Phenomenological Single-Particle

\(\newcommand{\footnotename}{footnote}\)

\(\def \LWRfootnote {1}\)

\(\newcommand {\footnote }[2][\LWRfootnote ]{{}^{\mathrm {#1}}}\)

\(\newcommand {\footnotemark }[1][\LWRfootnote ]{{}^{\mathrm {#1}}}\)

\(\let \LWRorighspace \hspace \)

\(\renewcommand {\hspace }{\ifstar \LWRorighspace \LWRorighspace }\)

\(\newcommand {\mathnormal }[1]{{#1}}\)

\(\newcommand \ensuremath [1]{#1}\)

\(\newcommand {\LWRframebox }[2][]{\fbox {#2}} \newcommand {\framebox }[1][]{\LWRframebox } \)

\(\newcommand {\setlength }[2]{}\)

\(\newcommand {\addtolength }[2]{}\)

\(\newcommand {\setcounter }[2]{}\)

\(\newcommand {\addtocounter }[2]{}\)

\(\newcommand {\arabic }[1]{}\)

\(\newcommand {\number }[1]{}\)

\(\newcommand {\noalign }[1]{\text {#1}\notag \\}\)

\(\newcommand {\cline }[1]{}\)

\(\newcommand {\directlua }[1]{\text {(directlua)}}\)

\(\newcommand {\luatexdirectlua }[1]{\text {(directlua)}}\)

\(\newcommand {\protect }{}\)

\(\def \LWRabsorbnumber #1 {}\)

\(\def \LWRabsorbquotenumber "#1 {}\)

\(\newcommand {\LWRabsorboption }[1][]{}\)

\(\newcommand {\LWRabsorbtwooptions }[1][]{\LWRabsorboption }\)

\(\def \mathchar {\ifnextchar "\LWRabsorbquotenumber \LWRabsorbnumber }\)

\(\def \mathcode #1={\mathchar }\)

\(\let \delcode \mathcode \)

\(\let \delimiter \mathchar \)

\(\def \oe {\unicode {x0153}}\)

\(\def \OE {\unicode {x0152}}\)

\(\def \ae {\unicode {x00E6}}\)

\(\def \AE {\unicode {x00C6}}\)

\(\def \aa {\unicode {x00E5}}\)

\(\def \AA {\unicode {x00C5}}\)

\(\def \o {\unicode {x00F8}}\)

\(\def \O {\unicode {x00D8}}\)

\(\def \l {\unicode {x0142}}\)

\(\def \L {\unicode {x0141}}\)

\(\def \ss {\unicode {x00DF}}\)

\(\def \SS {\unicode {x1E9E}}\)

\(\def \dag {\unicode {x2020}}\)

\(\def \ddag {\unicode {x2021}}\)

\(\def \P {\unicode {x00B6}}\)

\(\def \copyright {\unicode {x00A9}}\)

\(\def \pounds {\unicode {x00A3}}\)

\(\let \LWRref \ref \)

\(\renewcommand {\ref }{\ifstar \LWRref \LWRref }\)

\( \newcommand {\multicolumn }[3]{#3}\)

\(\require {textcomp}\)

\(\newcommand {\intertext }[1]{\text {#1}\notag \\}\)

\(\let \Hat \hat \)

\(\let \Check \check \)

\(\let \Tilde \tilde \)

\(\let \Acute \acute \)

\(\let \Grave \grave \)

\(\let \Dot \dot \)

\(\let \Ddot \ddot \)

\(\let \Breve \breve \)

\(\let \Bar \bar \)

\(\let \Vec \vec \)

\(\require {mathtools}\)

\(\newenvironment {crampedsubarray}[1]{}{}\)

\(\newcommand {\smashoperator }[2][]{#2\limits }\)

\(\newcommand {\SwapAboveDisplaySkip }{}\)

\(\newcommand {\LaTeXunderbrace }[1]{\underbrace {#1}}\)

\(\newcommand {\LaTeXoverbrace }[1]{\overbrace {#1}}\)

\(\newcommand {\LWRmultlined }[1][]{\begin {multline*}}\)

\(\newenvironment {multlined}[1][]{\LWRmultlined }{\end {multline*}}\)

\(\let \LWRorigshoveleft \shoveleft \)

\(\renewcommand {\shoveleft }[1][]{\LWRorigshoveleft }\)

\(\let \LWRorigshoveright \shoveright \)

\(\renewcommand {\shoveright }[1][]{\LWRorigshoveright }\)

\(\newcommand {\shortintertext }[1]{\text {#1}\notag \\}\)

\(\newcommand {\vcentcolon }{\mathrel {\unicode {x2236}}}\)

\(\newcommand {\tothe }[1]{^{#1}}\)

\(\newcommand {\raiseto }[2]{{#2}^{#1}}\)

\(\newcommand {\LWRsiunitxEND }{}\)

\(\def \LWRsiunitxang #1;#2;#3;#4\LWRsiunitxEND {\ifblank {#1}{}{\num {#1}\degree }\ifblank {#2}{}{\num {#2}^{\unicode {x2032}}}\ifblank {#3}{}{\num {#3}^{\unicode {x2033}}}}\)

\(\newcommand {\ang }[2][]{\LWRsiunitxang #2;;;\LWRsiunitxEND }\)

\(\def \LWRsiunitxdistribunit {}\)

\(\newcommand {\LWRsiunitxENDTWO }{}\)

\(\def \LWRsiunitxprintdecimalsubtwo #1,#2,#3\LWRsiunitxENDTWO {\ifblank {#1}{0}{\mathrm {#1}}\ifblank {#2}{}{{\LWRsiunitxdecimal }\mathrm {#2}}}\)

\(\def \LWRsiunitxprintdecimalsub #1.#2.#3\LWRsiunitxEND {\LWRsiunitxprintdecimalsubtwo #1,,\LWRsiunitxENDTWO \ifblank {#2}{}{{\LWRsiunitxdecimal }\LWRsiunitxprintdecimalsubtwo

#2,,\LWRsiunitxENDTWO }}\)

\(\newcommand {\LWRsiunitxprintdecimal }[1]{\LWRsiunitxprintdecimalsub #1...\LWRsiunitxEND }\)

\(\def \LWRsiunitxnumplus #1+#2+#3\LWRsiunitxEND {\ifblank {#2}{\LWRsiunitxprintdecimal {#1}}{\ifblank {#1}{\LWRsiunitxprintdecimal {#2}}{\LWRsiunitxprintdecimal {#1}\unicode

{x02B}\LWRsiunitxprintdecimal {#2}}}\LWRsiunitxdistribunit }\)

\(\def \LWRsiunitxnumminus #1-#2-#3\LWRsiunitxEND {\ifblank {#2}{\LWRsiunitxnumplus #1+++\LWRsiunitxEND }{\ifblank {#1}{}{\LWRsiunitxprintdecimal {#1}}\unicode {x02212}\LWRsiunitxprintdecimal

{#2}\LWRsiunitxdistribunit }}\)

\(\def \LWRsiunitxnumpmmacro #1\pm #2\pm #3\LWRsiunitxEND {\ifblank {#2}{\LWRsiunitxnumminus #1---\LWRsiunitxEND }{\LWRsiunitxprintdecimal {#1}\unicode {x0B1}\LWRsiunitxprintdecimal

{#2}\LWRsiunitxdistribunit }}\)

\(\def \LWRsiunitxnumpm #1+-#2+-#3\LWRsiunitxEND {\ifblank {#2}{\LWRsiunitxnumpmmacro #1\pm \pm \pm \LWRsiunitxEND }{\LWRsiunitxprintdecimal {#1}\unicode {x0B1}\LWRsiunitxprintdecimal

{#2}\LWRsiunitxdistribunit }}\)

\(\newcommand {\LWRsiunitxnumscientific }[2]{\ifblank {#1}{}{\ifstrequal {#1}{-}{-}{\LWRsiunitxprintdecimal {#1}\times }}10^{\LWRsiunitxprintdecimal {#2}}\LWRsiunitxdistribunit }\)

\(\def \LWRsiunitxnumD #1D#2D#3\LWRsiunitxEND {\ifblank {#2}{\LWRsiunitxnumpm #1+-+-\LWRsiunitxEND }{\mathrm {\LWRsiunitxnumscientific {#1}{#2}}}}\)

\(\def \LWRsiunitxnumd #1d#2d#3\LWRsiunitxEND {\ifblank {#2}{\LWRsiunitxnumD #1DDD\LWRsiunitxEND }{\mathrm {\LWRsiunitxnumscientific {#1}{#2}}}}\)

\(\def \LWRsiunitxnumE #1E#2E#3\LWRsiunitxEND {\ifblank {#2}{\LWRsiunitxnumd #1ddd\LWRsiunitxEND }{\mathrm {\LWRsiunitxnumscientific {#1}{#2}}}}\)

\(\def \LWRsiunitxnume #1e#2e#3\LWRsiunitxEND {\ifblank {#2}{\LWRsiunitxnumE #1EEE\LWRsiunitxEND }{\mathrm {\LWRsiunitxnumscientific {#1}{#2}}}}\)

\(\def \LWRsiunitxnumx #1x#2x#3x#4\LWRsiunitxEND {\ifblank {#2}{\LWRsiunitxnume #1eee\LWRsiunitxEND }{\ifblank {#3}{\LWRsiunitxnume #1eee\LWRsiunitxEND \times \LWRsiunitxnume

#2eee\LWRsiunitxEND }{\LWRsiunitxnume #1eee\LWRsiunitxEND \times \LWRsiunitxnume #2eee\LWRsiunitxEND \times \LWRsiunitxnume #3eee\LWRsiunitxEND }}}\)

\(\newcommand {\num }[2][]{\LWRsiunitxnumx #2xxxxx\LWRsiunitxEND }\)

\(\newcommand {\si }[2][]{\mathrm {\gsubstitute {#2}{~}{\,}}}\)

\(\def \LWRsiunitxSIopt #1[#2]#3{\def \LWRsiunitxdistribunit {\,\si {#3}}{#2}\num {#1}\def \LWRsiunitxdistribunit {}}\)

\(\newcommand {\LWRsiunitxSI }[2]{\def \LWRsiunitxdistribunit {\,\si {#2}}\num {#1}\def \LWRsiunitxdistribunit {}}\)

\(\newcommand {\SI }[2][]{\ifnextchar [{\LWRsiunitxSIopt {#2}}{\LWRsiunitxSI {#2}}}\)

\(\newcommand {\numlist }[2][]{\text {#2}}\)

\(\newcommand {\numrange }[3][]{\num {#2}\ \LWRsiunitxrangephrase \ \num {#3}}\)

\(\newcommand {\SIlist }[3][]{\text {#2}\,\si {#3}}\)

\(\newcommand {\SIrange }[4][]{\num {#2}\,#4\ \LWRsiunitxrangephrase \ \num {#3}\,#4}\)

\(\newcommand {\tablenum }[2][]{\mathrm {#2}}\)

\(\newcommand {\ampere }{\mathrm {A}}\)

\(\newcommand {\candela }{\mathrm {cd}}\)

\(\newcommand {\kelvin }{\mathrm {K}}\)

\(\newcommand {\kilogram }{\mathrm {kg}}\)

\(\newcommand {\metre }{\mathrm {m}}\)

\(\newcommand {\mole }{\mathrm {mol}}\)

\(\newcommand {\second }{\mathrm {s}}\)

\(\newcommand {\becquerel }{\mathrm {Bq}}\)

\(\newcommand {\degreeCelsius }{\unicode {x2103}}\)

\(\newcommand {\coulomb }{\mathrm {C}}\)

\(\newcommand {\farad }{\mathrm {F}}\)

\(\newcommand {\gray }{\mathrm {Gy}}\)

\(\newcommand {\hertz }{\mathrm {Hz}}\)

\(\newcommand {\henry }{\mathrm {H}}\)

\(\newcommand {\joule }{\mathrm {J}}\)

\(\newcommand {\katal }{\mathrm {kat}}\)

\(\newcommand {\lumen }{\mathrm {lm}}\)

\(\newcommand {\lux }{\mathrm {lx}}\)

\(\newcommand {\newton }{\mathrm {N}}\)

\(\newcommand {\ohm }{\mathrm {\Omega }}\)

\(\newcommand {\pascal }{\mathrm {Pa}}\)

\(\newcommand {\radian }{\mathrm {rad}}\)

\(\newcommand {\siemens }{\mathrm {S}}\)

\(\newcommand {\sievert }{\mathrm {Sv}}\)

\(\newcommand {\steradian }{\mathrm {sr}}\)

\(\newcommand {\tesla }{\mathrm {T}}\)

\(\newcommand {\volt }{\mathrm {V}}\)

\(\newcommand {\watt }{\mathrm {W}}\)

\(\newcommand {\weber }{\mathrm {Wb}}\)

\(\newcommand {\day }{\mathrm {d}}\)

\(\newcommand {\degree }{\mathrm {^\circ }}\)

\(\newcommand {\hectare }{\mathrm {ha}}\)

\(\newcommand {\hour }{\mathrm {h}}\)

\(\newcommand {\litre }{\mathrm {l}}\)

\(\newcommand {\liter }{\mathrm {L}}\)

\(\newcommand {\arcminute }{^\prime }\)

\(\newcommand {\minute }{\mathrm {min}}\)

\(\newcommand {\arcsecond }{^{\prime \prime }}\)

\(\newcommand {\tonne }{\mathrm {t}}\)

\(\newcommand {\astronomicalunit }{au}\)

\(\newcommand {\atomicmassunit }{u}\)

\(\newcommand {\bohr }{\mathit {a}_0}\)

\(\newcommand {\clight }{\mathit {c}_0}\)

\(\newcommand {\dalton }{\mathrm {D}_\mathrm {a}}\)

\(\newcommand {\electronmass }{\mathit {m}_{\mathrm {e}}}\)

\(\newcommand {\electronvolt }{\mathrm {eV}}\)

\(\newcommand {\elementarycharge }{\mathit {e}}\)

\(\newcommand {\hartree }{\mathit {E}_{\mathrm {h}}}\)

\(\newcommand {\planckbar }{\mathit {\unicode {x210F}}}\)

\(\newcommand {\angstrom }{\mathrm {\unicode {x212B}}}\)

\(\let \LWRorigbar \bar \)

\(\newcommand {\bar }{\mathrm {bar}}\)

\(\newcommand {\barn }{\mathrm {b}}\)

\(\newcommand {\bel }{\mathrm {B}}\)

\(\newcommand {\decibel }{\mathrm {dB}}\)

\(\newcommand {\knot }{\mathrm {kn}}\)

\(\newcommand {\mmHg }{\mathrm {mmHg}}\)

\(\newcommand {\nauticalmile }{\mathrm {M}}\)

\(\newcommand {\neper }{\mathrm {Np}}\)

\(\newcommand {\yocto }{\mathrm {y}}\)

\(\newcommand {\zepto }{\mathrm {z}}\)

\(\newcommand {\atto }{\mathrm {a}}\)

\(\newcommand {\femto }{\mathrm {f}}\)

\(\newcommand {\pico }{\mathrm {p}}\)

\(\newcommand {\nano }{\mathrm {n}}\)

\(\newcommand {\micro }{\mathrm {\unicode {x00B5}}}\)

\(\newcommand {\milli }{\mathrm {m}}\)

\(\newcommand {\centi }{\mathrm {c}}\)

\(\newcommand {\deci }{\mathrm {d}}\)

\(\newcommand {\deca }{\mathrm {da}}\)

\(\newcommand {\hecto }{\mathrm {h}}\)

\(\newcommand {\kilo }{\mathrm {k}}\)

\(\newcommand {\mega }{\mathrm {M}}\)

\(\newcommand {\giga }{\mathrm {G}}\)

\(\newcommand {\tera }{\mathrm {T}}\)

\(\newcommand {\peta }{\mathrm {P}}\)

\(\newcommand {\exa }{\mathrm {E}}\)

\(\newcommand {\zetta }{\mathrm {Z}}\)

\(\newcommand {\yotta }{\mathrm {Y}}\)

\(\newcommand {\percent }{\mathrm {\%}}\)

\(\newcommand {\meter }{\mathrm {m}}\)

\(\newcommand {\metre }{\mathrm {m}}\)

\(\newcommand {\gram }{\mathrm {g}}\)

\(\newcommand {\kg }{\kilo \gram }\)

\(\newcommand {\of }[1]{_{\mathrm {#1}}}\)

\(\newcommand {\squared }{^2}\)

\(\newcommand {\square }[1]{\mathrm {#1}^2}\)

\(\newcommand {\cubed }{^3}\)

\(\newcommand {\cubic }[1]{\mathrm {#1}^3}\)

\(\newcommand {\per }{\,\mathrm {/}}\)

\(\newcommand {\celsius }{\unicode {x2103}}\)

\(\newcommand {\fg }{\femto \gram }\)

\(\newcommand {\pg }{\pico \gram }\)

\(\newcommand {\ng }{\nano \gram }\)

\(\newcommand {\ug }{\micro \gram }\)

\(\newcommand {\mg }{\milli \gram }\)

\(\newcommand {\g }{\gram }\)

\(\newcommand {\kg }{\kilo \gram }\)

\(\newcommand {\amu }{\mathrm {u}}\)

\(\newcommand {\pm }{\pico \metre }\)

\(\newcommand {\nm }{\nano \metre }\)

\(\newcommand {\um }{\micro \metre }\)

\(\newcommand {\mm }{\milli \metre }\)

\(\newcommand {\cm }{\centi \metre }\)

\(\newcommand {\dm }{\deci \metre }\)

\(\newcommand {\m }{\metre }\)

\(\newcommand {\km }{\kilo \metre }\)

\(\newcommand {\as }{\atto \second }\)

\(\newcommand {\fs }{\femto \second }\)

\(\newcommand {\ps }{\pico \second }\)

\(\newcommand {\ns }{\nano \second }\)

\(\newcommand {\us }{\micro \second }\)

\(\newcommand {\ms }{\milli \second }\)

\(\newcommand {\s }{\second }\)

\(\newcommand {\fmol }{\femto \mol }\)

\(\newcommand {\pmol }{\pico \mol }\)

\(\newcommand {\nmol }{\nano \mol }\)

\(\newcommand {\umol }{\micro \mol }\)

\(\newcommand {\mmol }{\milli \mol }\)

\(\newcommand {\mol }{\mol }\)

\(\newcommand {\kmol }{\kilo \mol }\)

\(\newcommand {\pA }{\pico \ampere }\)

\(\newcommand {\nA }{\nano \ampere }\)

\(\newcommand {\uA }{\micro \ampere }\)

\(\newcommand {\mA }{\milli \ampere }\)

\(\newcommand {\A }{\ampere }\)

\(\newcommand {\kA }{\kilo \ampere }\)

\(\newcommand {\ul }{\micro \litre }\)

\(\newcommand {\ml }{\milli \litre }\)

\(\newcommand {\l }{\litre }\)

\(\newcommand {\hl }{\hecto \litre }\)

\(\newcommand {\uL }{\micro \liter }\)

\(\newcommand {\mL }{\milli \liter }\)

\(\newcommand {\L }{\liter }\)

\(\newcommand {\hL }{\hecto \liter }\)

\(\newcommand {\mHz }{\milli \hertz }\)

\(\newcommand {\Hz }{\hertz }\)

\(\newcommand {\kHz }{\kilo \hertz }\)

\(\newcommand {\MHz }{\mega \hertz }\)

\(\newcommand {\GHz }{\giga \hertz }\)

\(\newcommand {\THz }{\tera \hertz }\)

\(\newcommand {\mN }{\milli \newton }\)

\(\newcommand {\N }{\newton }\)

\(\newcommand {\kN }{\kilo \newton }\)

\(\newcommand {\MN }{\mega \newton }\)

\(\newcommand {\Pa }{\pascal }\)

\(\newcommand {\kPa }{\kilo \pascal }\)

\(\newcommand {\MPa }{\mega \pascal }\)

\(\newcommand {\GPa }{\giga \pascal }\)

\(\newcommand {\mohm }{\milli \ohm }\)

\(\newcommand {\kohm }{\kilo \ohm }\)

\(\newcommand {\Mohm }{\mega \ohm }\)

\(\newcommand {\pV }{\pico \volt }\)

\(\newcommand {\nV }{\nano \volt }\)

\(\newcommand {\uV }{\micro \volt }\)

\(\newcommand {\mV }{\milli \volt }\)

\(\newcommand {\V }{\volt }\)

\(\newcommand {\kV }{\kilo \volt }\)

\(\newcommand {\W }{\watt }\)

\(\newcommand {\uW }{\micro \watt }\)

\(\newcommand {\mW }{\milli \watt }\)

\(\newcommand {\kW }{\kilo \watt }\)

\(\newcommand {\MW }{\mega \watt }\)

\(\newcommand {\GW }{\giga \watt }\)

\(\newcommand {\J }{\joule }\)

\(\newcommand {\uJ }{\micro \joule }\)

\(\newcommand {\mJ }{\milli \joule }\)

\(\newcommand {\kJ }{\kilo \joule }\)

\(\newcommand {\eV }{\electronvolt }\)

\(\newcommand {\meV }{\milli \electronvolt }\)

\(\newcommand {\keV }{\kilo \electronvolt }\)

\(\newcommand {\MeV }{\mega \electronvolt }\)

\(\newcommand {\GeV }{\giga \electronvolt }\)

\(\newcommand {\TeV }{\tera \electronvolt }\)

\(\newcommand {\kWh }{\kilo \watt \hour }\)

\(\newcommand {\F }{\farad }\)

\(\newcommand {\fF }{\femto \farad }\)

\(\newcommand {\pF }{\pico \farad }\)

\(\newcommand {\K }{\mathrm {K}}\)

\(\newcommand {\dB }{\mathrm {dB}}\)

\(\newcommand {\kibi }{\mathrm {Ki}}\)

\(\newcommand {\mebi }{\mathrm {Mi}}\)

\(\newcommand {\gibi }{\mathrm {Gi}}\)

\(\newcommand {\tebi }{\mathrm {Ti}}\)

\(\newcommand {\pebi }{\mathrm {Pi}}\)

\(\newcommand {\exbi }{\mathrm {Ei}}\)

\(\newcommand {\zebi }{\mathrm {Zi}}\)

\(\newcommand {\yobi }{\mathrm {Yi}}\)

\(\let \unit \si \)

\(\let \qty \SI \)

\(\let \qtylist \SIlist \)

\(\let \qtyrange \SIrange \)

\(\let \numproduct \num \)

\(\let \qtyproduct \SI \)

\(\let \complexnum \num \)

\(\newcommand {\complexqty }[3][]{(\complexnum {#2})\si {#3}}\)

\(\newcommand {\LWRsubmultirow }[2][]{#2}\)

\(\newcommand {\LWRmultirow }[2][]{\LWRsubmultirow }\)

\(\newcommand {\multirow }[2][]{\LWRmultirow }\)

\(\newcommand {\mrowcell }{}\)

\(\newcommand {\mcolrowcell }{}\)

\(\newcommand {\STneed }[1]{}\)

\(\newcommand {\toprule }[1][]{\hline }\)

\(\let \midrule \toprule \)

\(\let \bottomrule \toprule \)

\(\def \LWRbooktabscmidruleparen (#1)#2{}\)

\(\newcommand {\LWRbooktabscmidrulenoparen }[1]{}\)

\(\newcommand {\cmidrule }[1][]{\ifnextchar (\LWRbooktabscmidruleparen \LWRbooktabscmidrulenoparen }\)

\(\newcommand {\morecmidrules }{}\)

\(\newcommand {\specialrule }[3]{\hline }\)

\(\newcommand {\addlinespace }[1][]{}\)

\(\newcommand {\tcbset }[1]{}\)

\(\newcommand {\tcbsetforeverylayer }[1]{}\)

\(\newcommand {\tcbox }[2][]{\boxed {\text {#2}}}\)

\(\newcommand {\tcboxfit }[2][]{\boxed {#2}}\)

\(\newcommand {\tcblower }{}\)

\(\newcommand {\tcbline }{}\)

\(\newcommand {\tcbtitle }{}\)

\(\newcommand {\tcbsubtitle [2][]{\mathrm {#2}}}\)

\(\newcommand {\tcboxmath }[2][]{\boxed {#2}}\)

\(\newcommand {\tcbhighmath }[2][]{\boxed {#2}}\)

\(\newcommand {\arbitraryunit }{\text {a.u.}}\)

\(\newcommand {\torr }{\text {Torr}}\)

\(\newcommand {\sccm }{\text {sccm}}\)

\(\def \LWRsiunitxrangephrase { \protect \mbox {to} }\)

\(\def \LWRsiunitxdecimal {.}\)

5.3 Reactor Loading Effect

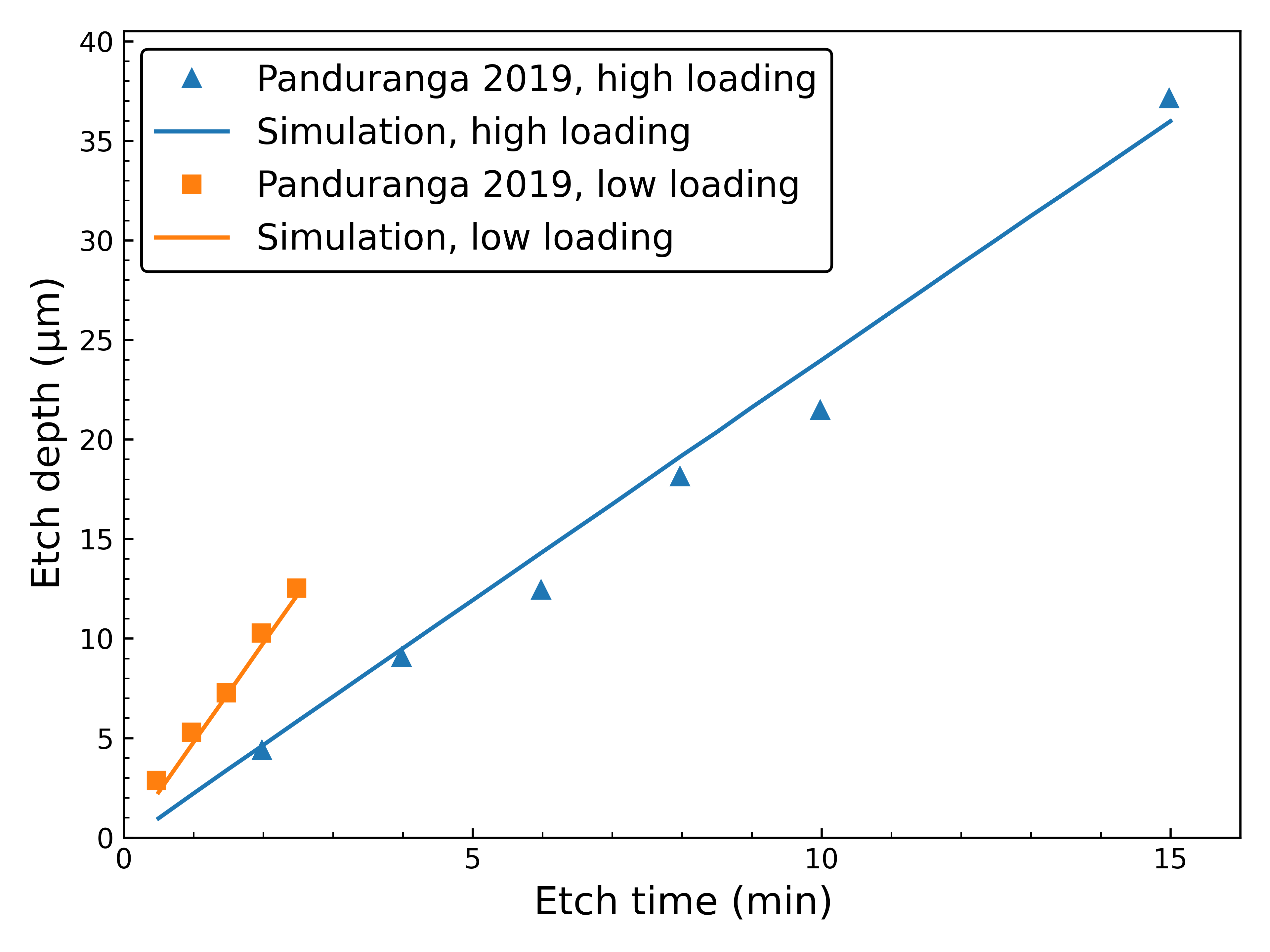

As already seen in Tab. 5.2 , there appears to be a reduction in the \(\mathit {PWR}_{\mathrm {Si}}\) for the second etch step. This is a strong indication of the presence of the

reactor loading effect, that is, a reduction in the etch rate due to an increase in the exposed wafer surface [46, 131]. With more exposed Si, which is the case for the second etch step after photoresist removal, the same number

of reactants are spread across a larger area, leading to lower etch rates. This effect is different from AR dependence due to Knudsen transport, discussed in Section 3.6.1 , since it does not

depend on characteristics of the etched feature. The reactor loading effect, often just named "loading effect", is also distinct from microloading [184] which is a variation on etch rates due to the local density of

features, even if the total exposed area is equal.

In principle, reactor loading can be modeled if the total exposed wafer area is known [46]. However, this information is not always accessible, and, additionally, such models still require fitting coefficients. Instead, the

approach taken is to treat the PWRs , thus the loading effect, as a model parameter not only for each reactor condition but also for each photoresist or hardmask configuration. At the core of this approach is the

approximation that the exposed area is constant during the etch step which is valid for low photoresist or hardmask etch rates.

This effect has been experimentally investigated by Panduranga et al. [171]. In their work, they attempt to deliberately construct a regime with lower etch rates by placing the individual chips over a larger and

unmasked silicon carrier wafer.5.1 . The final shape of the surface is measured with a mechanical profilometer.

The original authors assume that there are no limitations due to visibility, thus they calculate the PWRs from the etch depths at the center. However, since visibility effects often play a subtle role, the simulation considers

the entire geometry. The \(\mathit {PWR}_{\mathrm {Si}}\) is manually adjusted for each of the reported regimes to encounter the best fit to the reported experimental depths. The resulting parameters are disclosed in Tab. 5.4 and the time evolution of the etch depth at the center of the cylindrical opening is shown in Fig. 5.3 . The good agreement is evidence

that the approach of modeling the loading effect through treating the PWR as a fitting parameter is valid. In comparison to the original work, the values are within the range of reported etch rates for the high loading

regime (between \(2.07\) and \(\SI {2.47}{\micro \meter \per \minute }\)).

.

Low loading \(\mathit {PWR}_{\mathrm {Si}}\)

High loading \(\mathit {PWR}_{\mathrm {Si}}\)

\(\SI {4.92}{\micro \meter \per \minute }\)

\(\SI {2.40}{\micro \meter \per \minute }\)

Table 5.4: Plane-wafer etch rates for the low and high reactor loading regimes calibrated to experimental etch depths reported in [171].