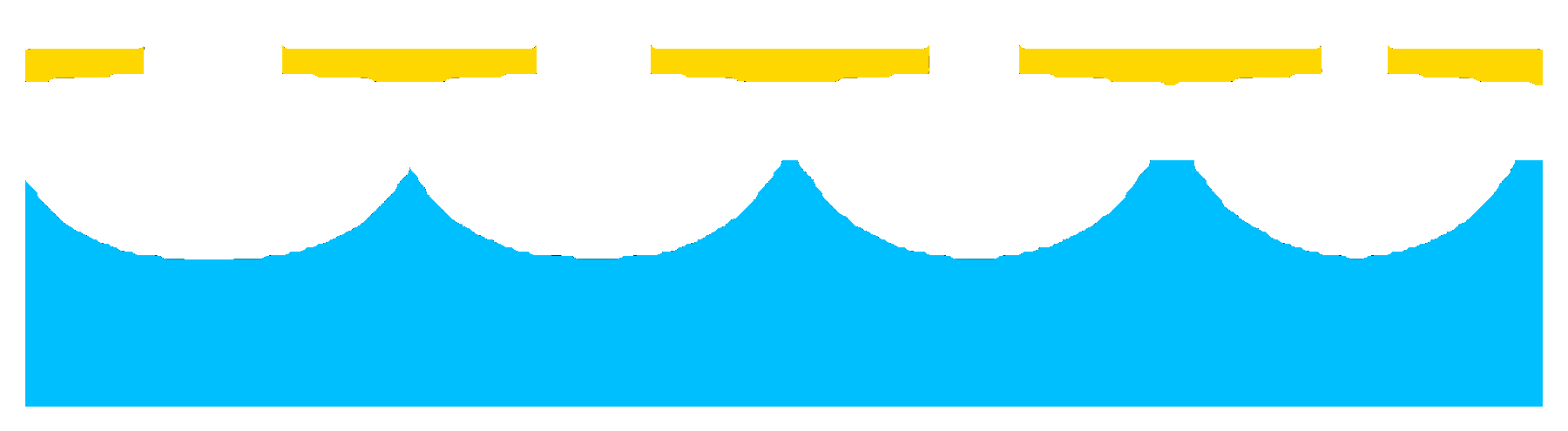

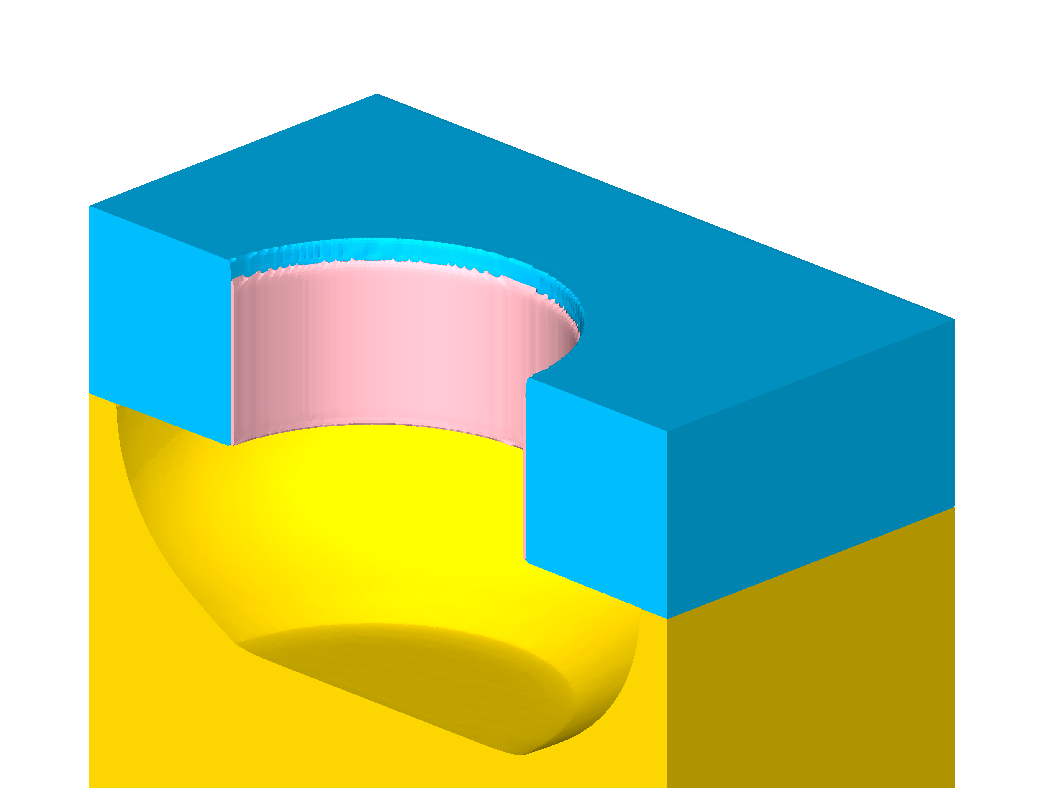

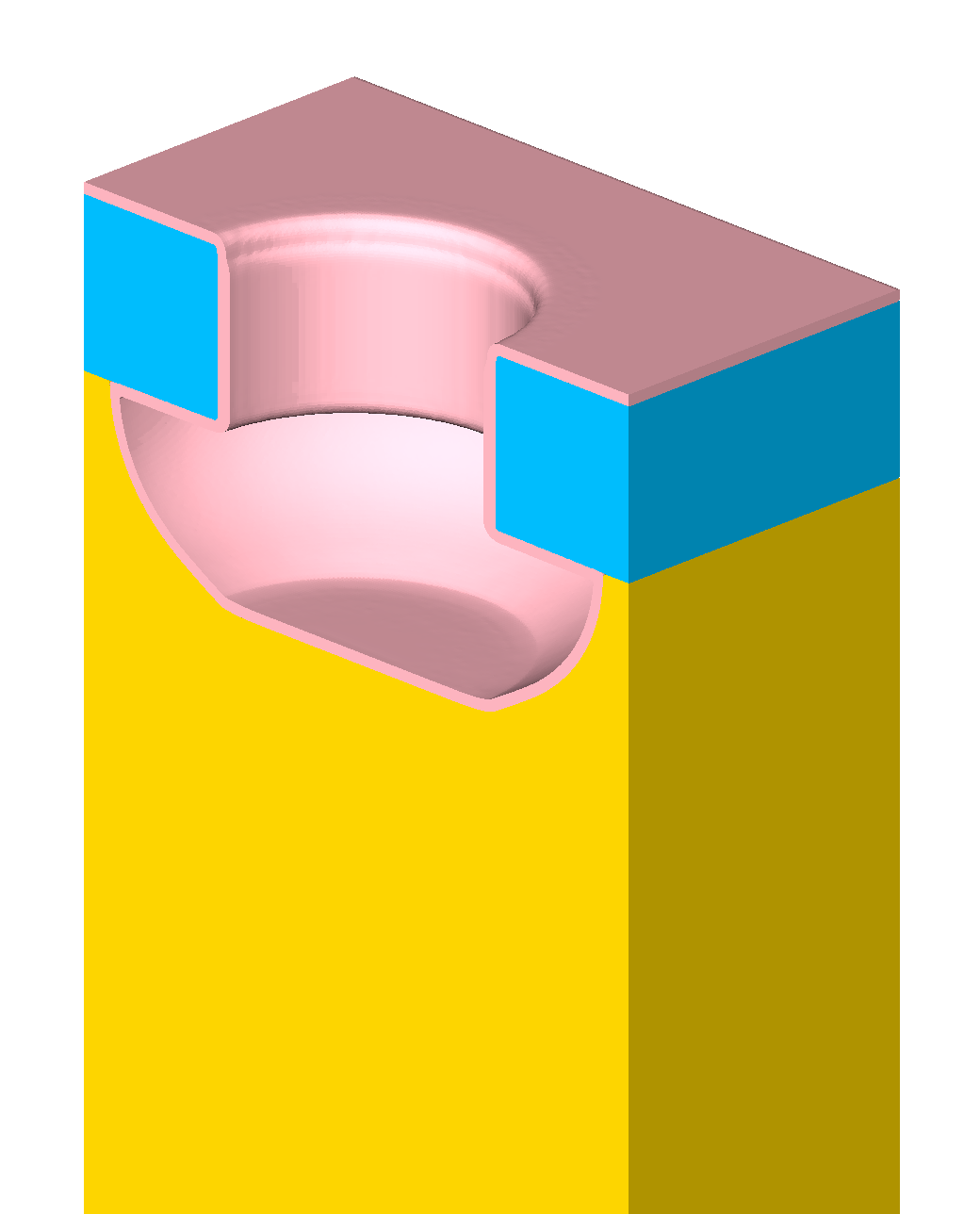

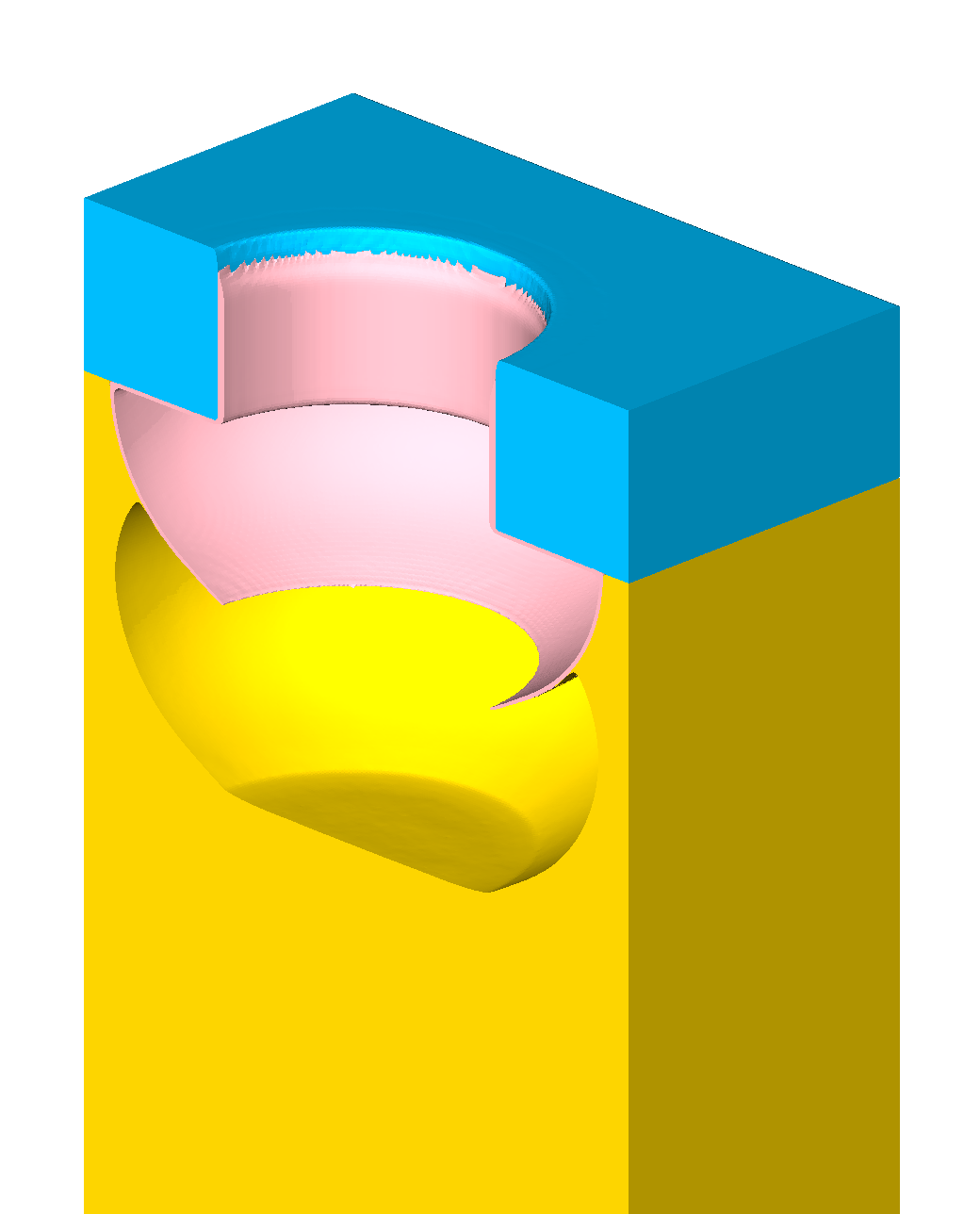

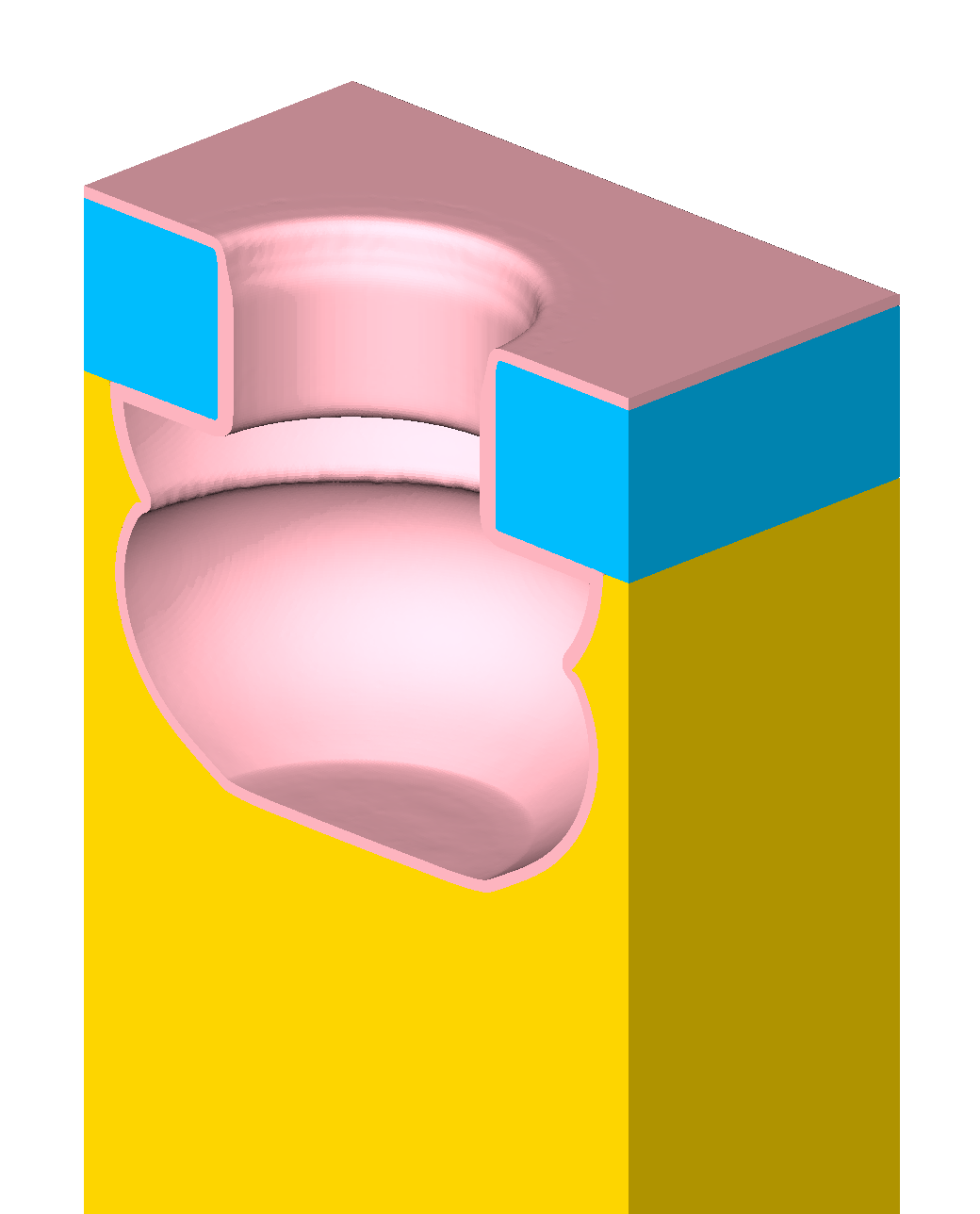

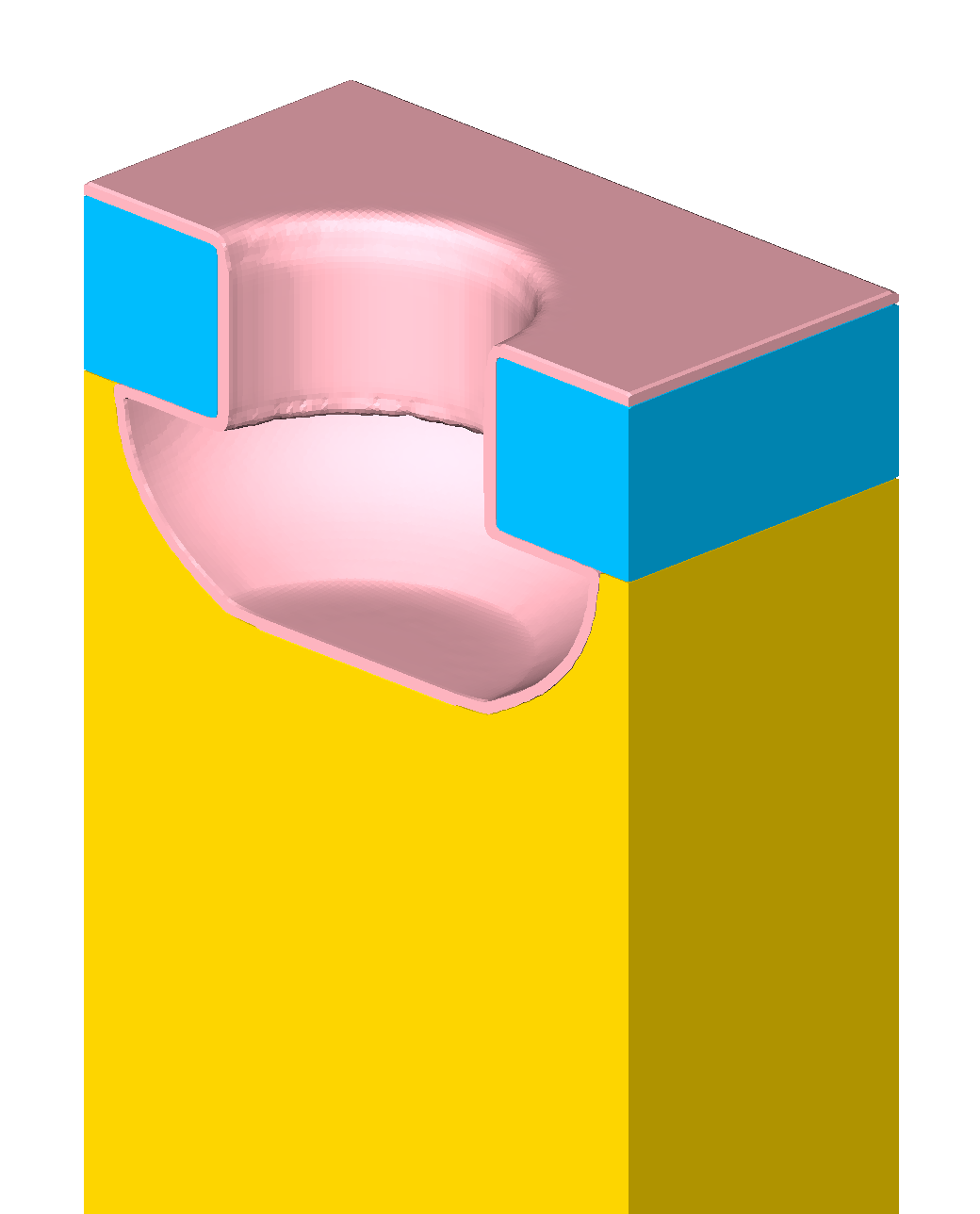

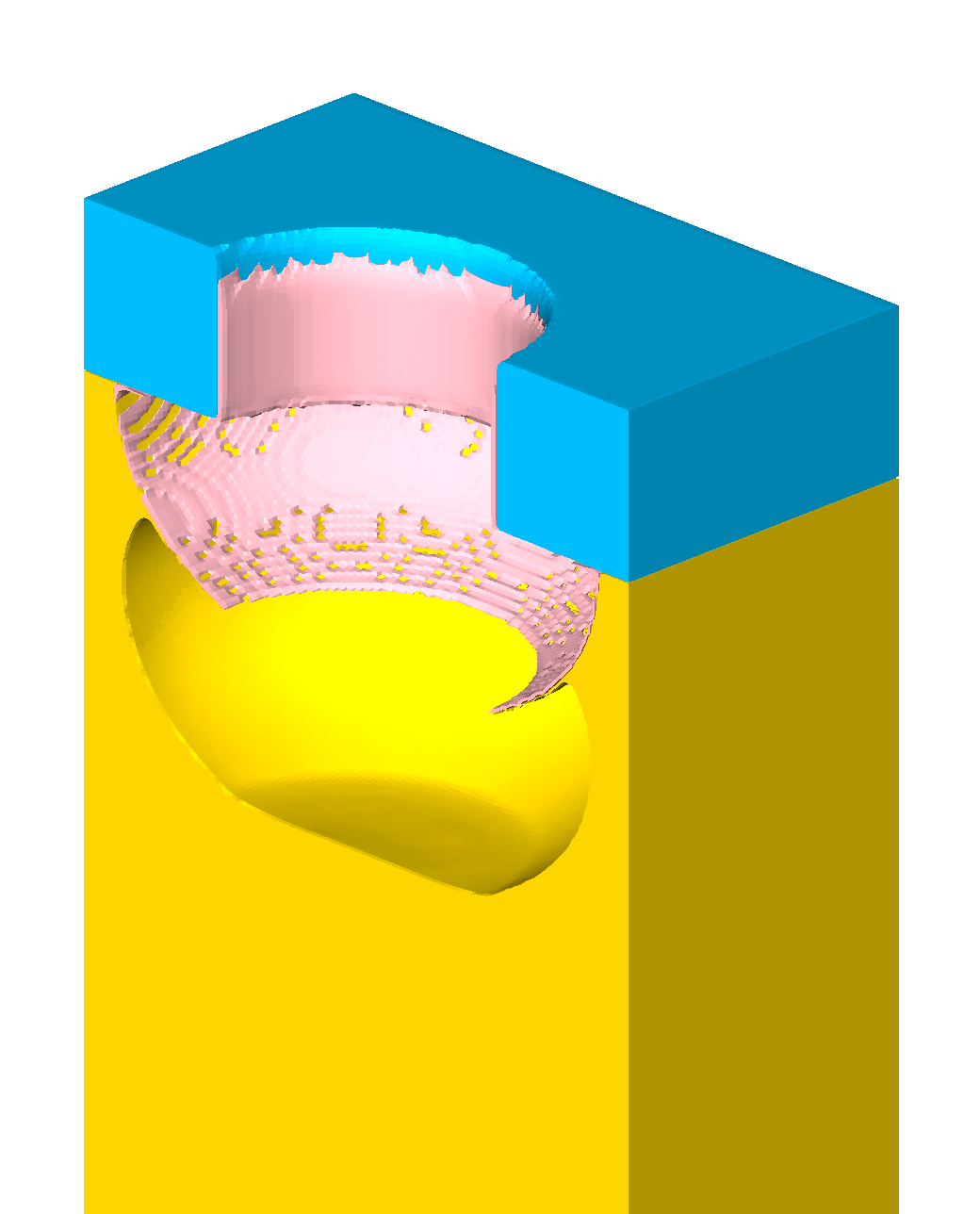

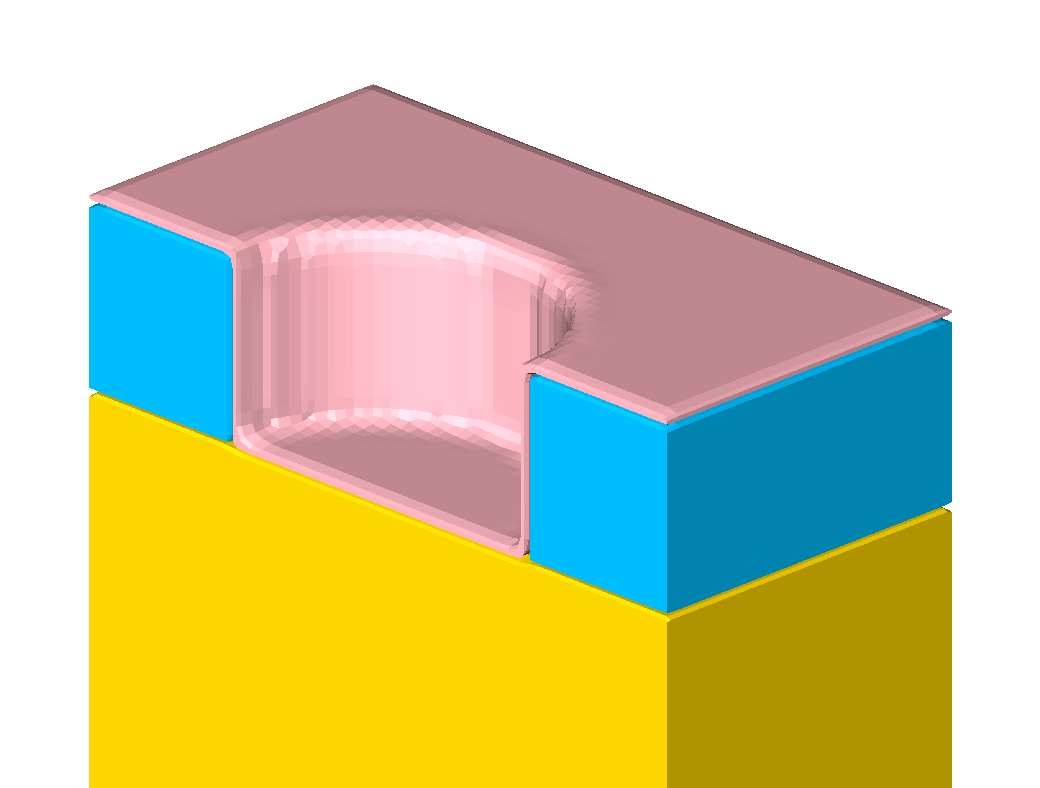

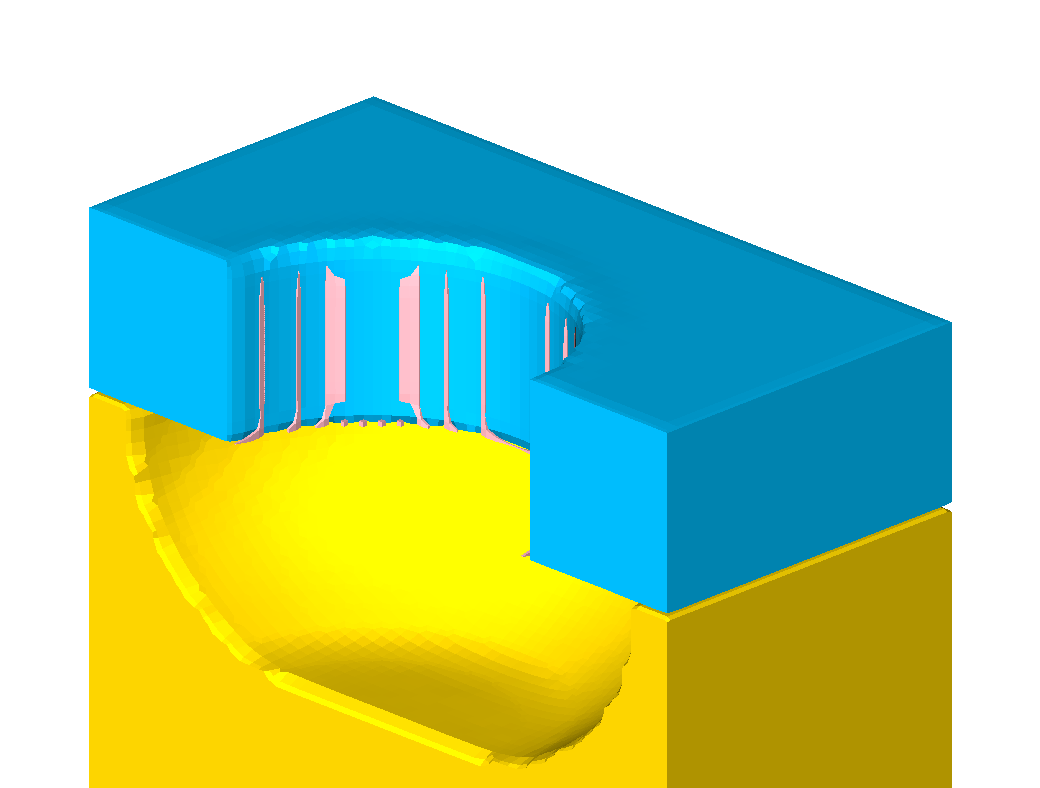

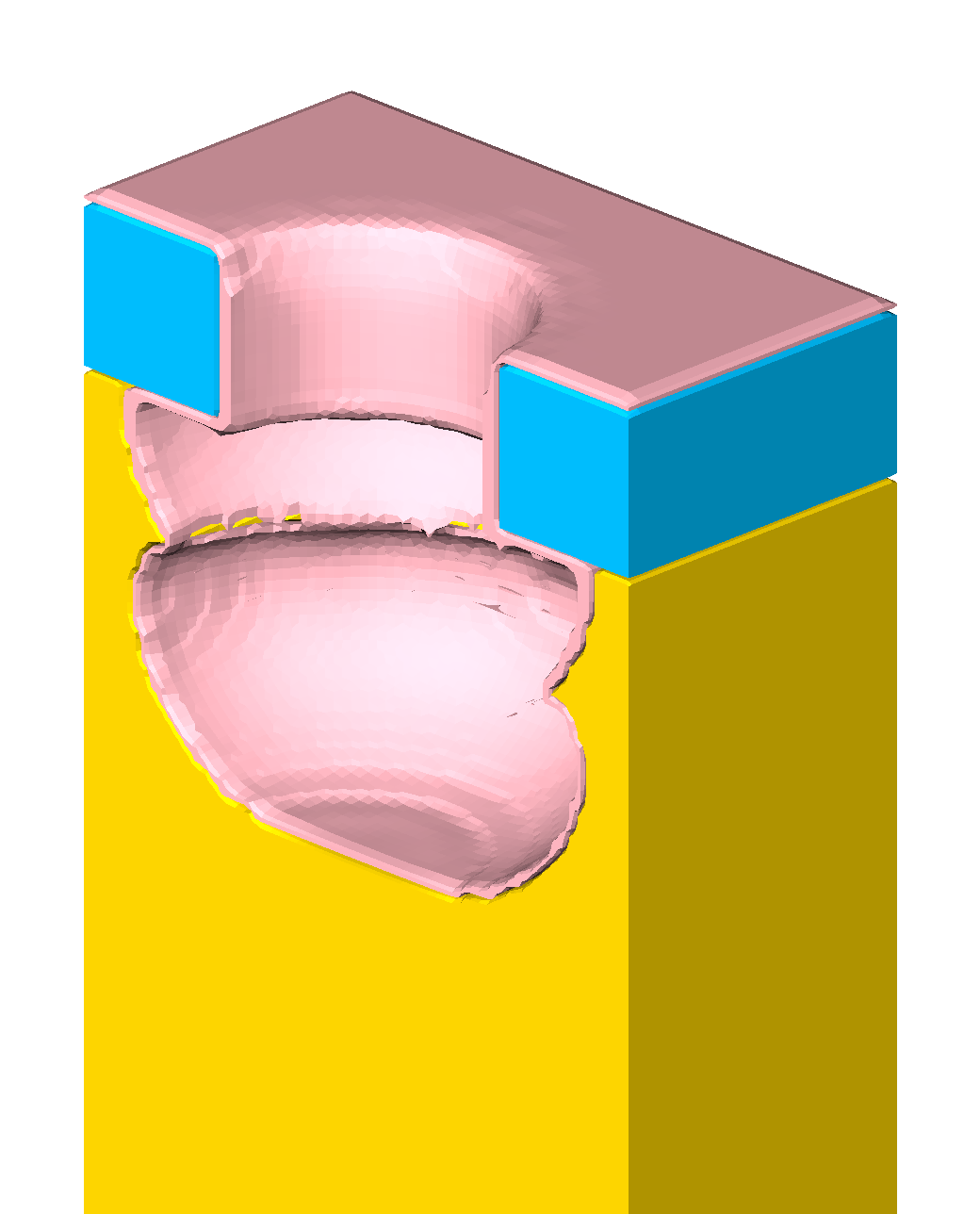

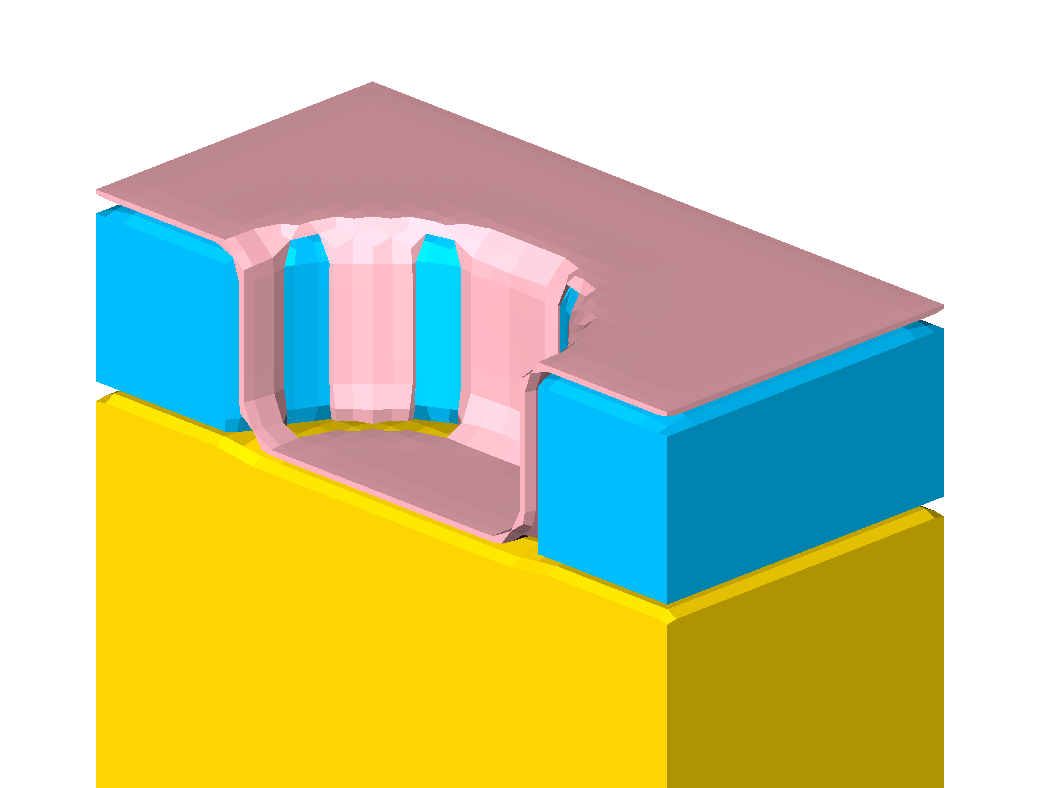

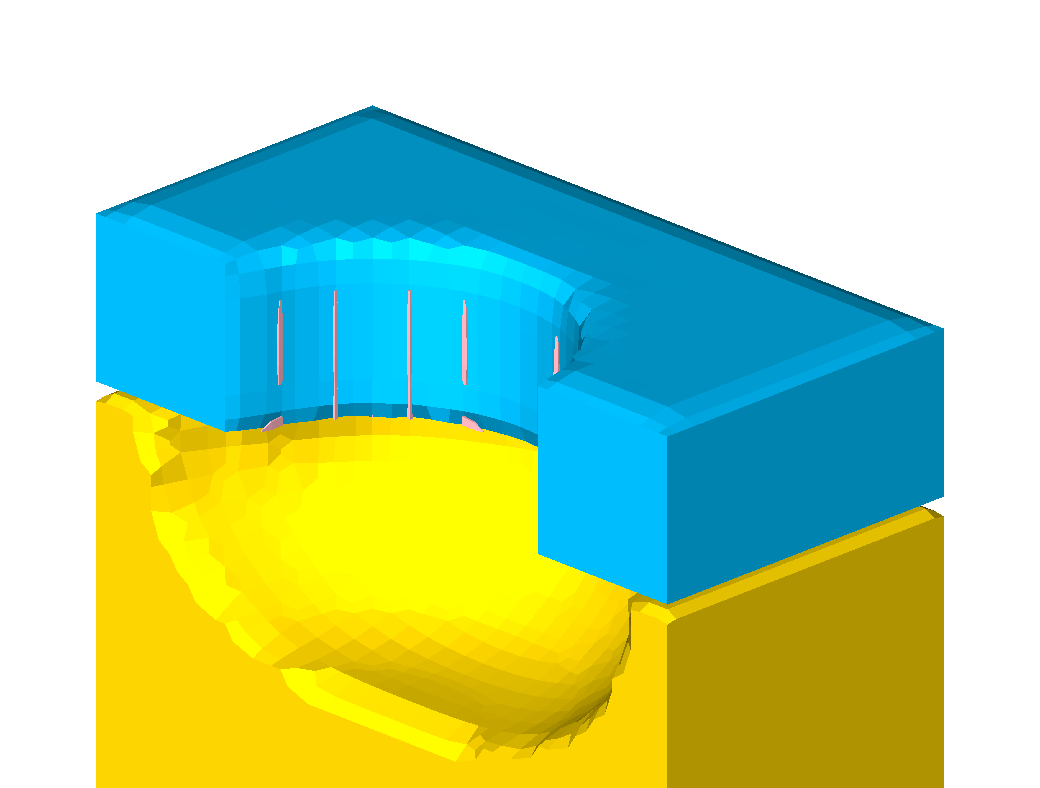

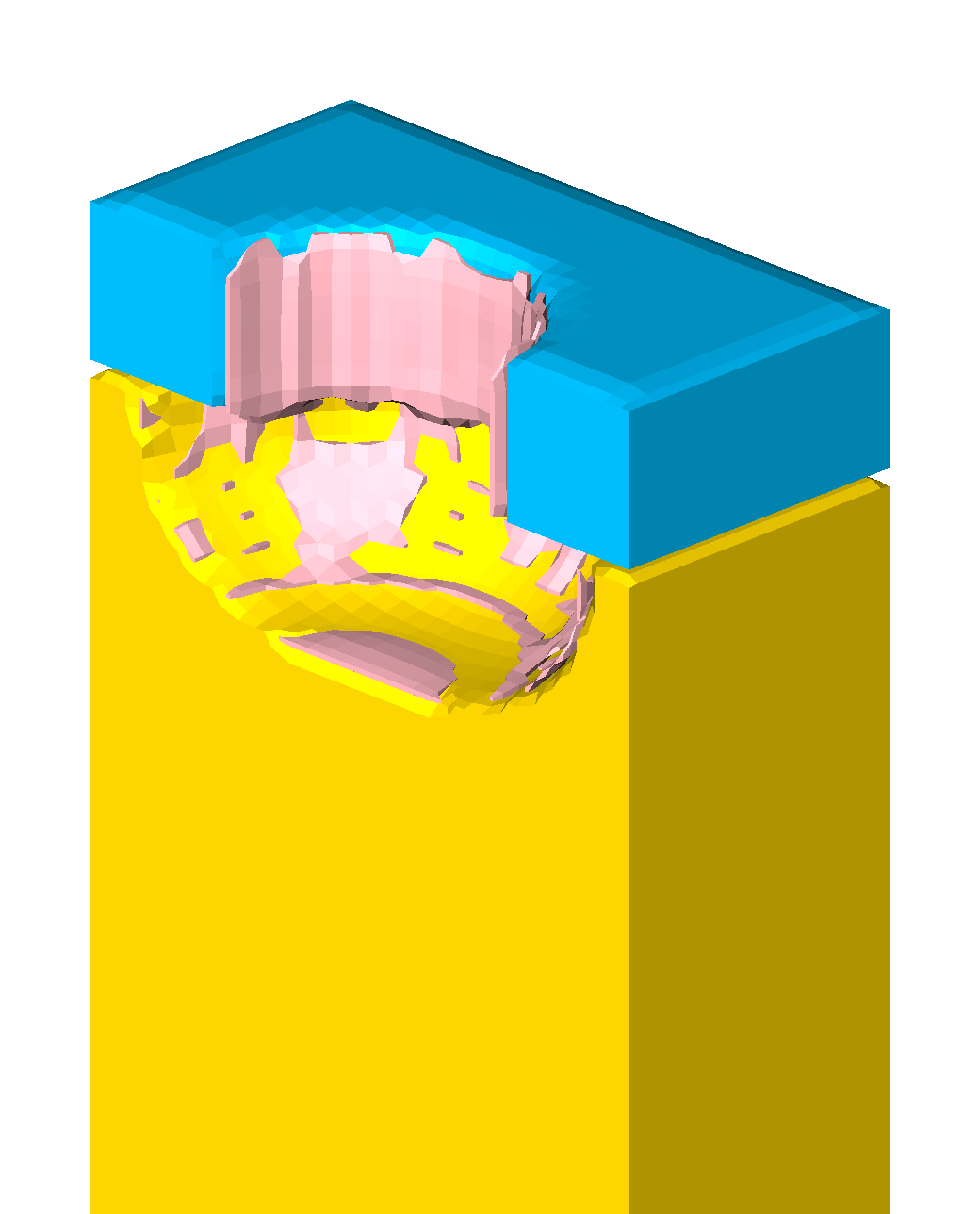

Figure A.5: Extracted material regions for resolution at

, and

. Regions thinner than one grid cell potentially vanish during the Boolean operations between the level-sets,

which is visible in (c) and (d) near the edge of the crater in the blue material. The same results for

resolutions

and

are provided in Figures A.6

and A.7.

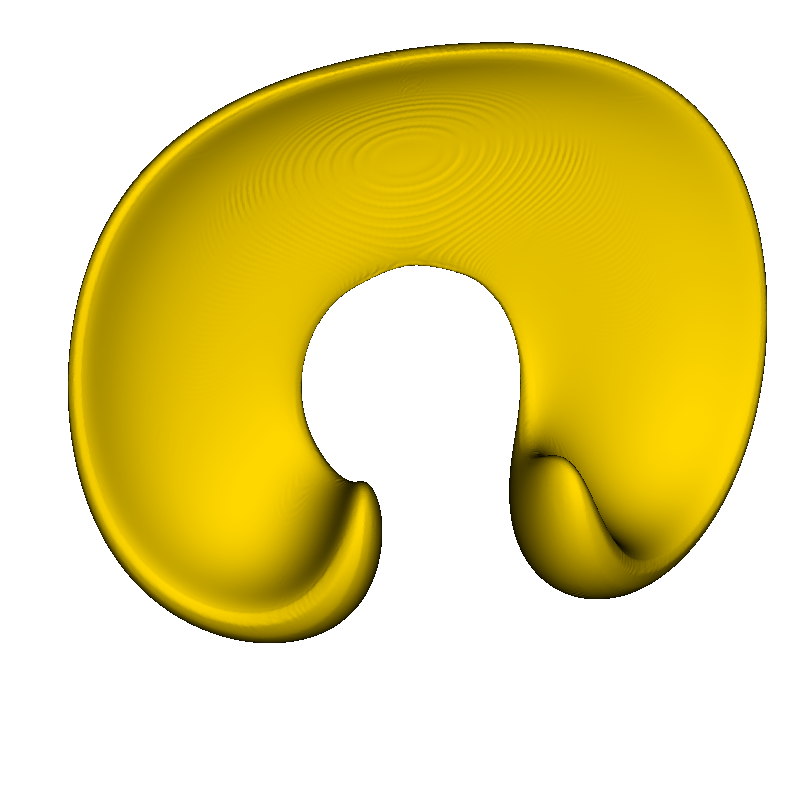

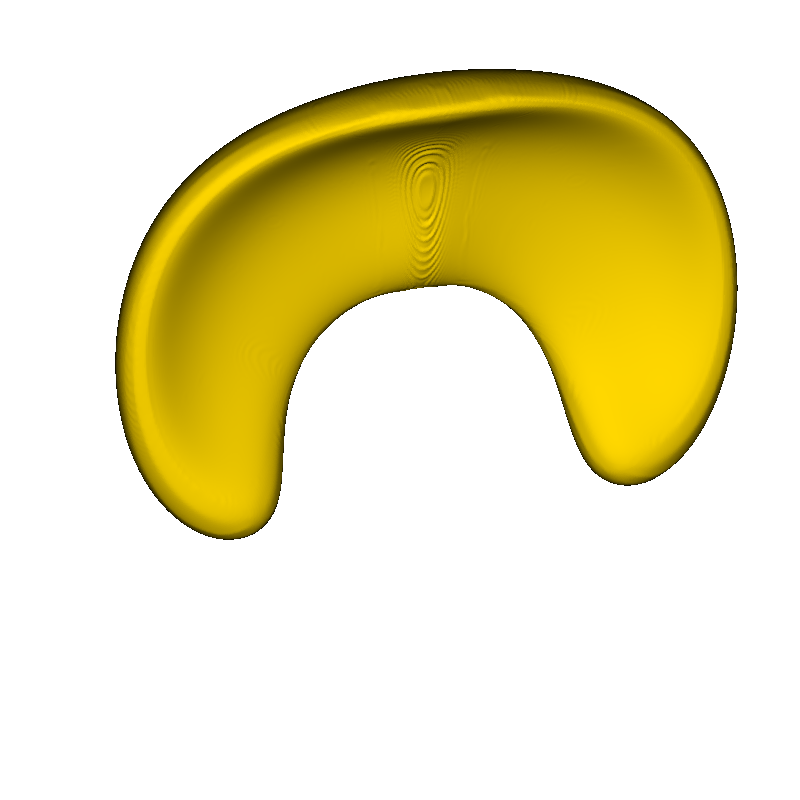

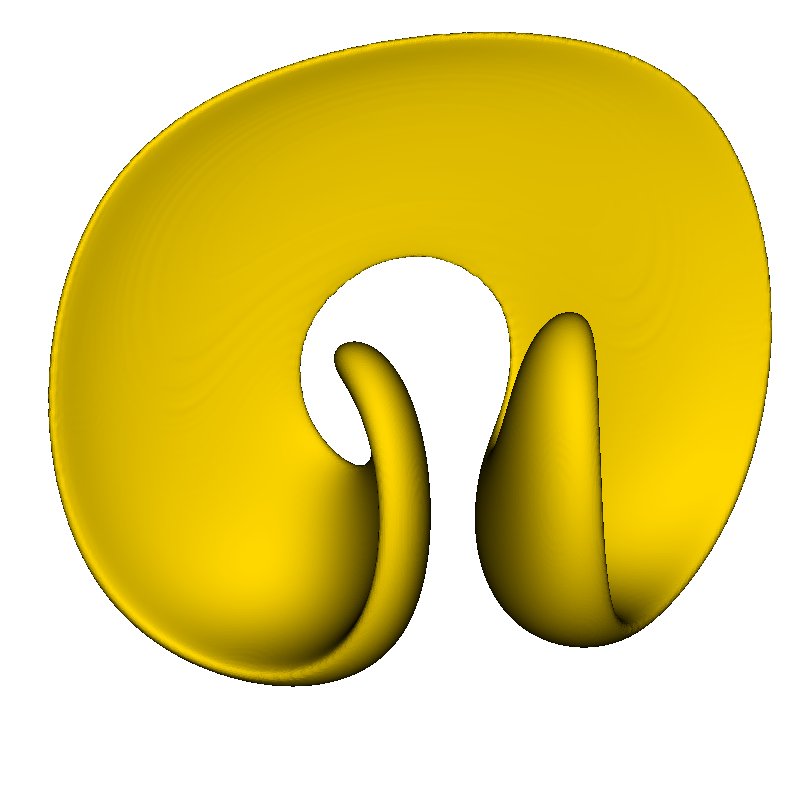

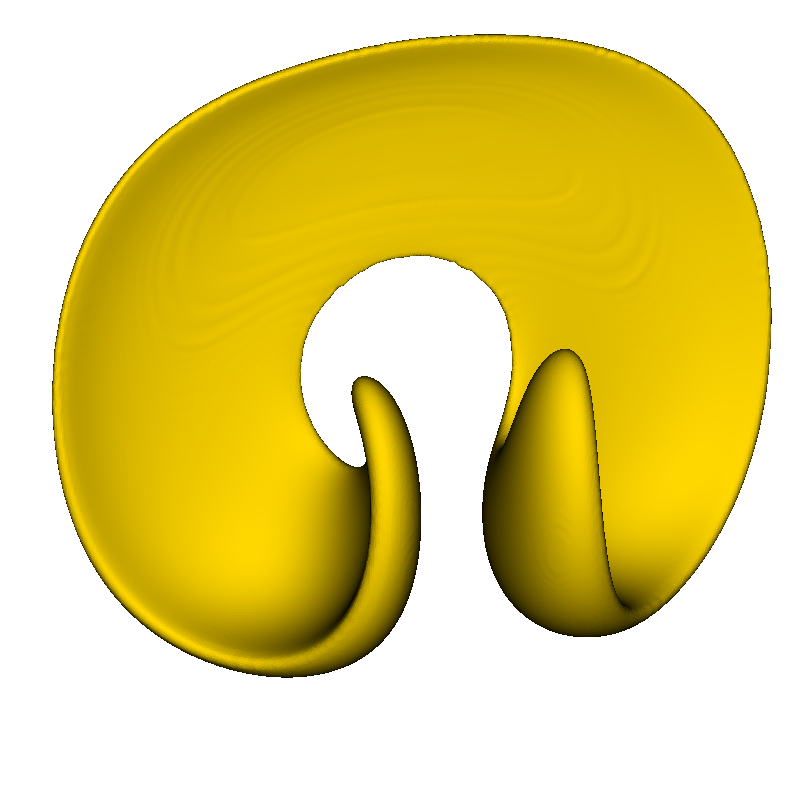

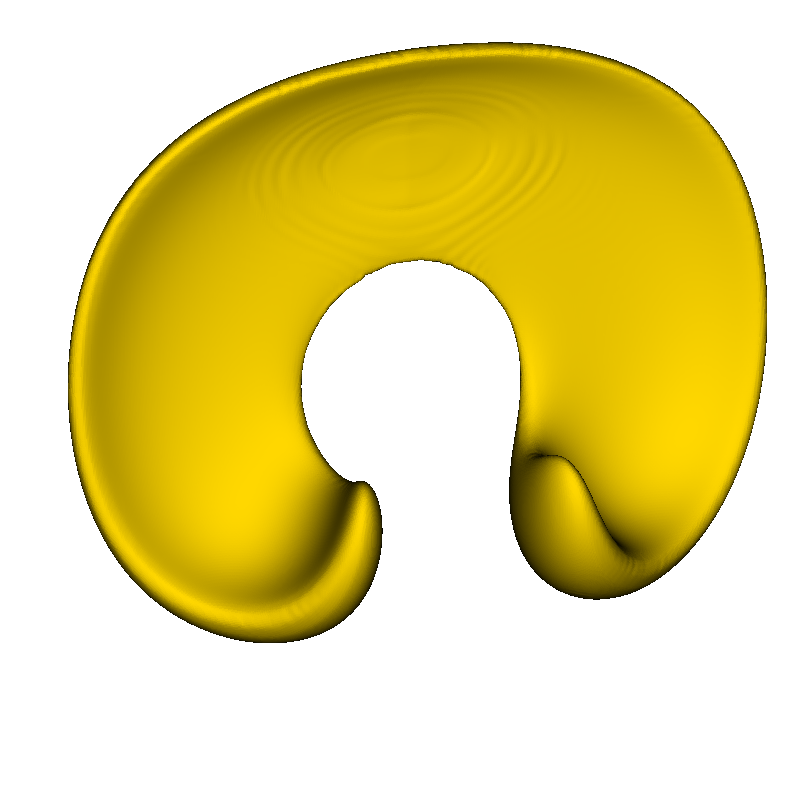

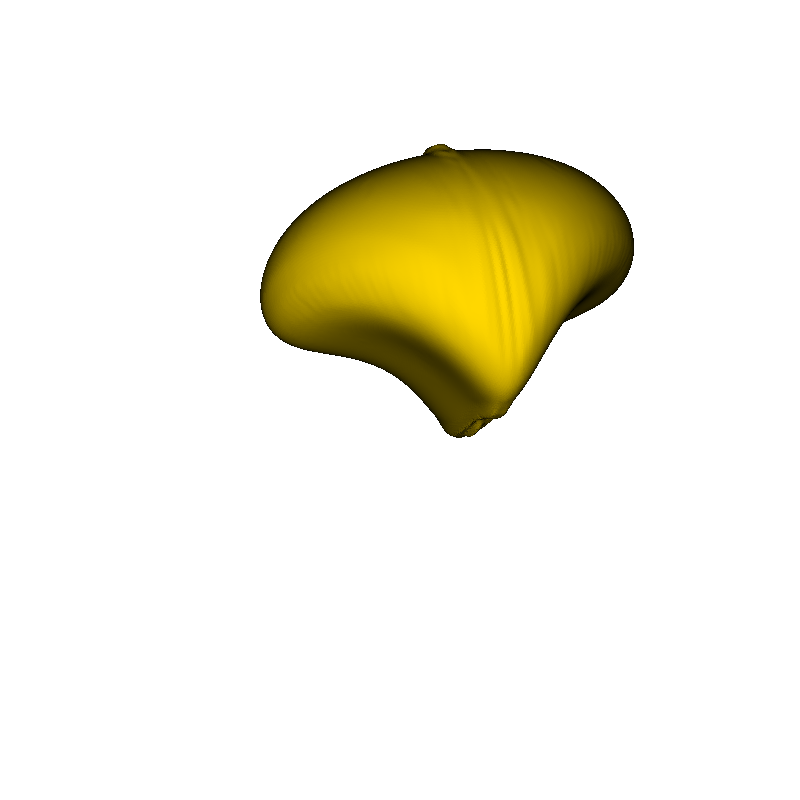

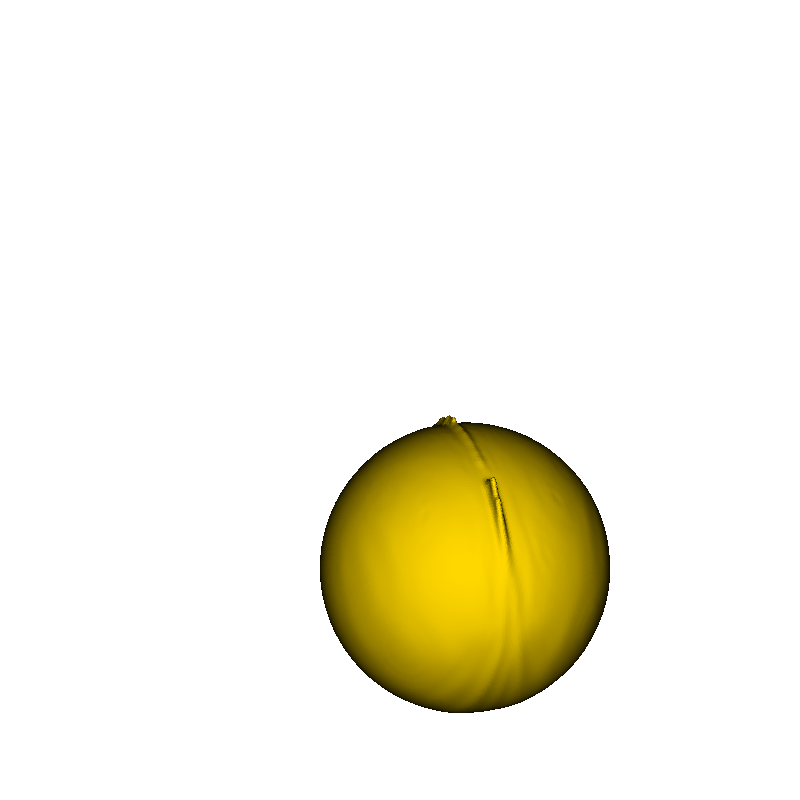

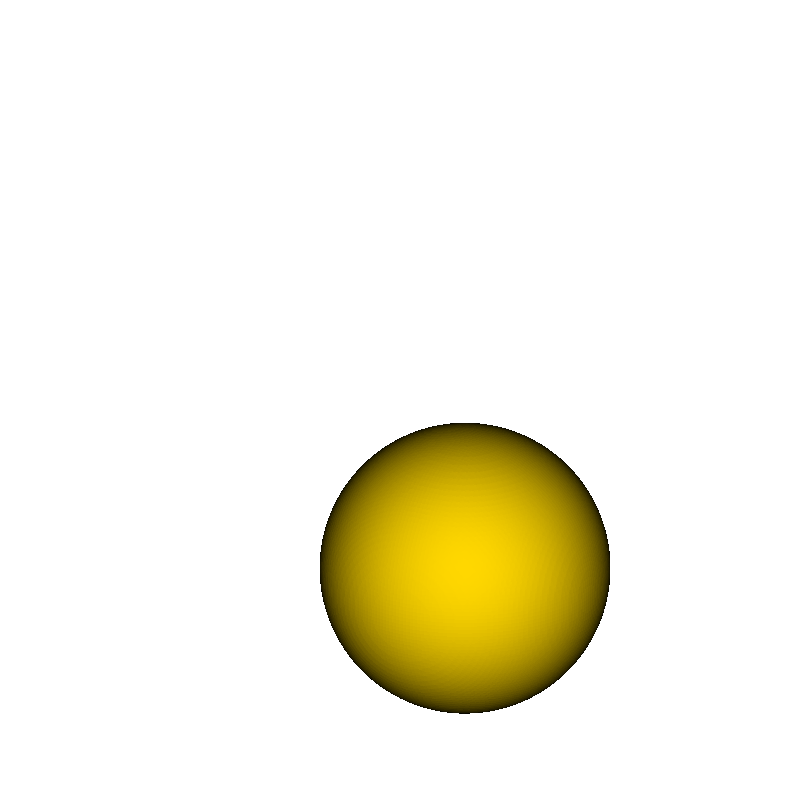

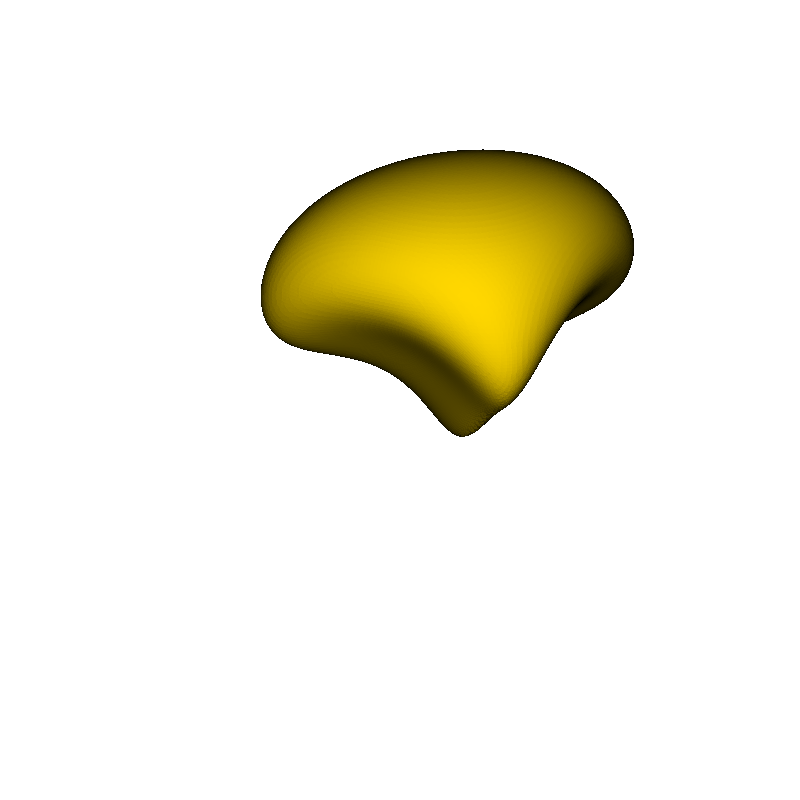

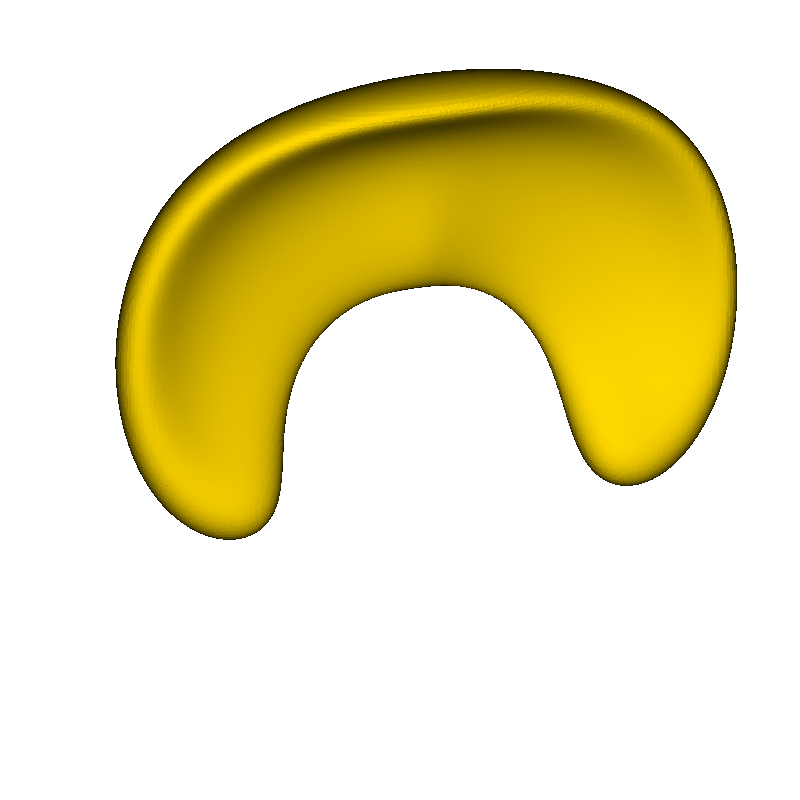

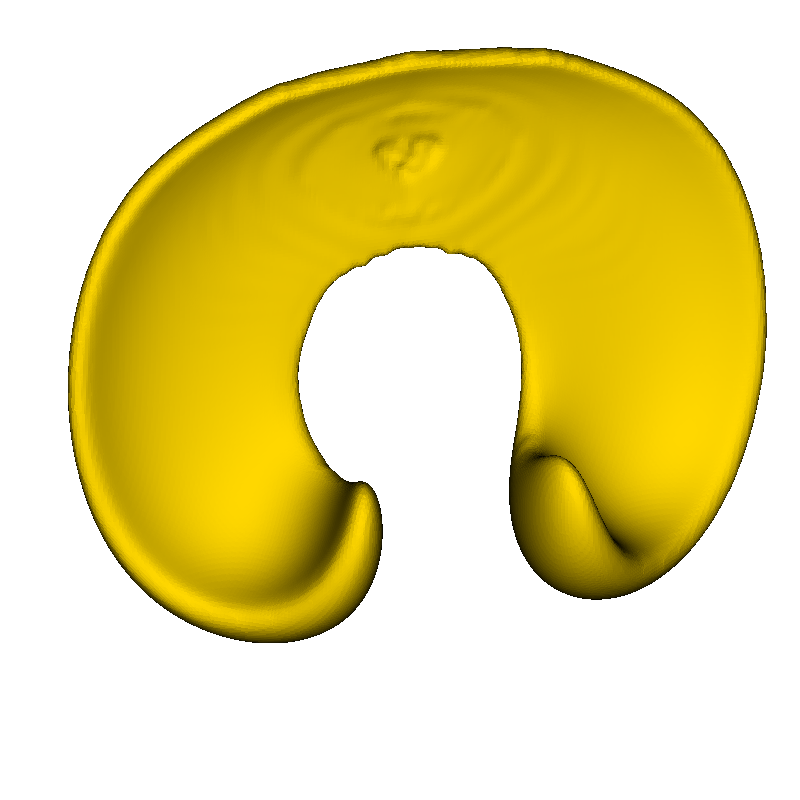

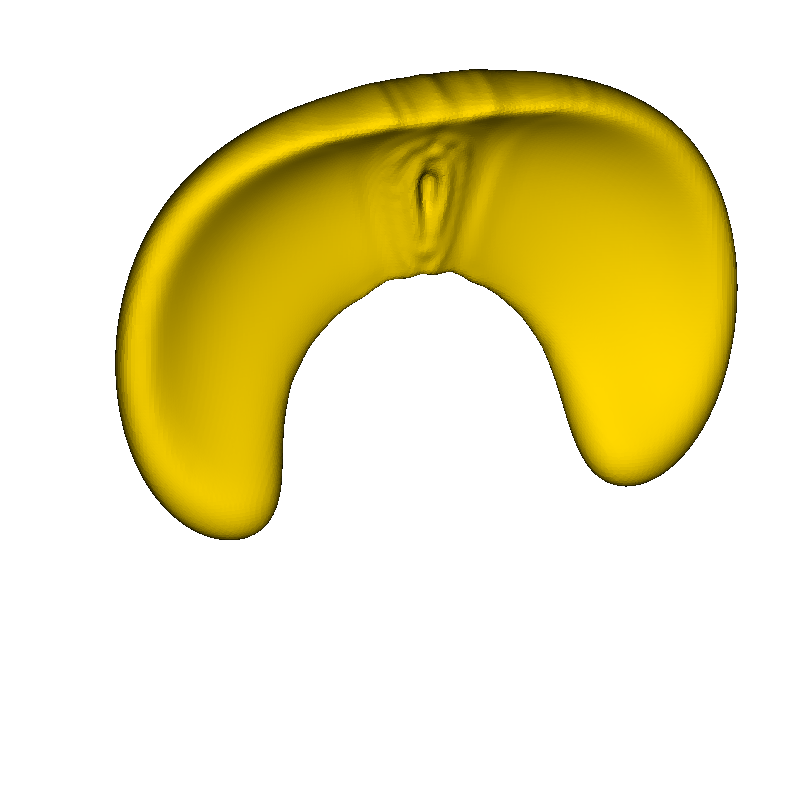

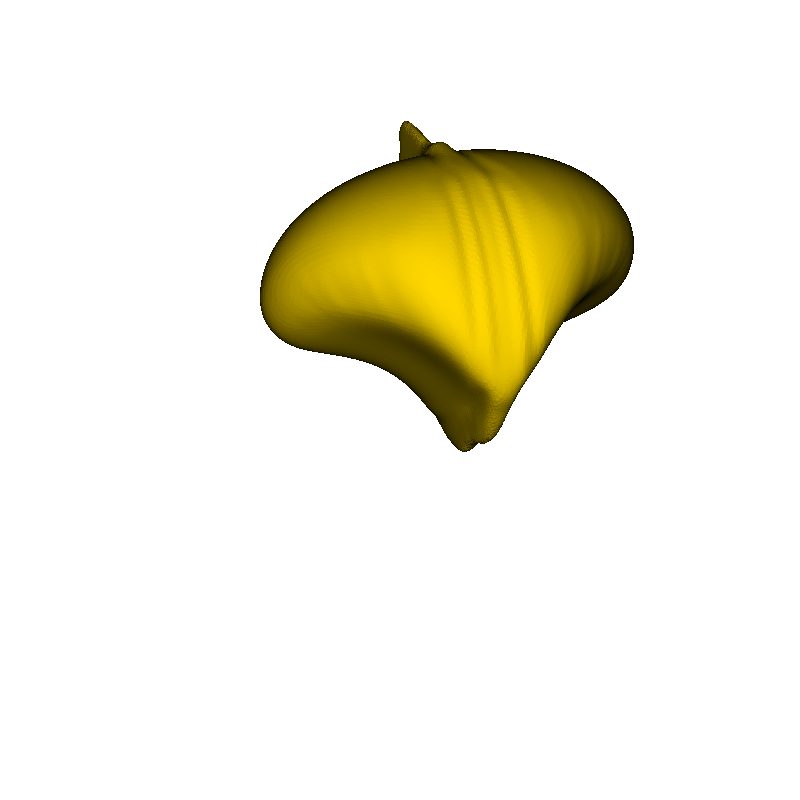

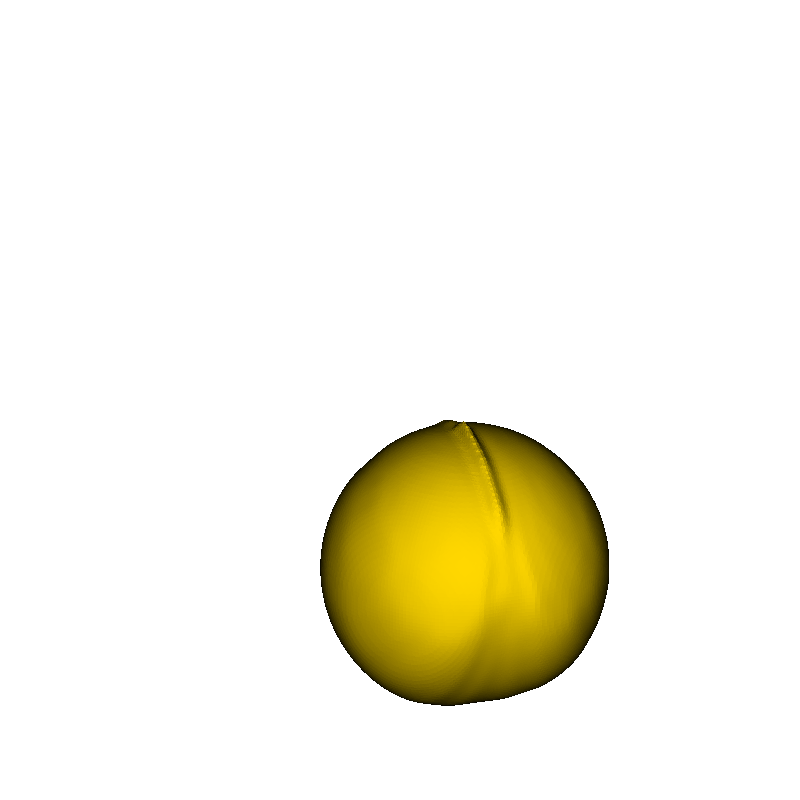

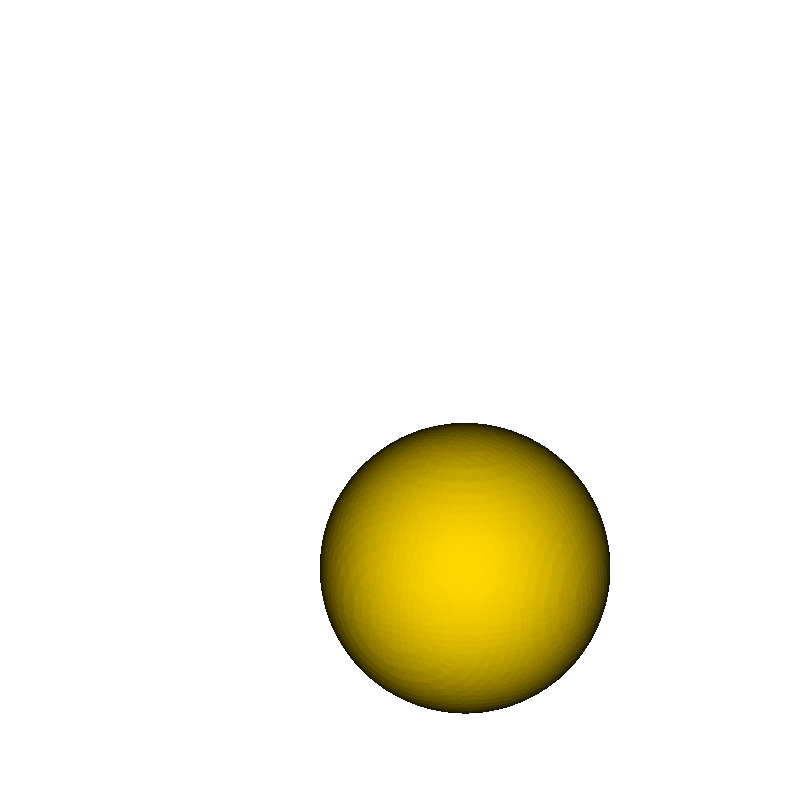

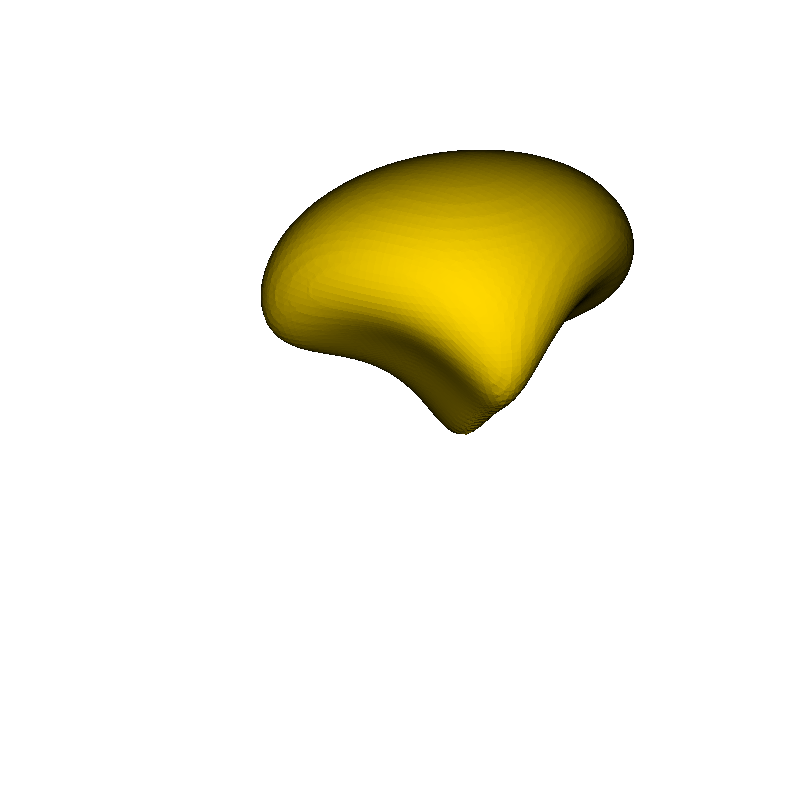

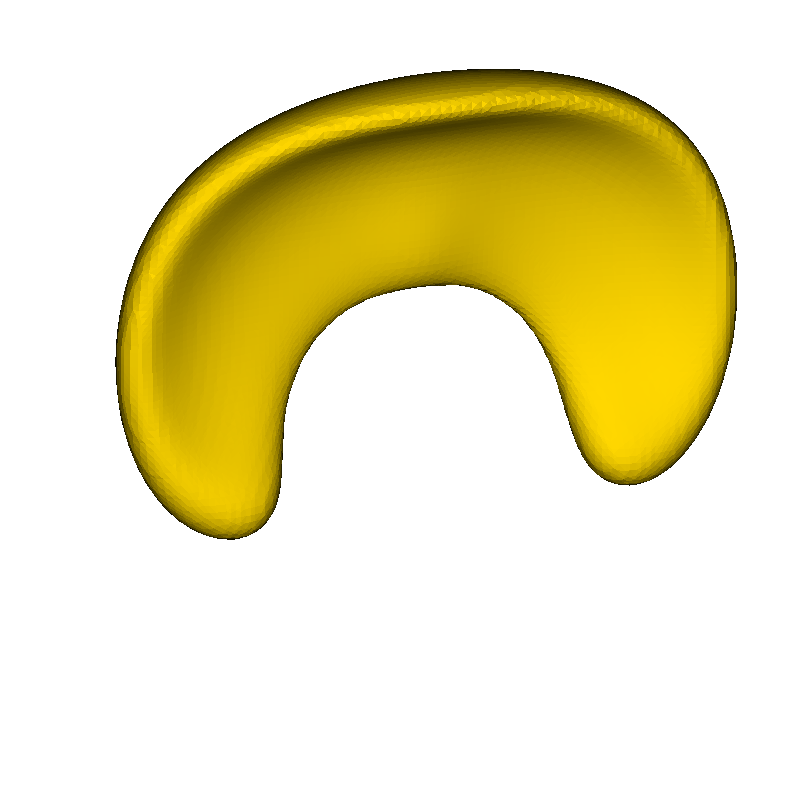

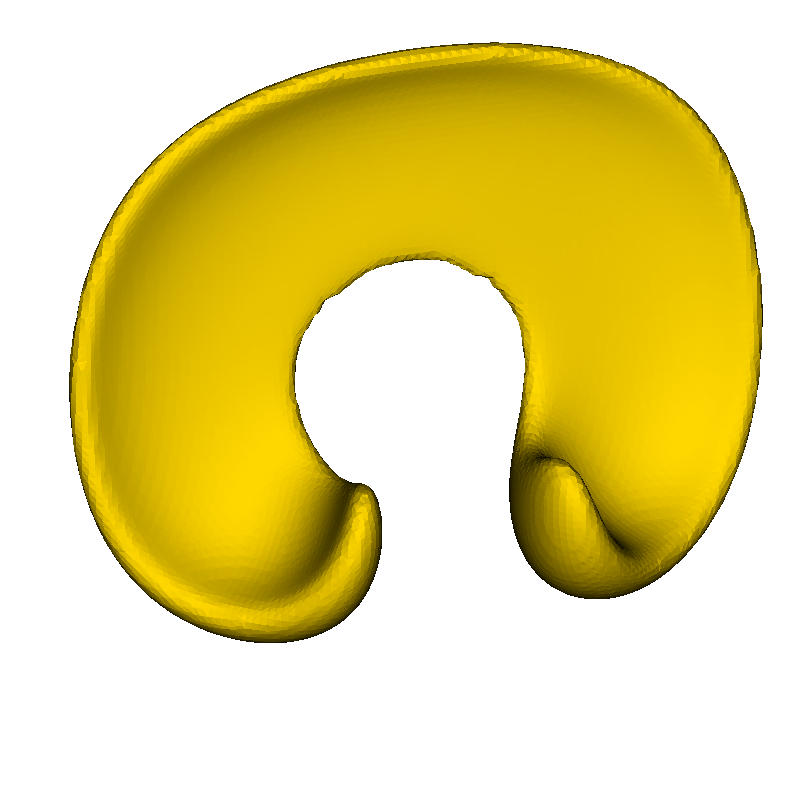

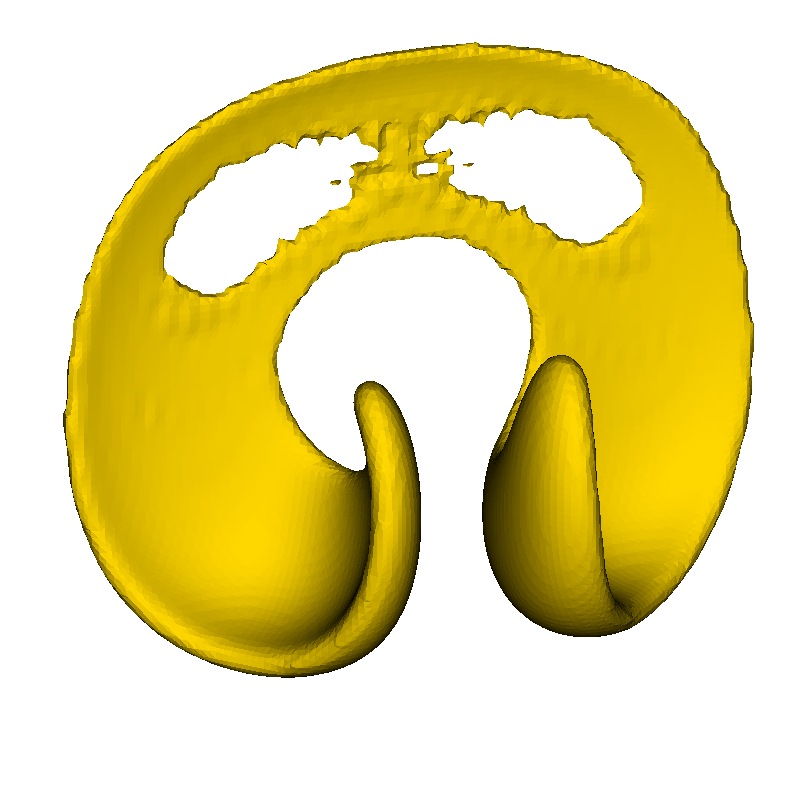

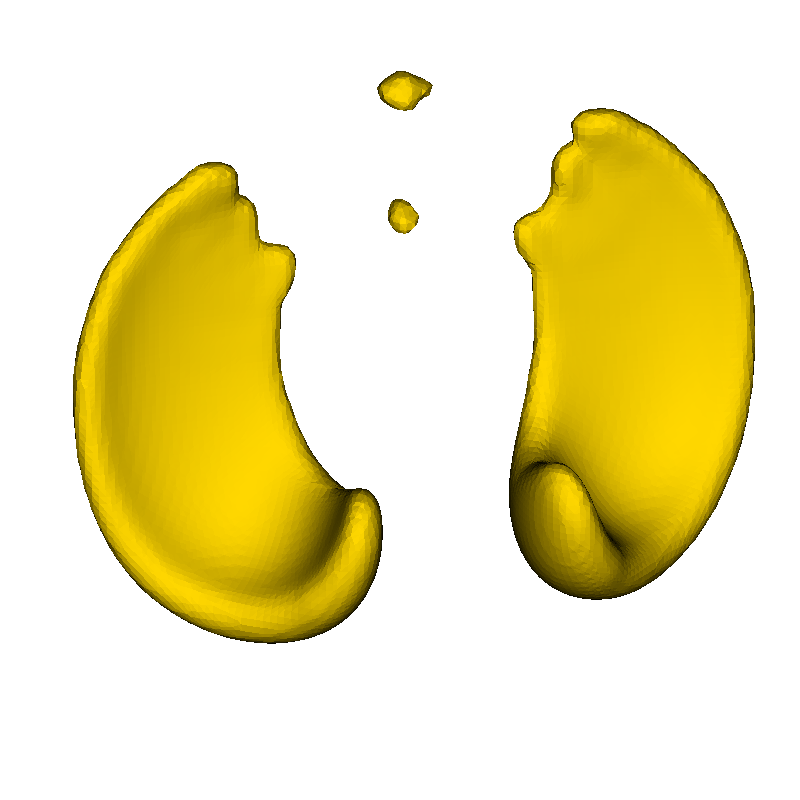

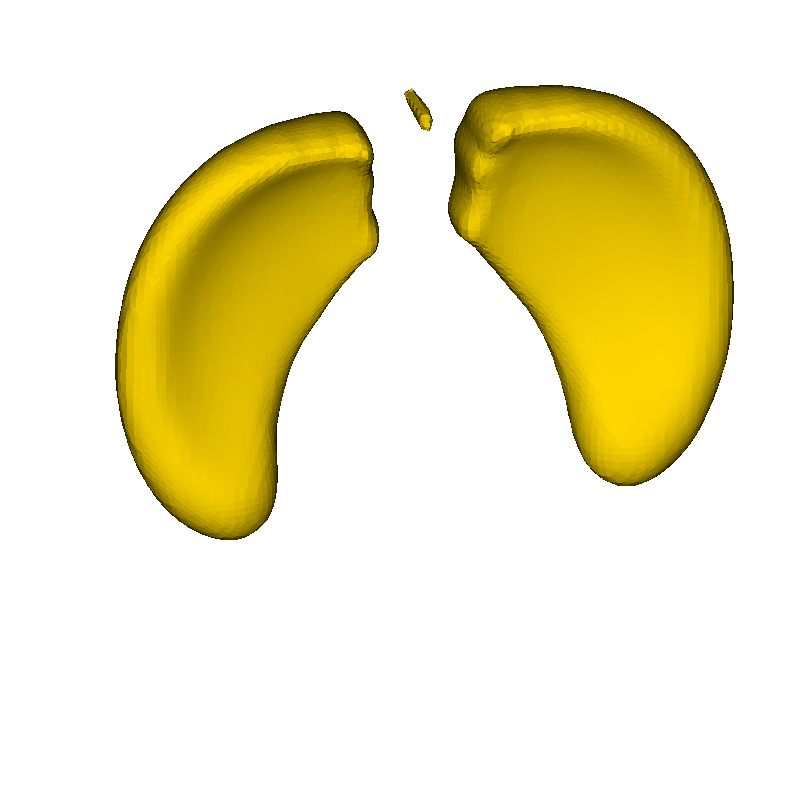

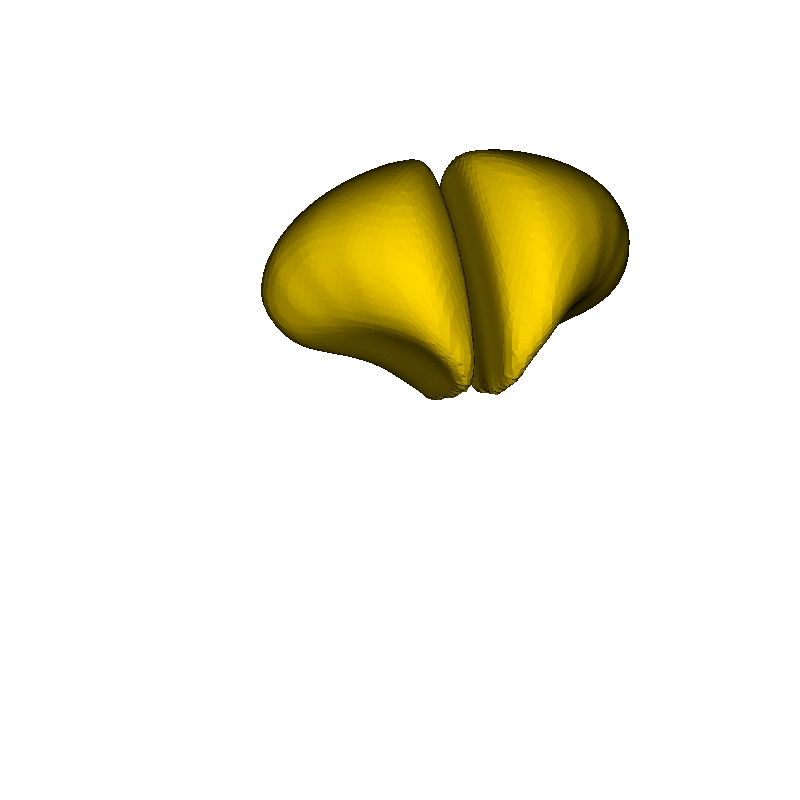

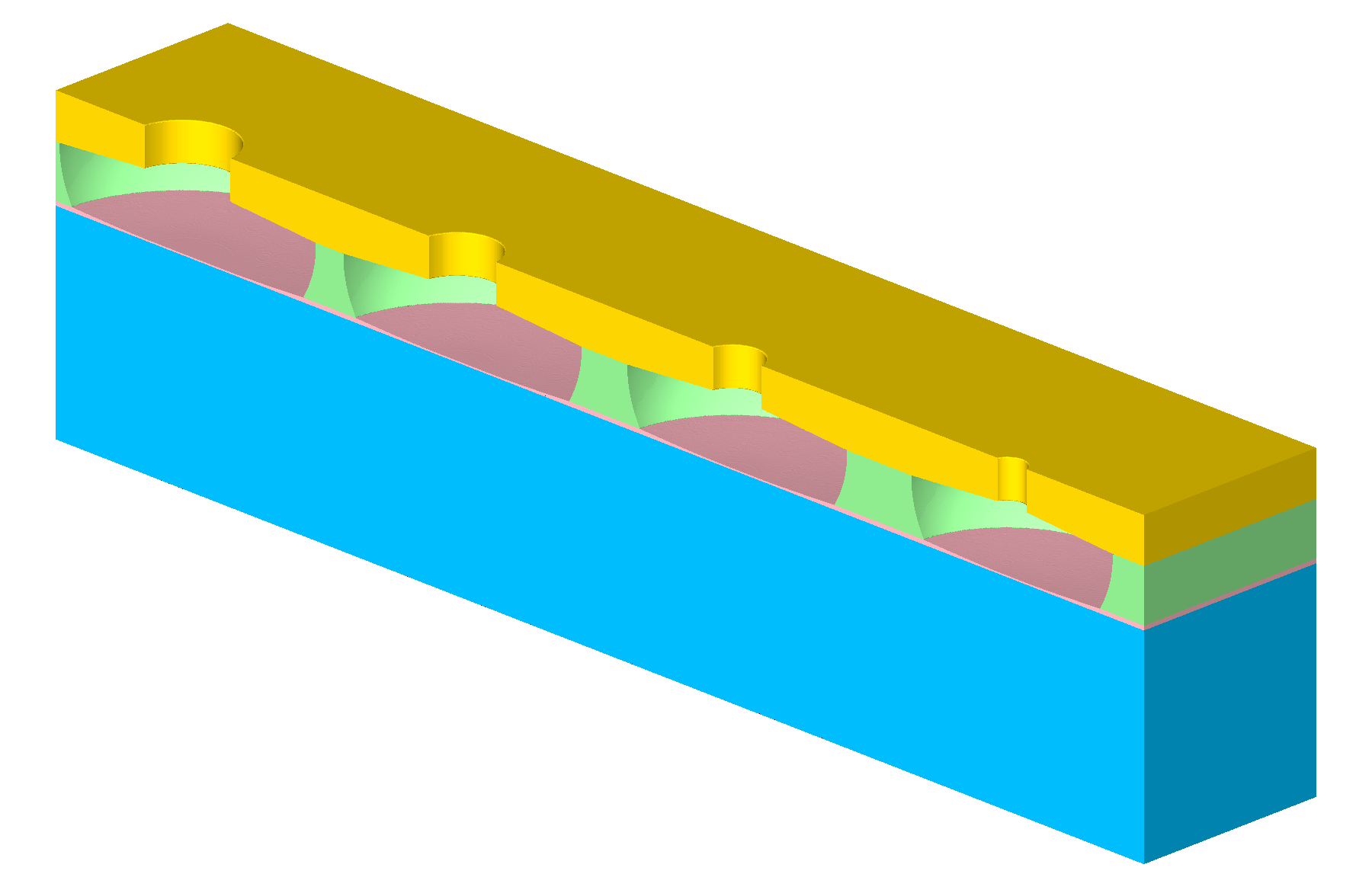

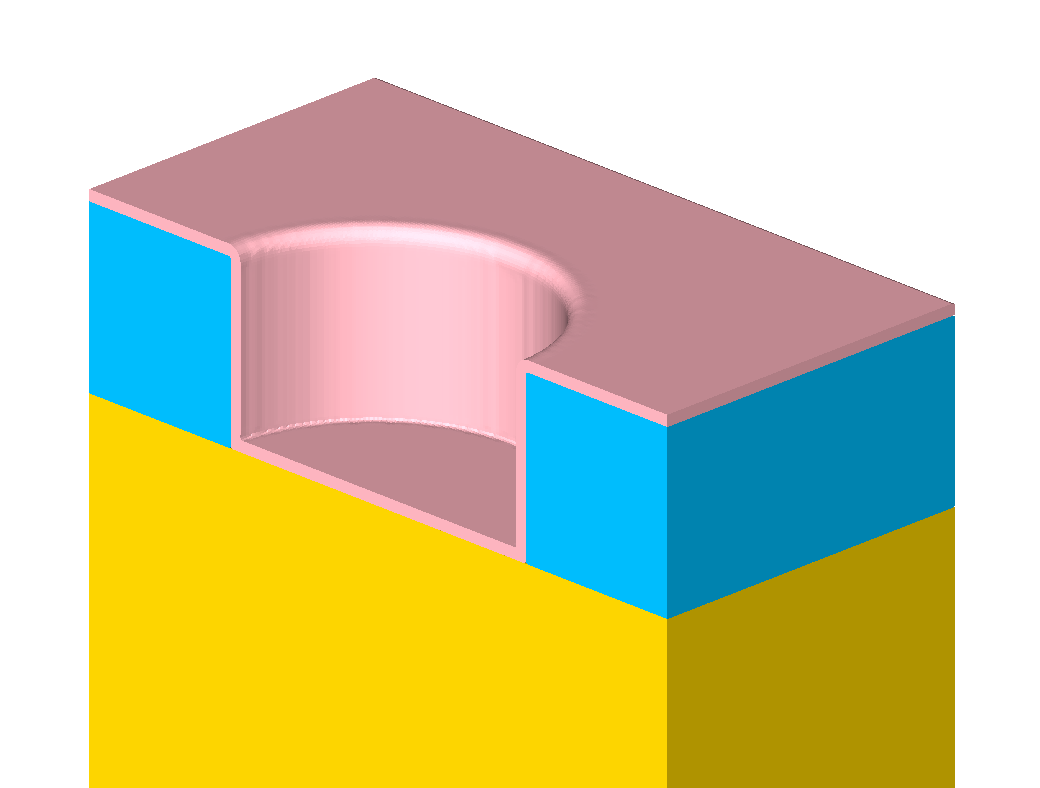

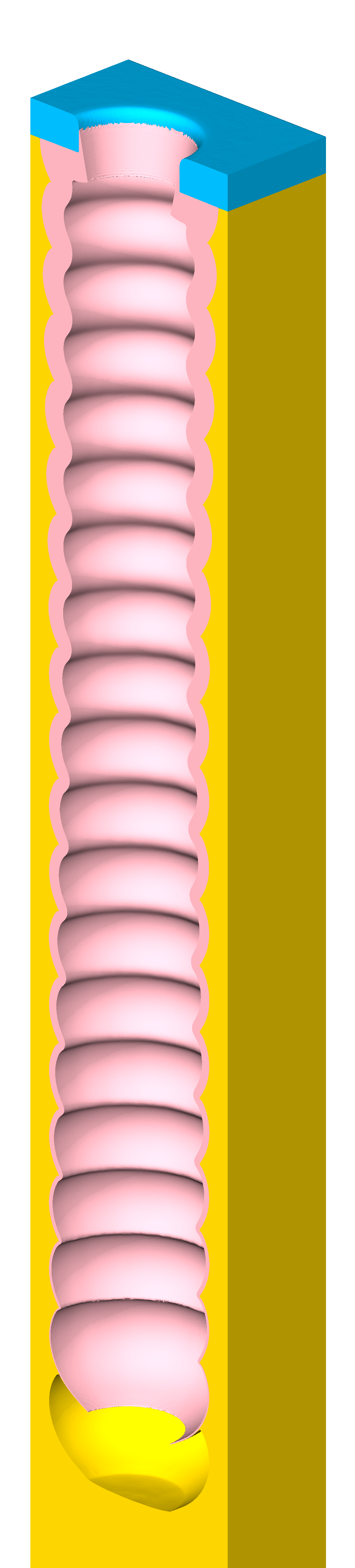

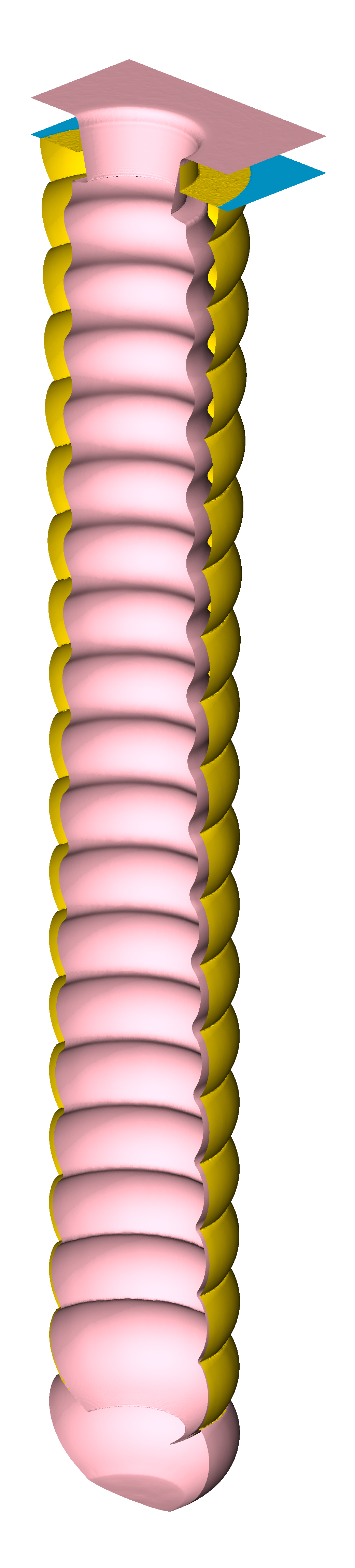

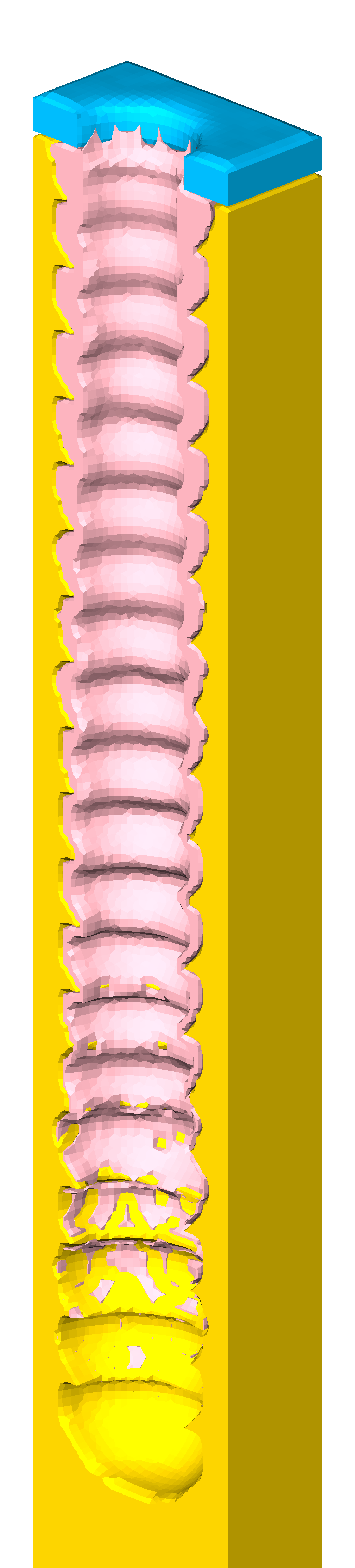

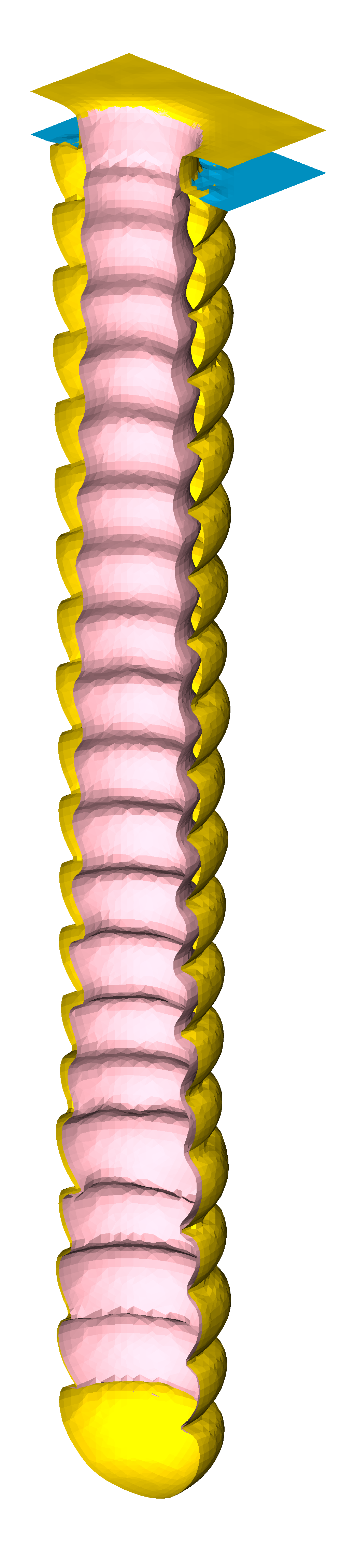

A.3 Simple Bosch Process

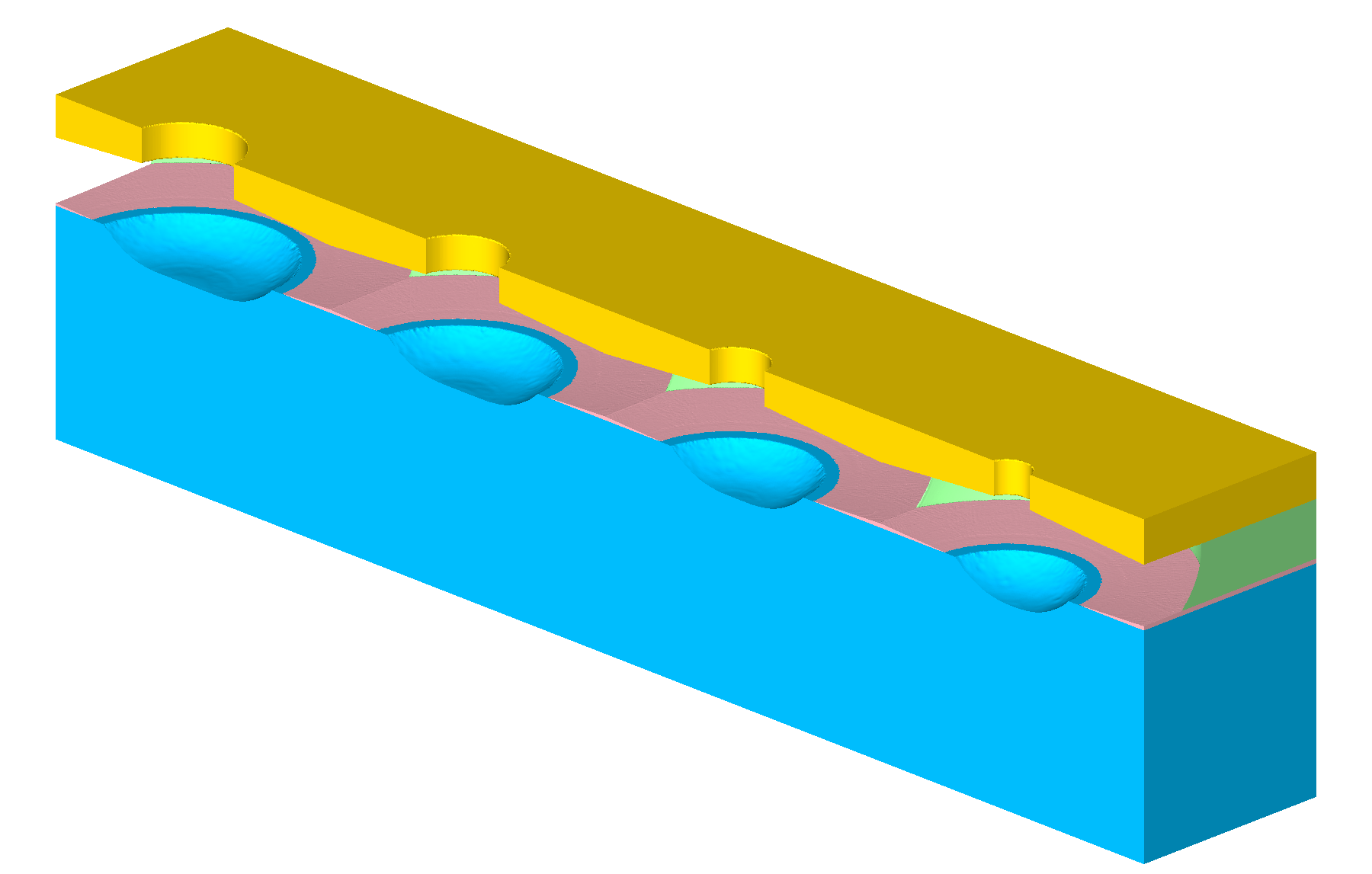

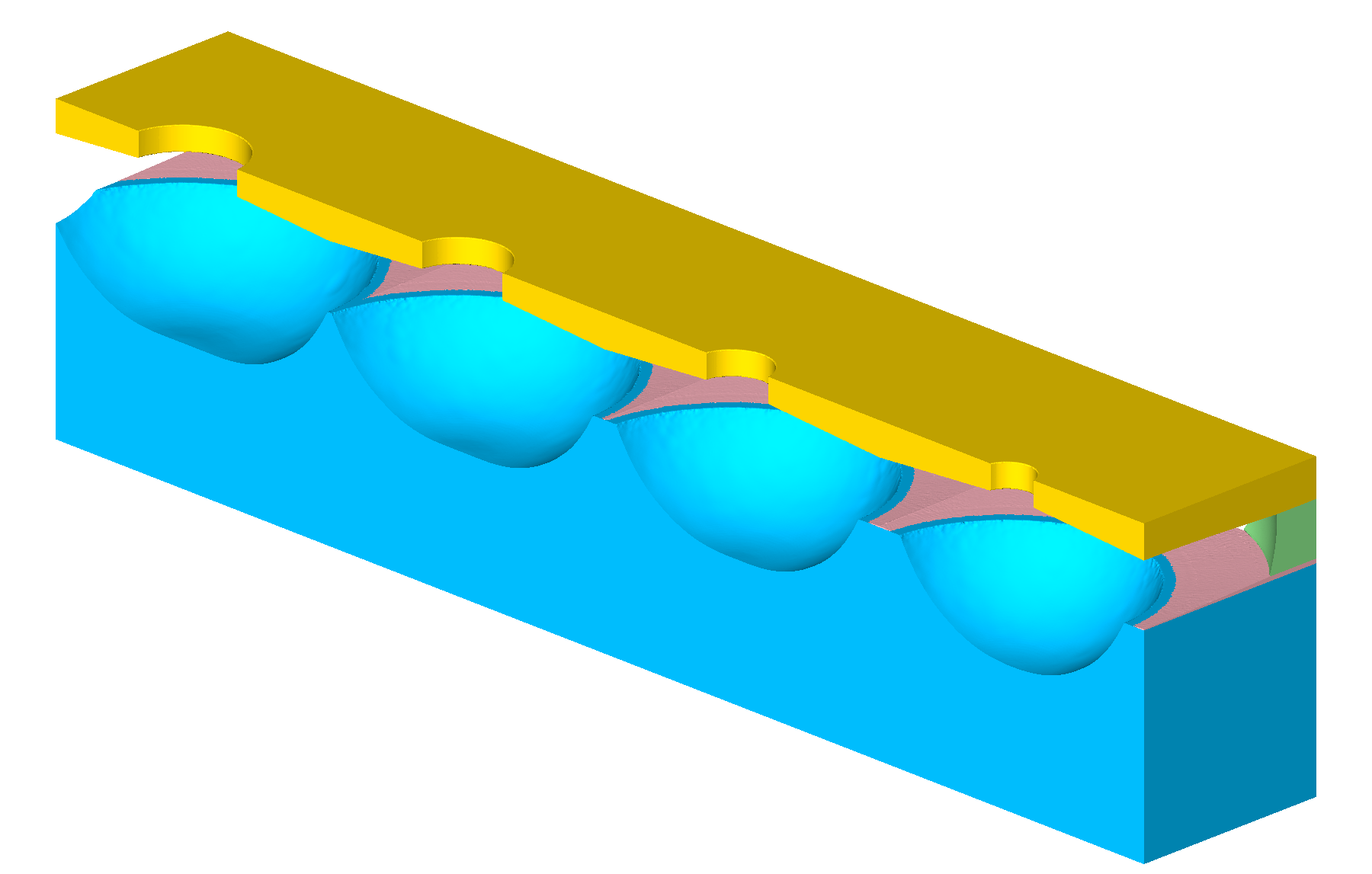

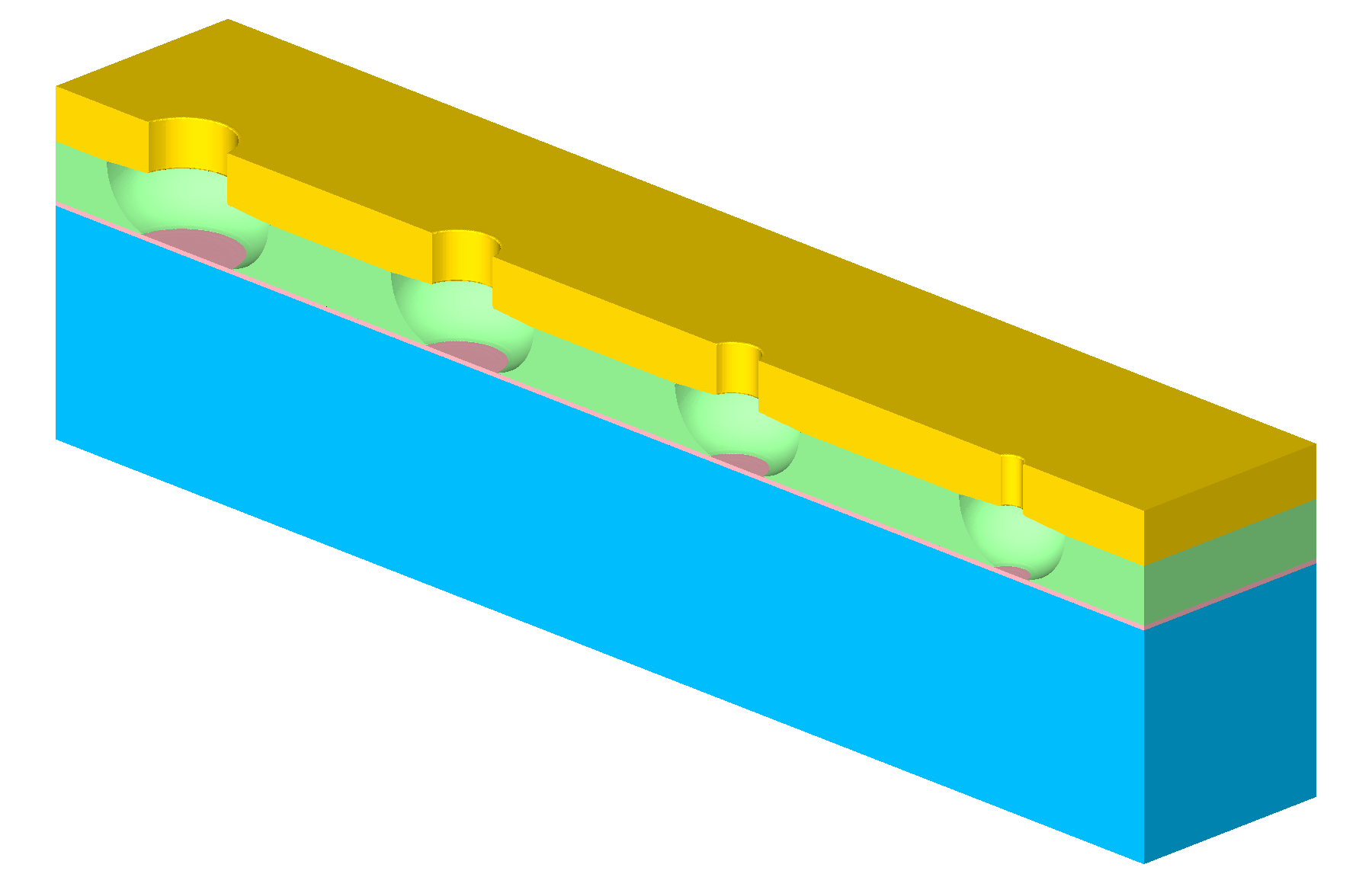

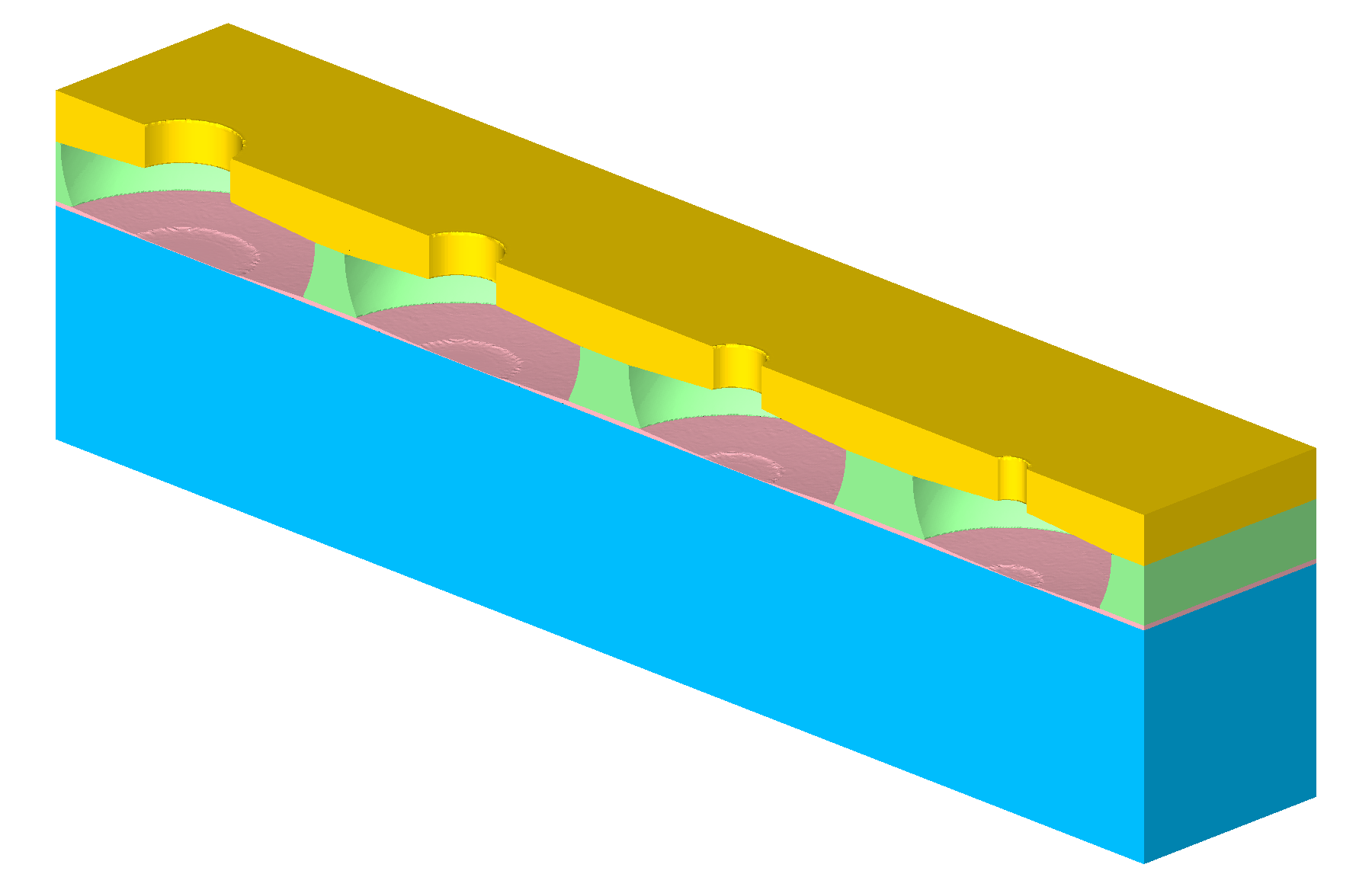

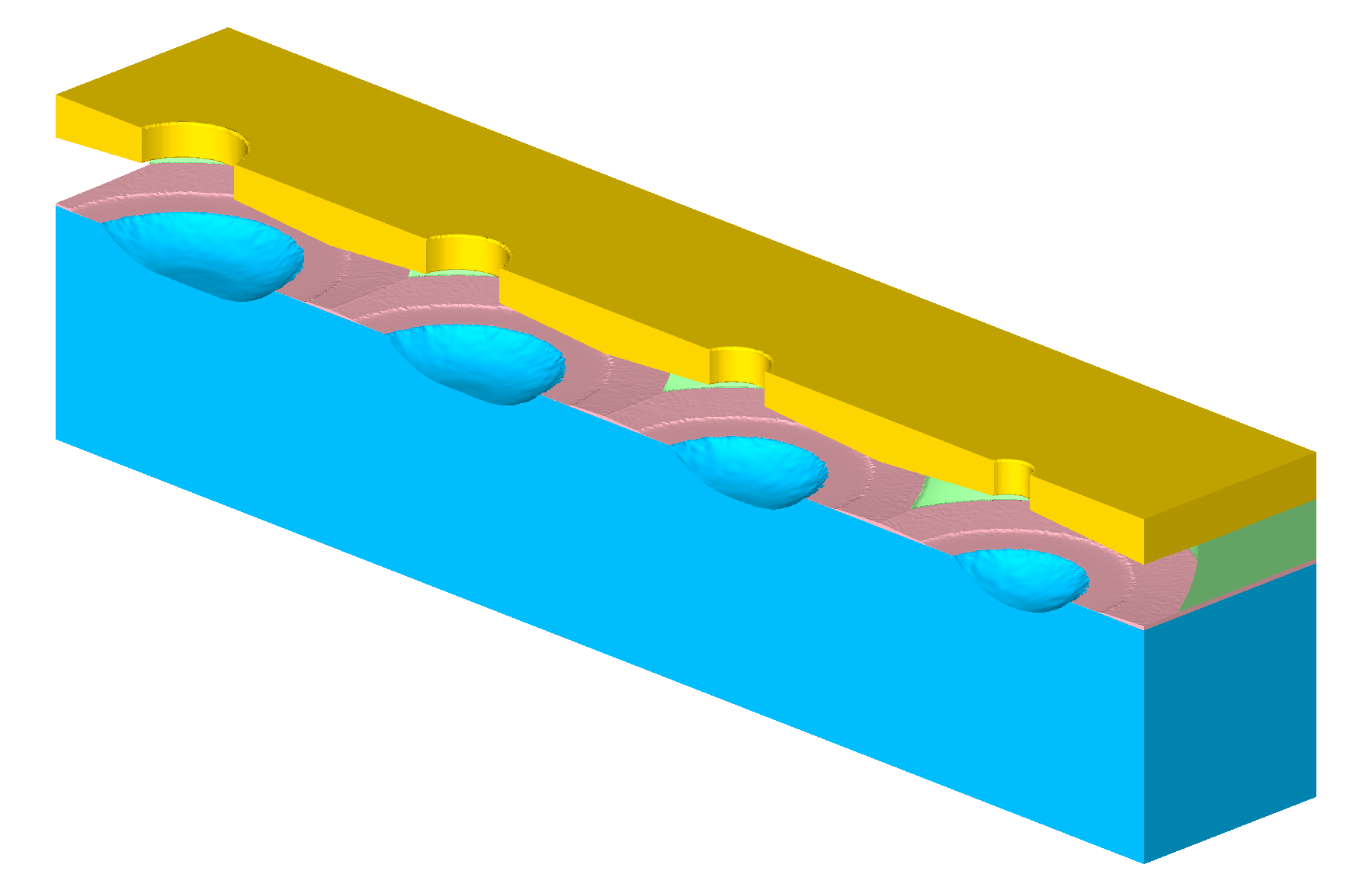

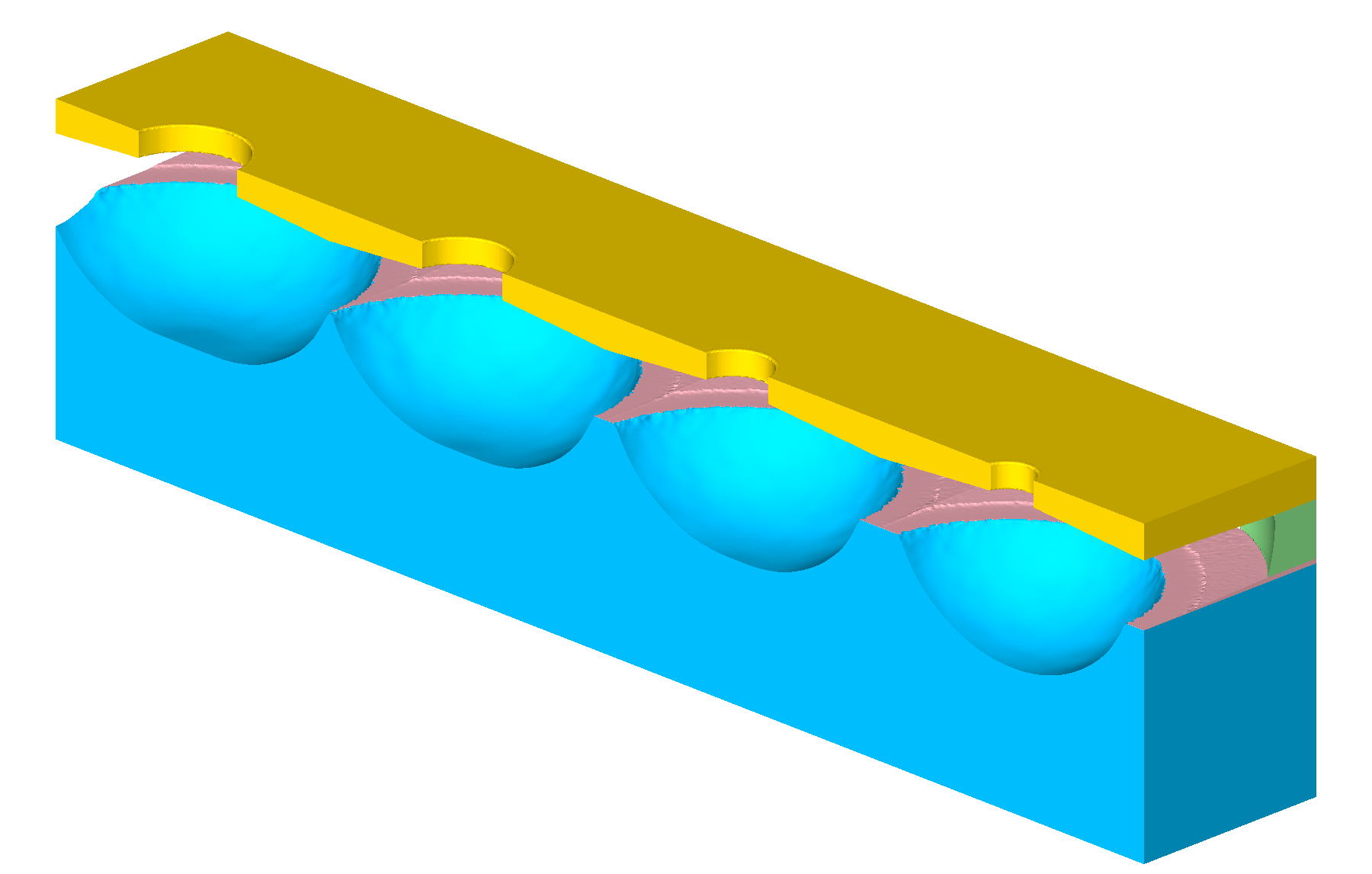

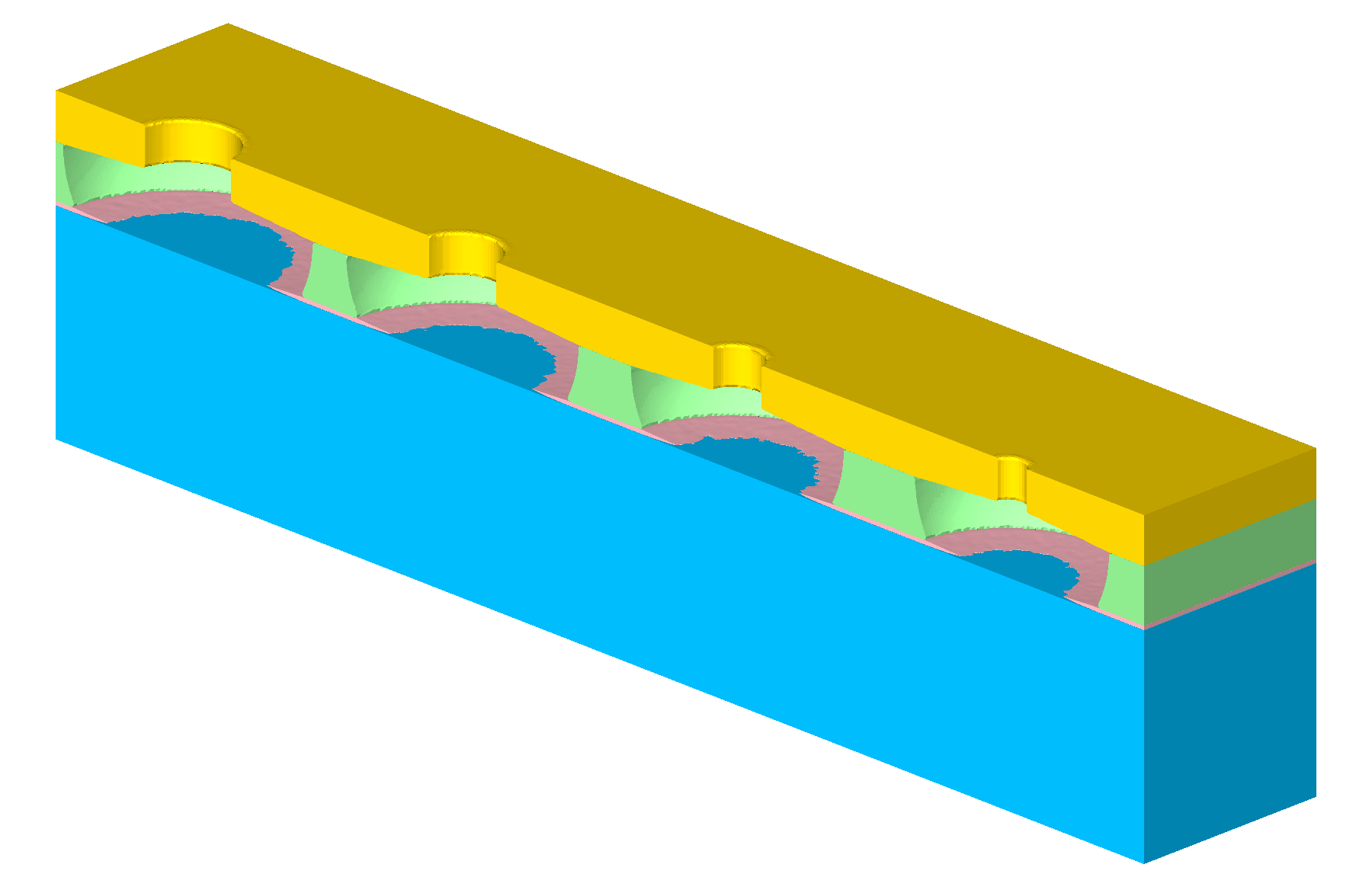

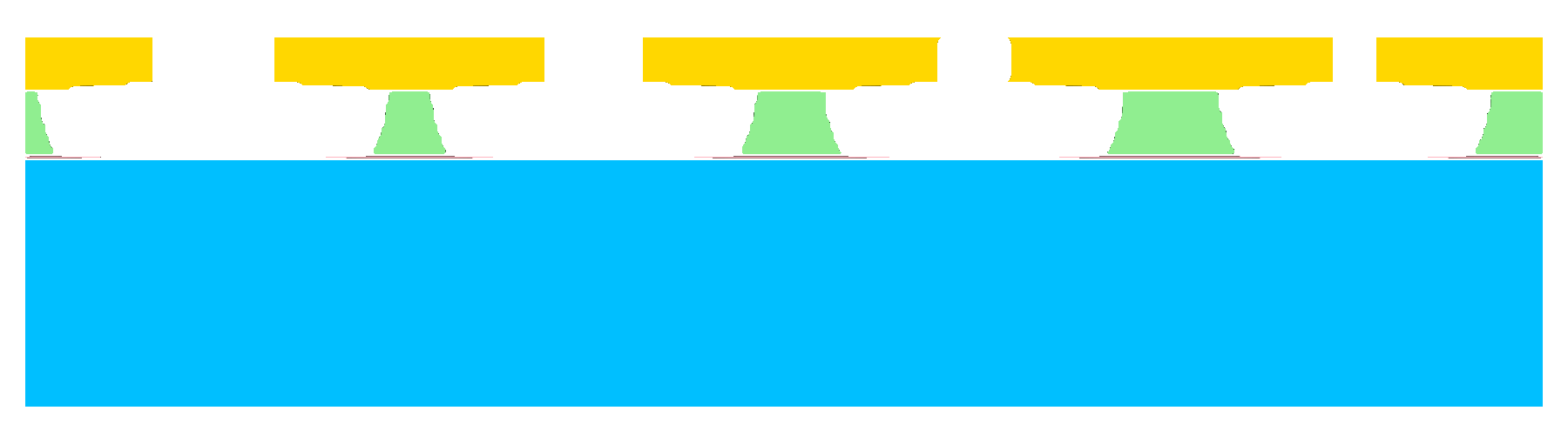

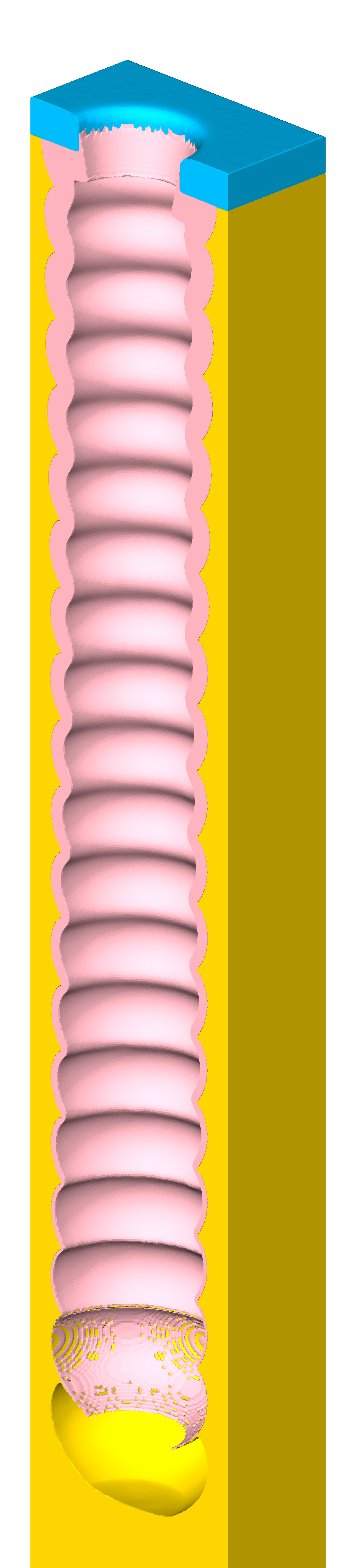

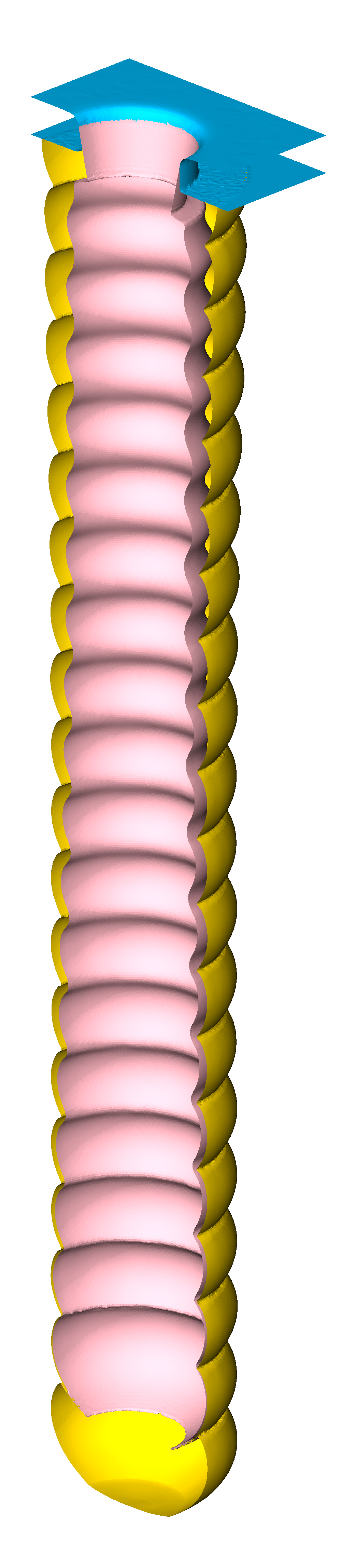

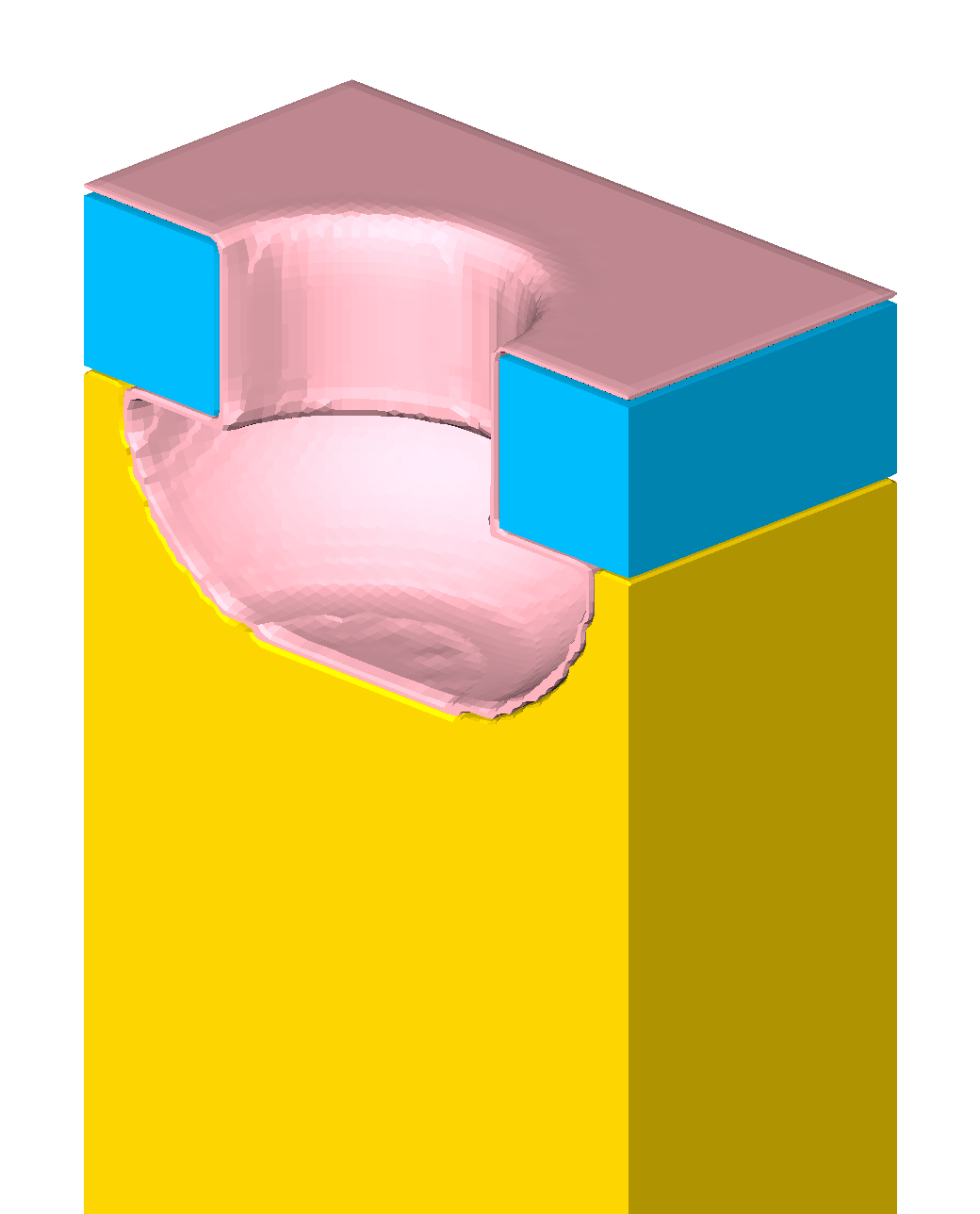

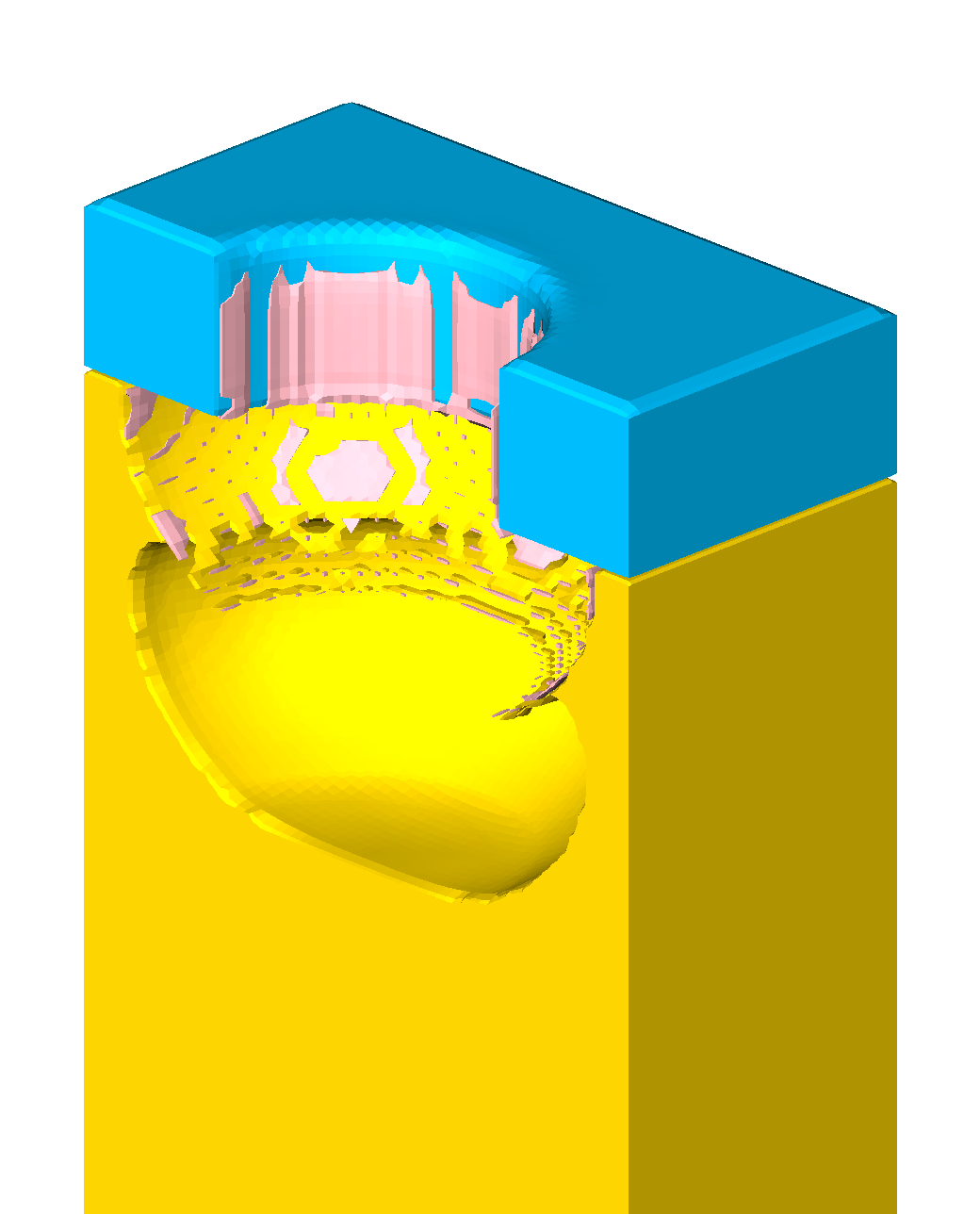

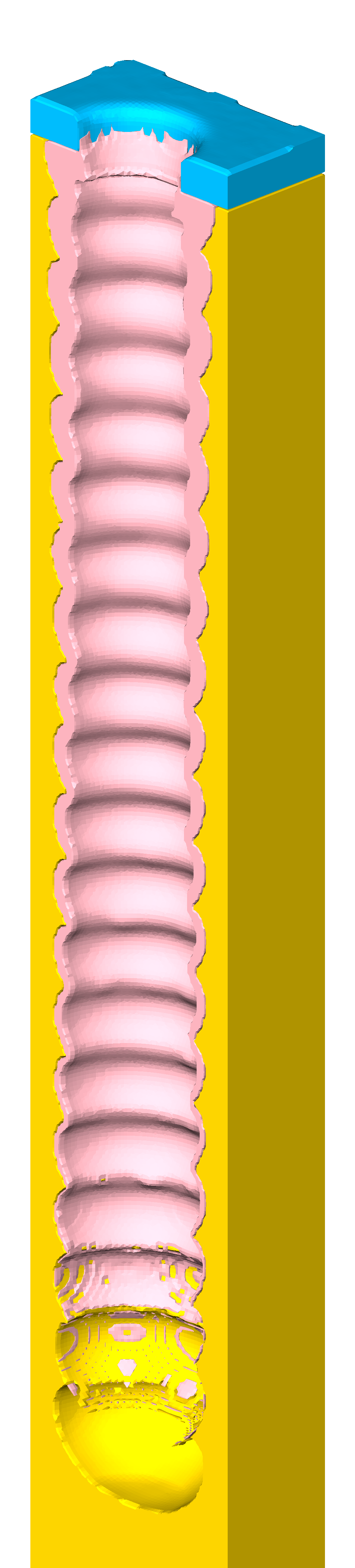

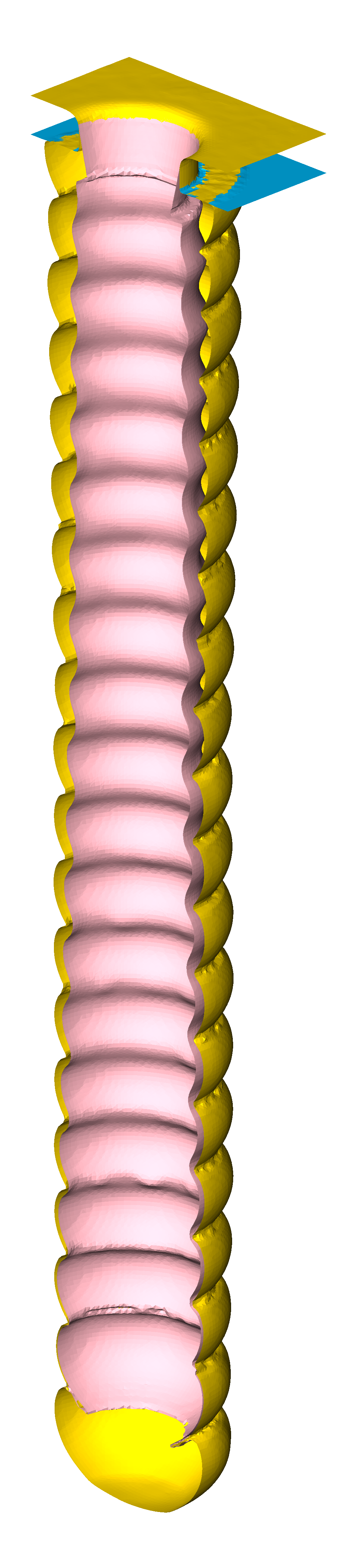

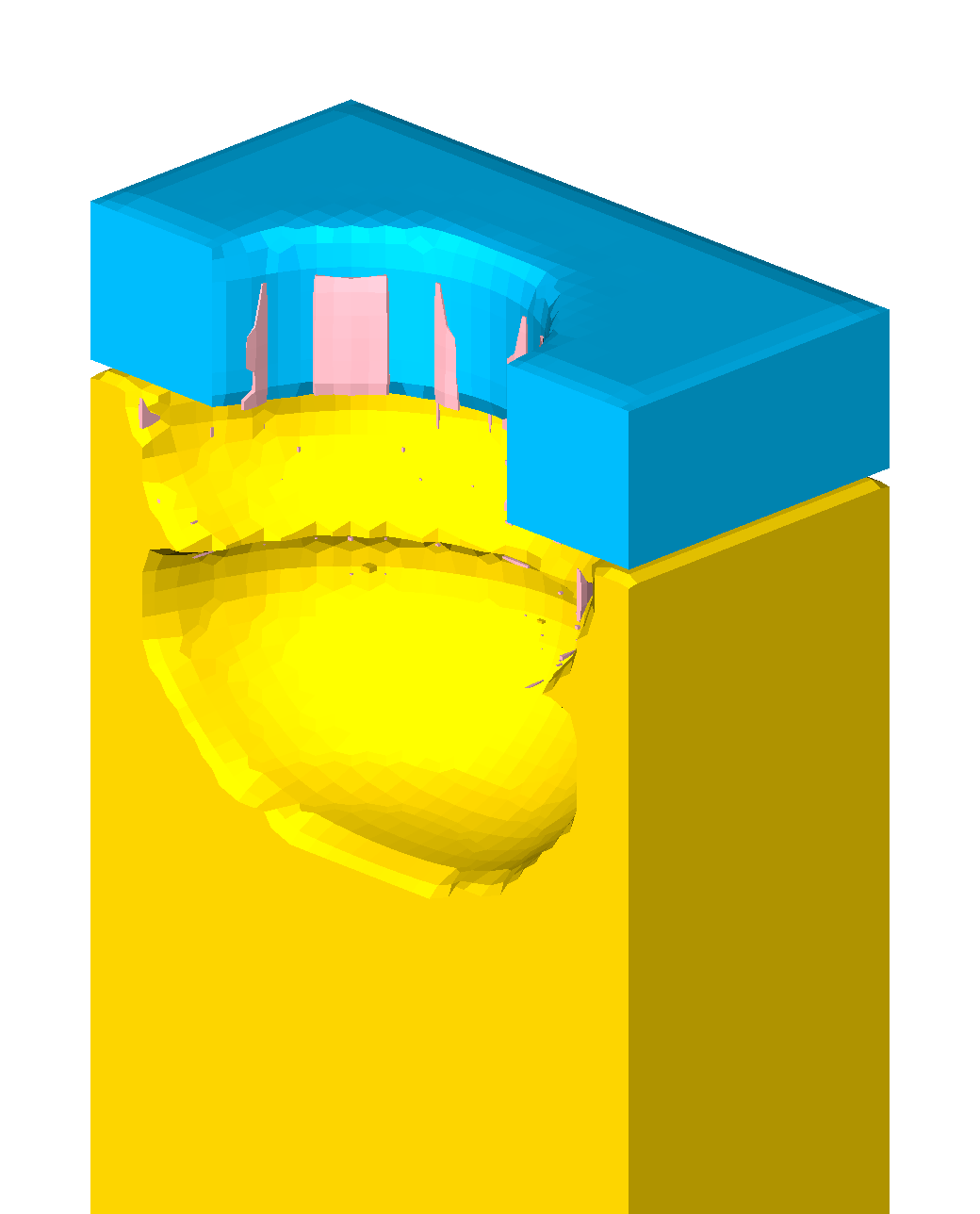

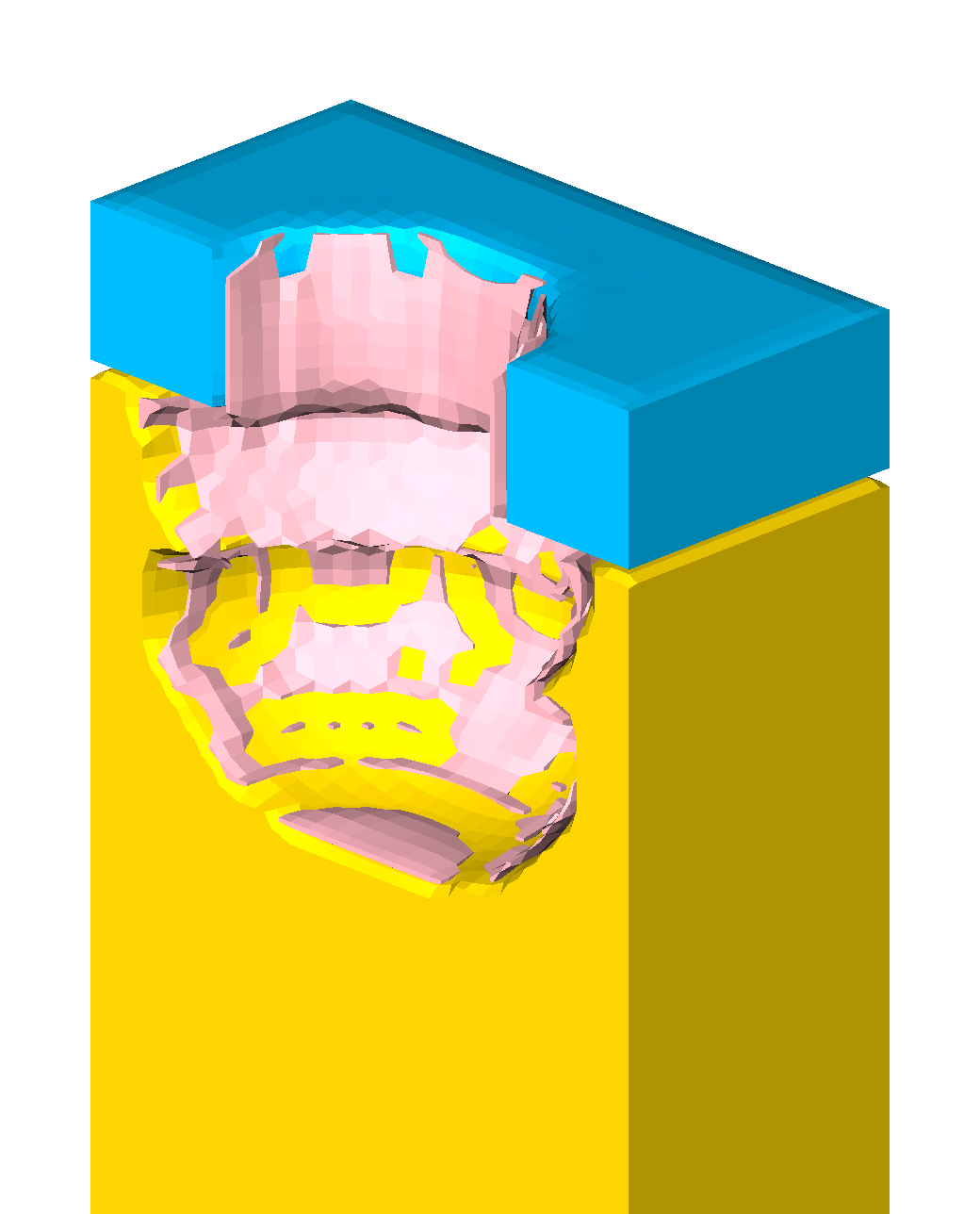

Figure A.8: Material regions of the simple Bosch process test case for resolution . (a)-(e):

Material regions after each of the first 5 processing steps, i.e., alternating deposition and etching steps. (f): Final material regions after 20 cycles. (g):

Final material layers after 20 cycles. The same results for lower resolutions

,

, and

are provided in Figures A.9-

A.11.